Preparation method of high-performance doping strontium titanate oxide thermoelectric film

A technology of thermoelectric thin films and oxides, which is applied in the manufacture/processing of thermoelectric devices, and materials for the lead wires of thermoelectric devices, can solve the problems that restrict the practical application of thin film materials, and achieve the effect of high thermoelectric transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

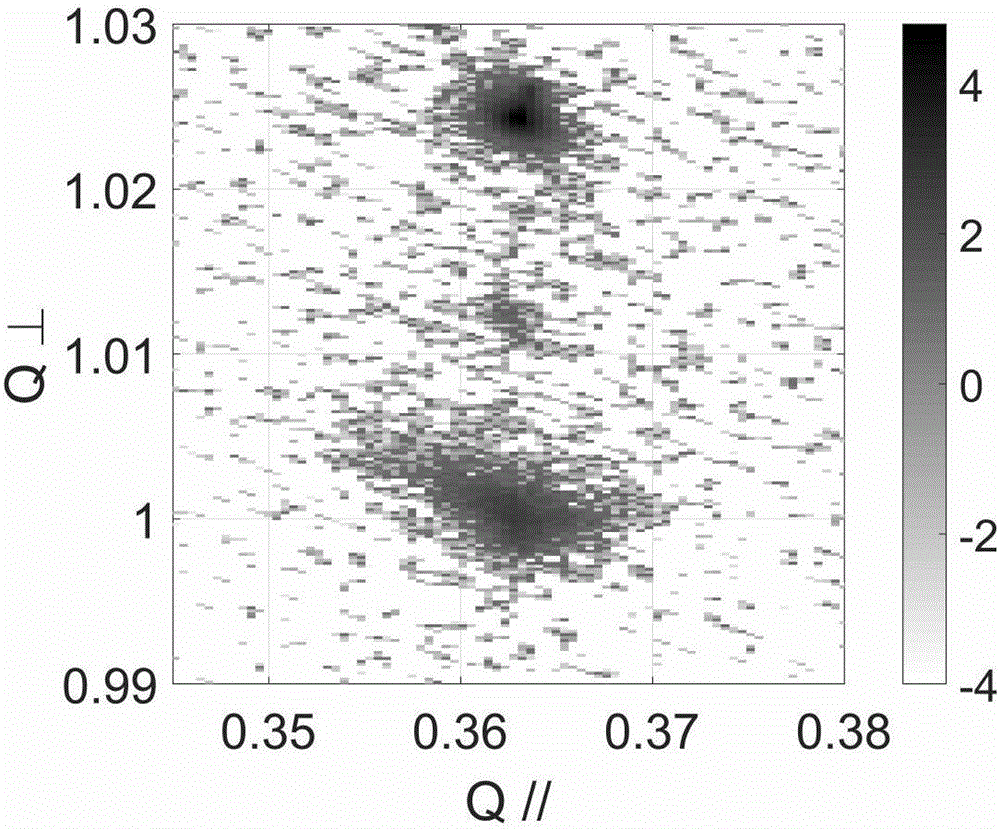

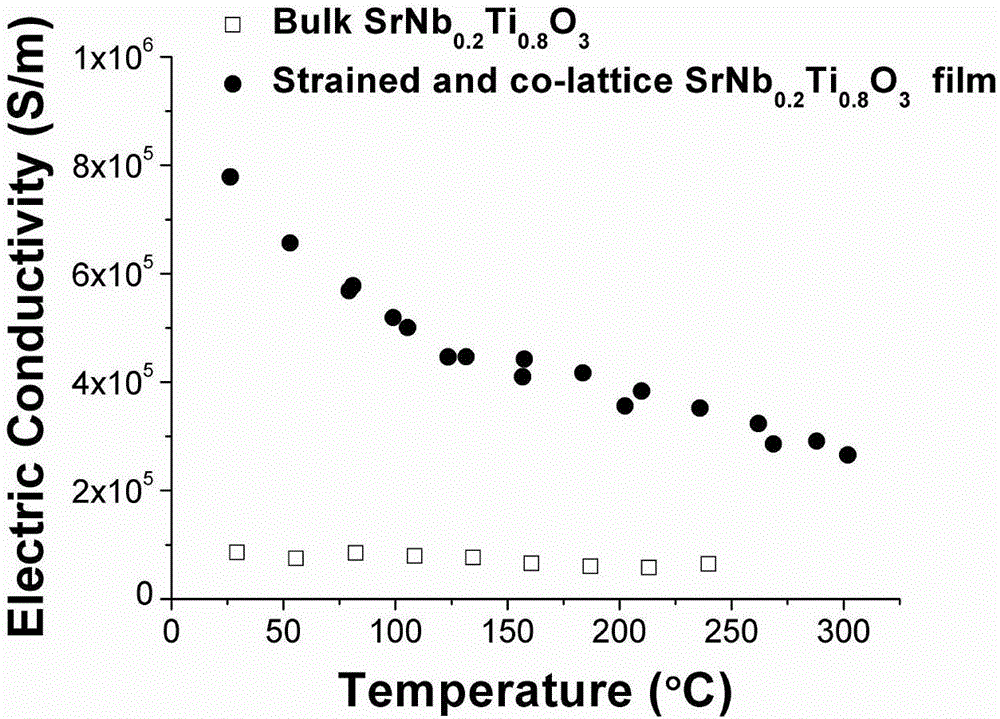

[0031] In SrTiO 3 (001) substrate, using pulsed laser deposition method in 20 Pascal argon atmosphere, substrate temperature 1000 degrees Celsius to grow 1 micron SrNb 0.2 Ti 0.8 o 3 . During the growth process, the plasma temperature was controlled at 0.1eV, the average kinetic energy of ions was 11.5eV, the ionization rate was 10%, and the distance between the substrate and the target was 10 cm. X-ray two-dimensional reciprocal space imaging shows that the film and the substrate material have the same Qx component, which indicates that the grown film and the substrate have the same in-plane lattice parameters on the growth plane (see figure 1), so the compressive stress can be maintained; due to the effect of the stress field, the electrical conductivity and the Seebeck coefficient of the film material are significantly improved compared with the same composition and thickness of the film material in the stress-free state (see image 3 , Figure 4 ). The room temperatu...

Embodiment 2

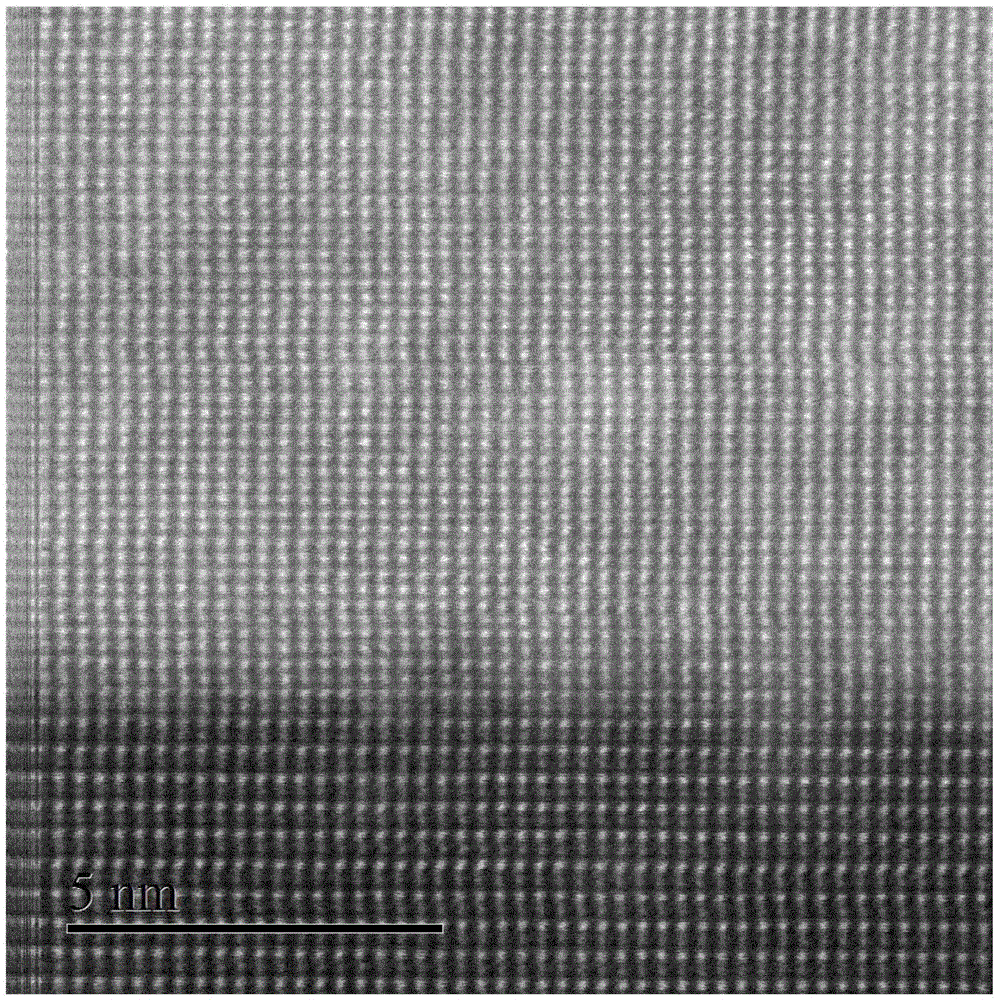

[0033] In SrTiO 3 On the (001) substrate, use the pulsed laser deposition method to grow 1 micron SrTi under the oxygen atmosphere of 20 Pascals, and the substrate temperature is 1000 degrees Celsius. 0.4 Nb 0.6 TiO 3 . During the growth process, the plasma temperature was controlled at 0.2eV, the average kinetic energy of ions was 5eV, the ionization rate was 30%, and the distance between the substrate and the target was 3 cm. It can be seen from the transmission electron microscope photos at the interface that the grown film has the same in-plane lattice parameters as the substrate on the growth plane (see figure 2 ), so the compressive stress is maintained; due to the stress field, the electrical conductivity and Seebeck coefficient of the film material are significantly improved compared with the same composition and thickness of the film material in the unstressed state. Among them, the conductivity is increased by 2 times, and the Seebeck coefficient is increased by...

Embodiment 3

[0035] In SrTiO 3 (110) On the substrate, 100 nm La 0.1 Sr 0.9 TiO 3 . During the growth process, the plasma temperature was controlled at 0.5eV, the average kinetic energy of ions was 20eV, the ionization rate was 20%, and the distance between the substrate and the target was 2 cm. Through X-ray two-dimensional reciprocal space imaging, it can be seen that the film and the substrate material have the same Qx component, so the compressive stress can be maintained; For the same composition and thickness of the film material grown, the electrical conductivity is increased by 10 times, and the Seebeck coefficient is increased by 20 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com