A separating column used for purification and copper removing

A separation column and column technology, applied in the field of separation columns, can solve the problems of separation columns without copper ions, blockage of chromatographic columns, etc., and achieve the effects of large capacity, ensuring mechanical strength, and stable chemical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

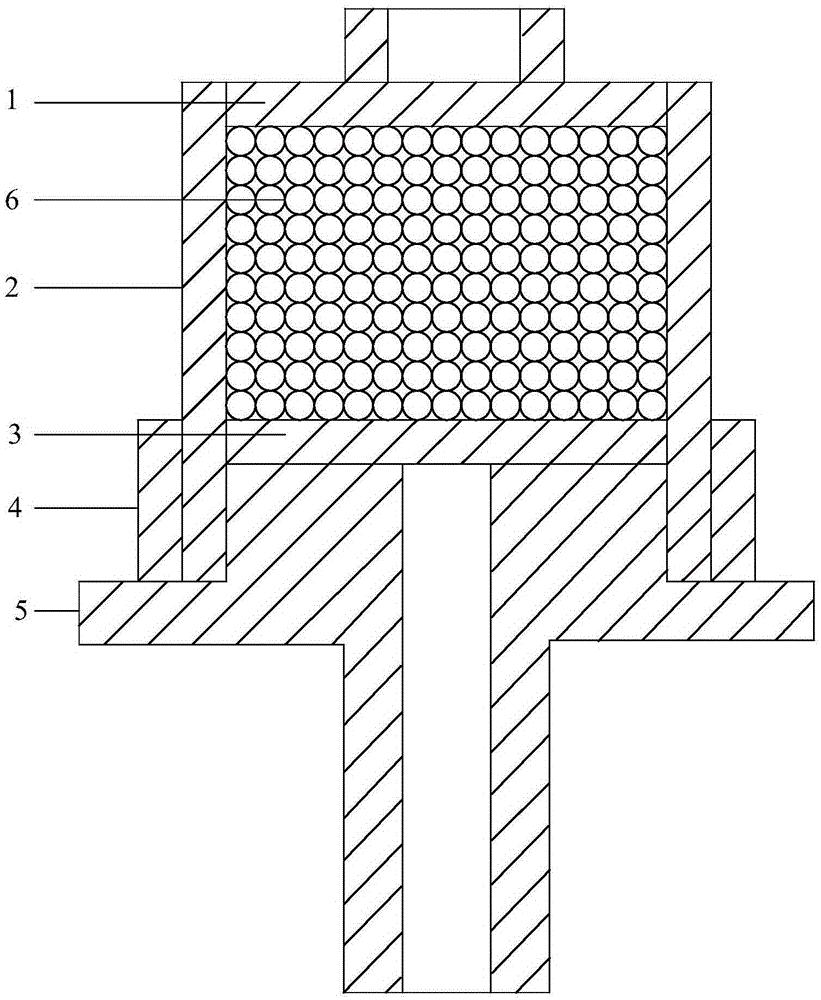

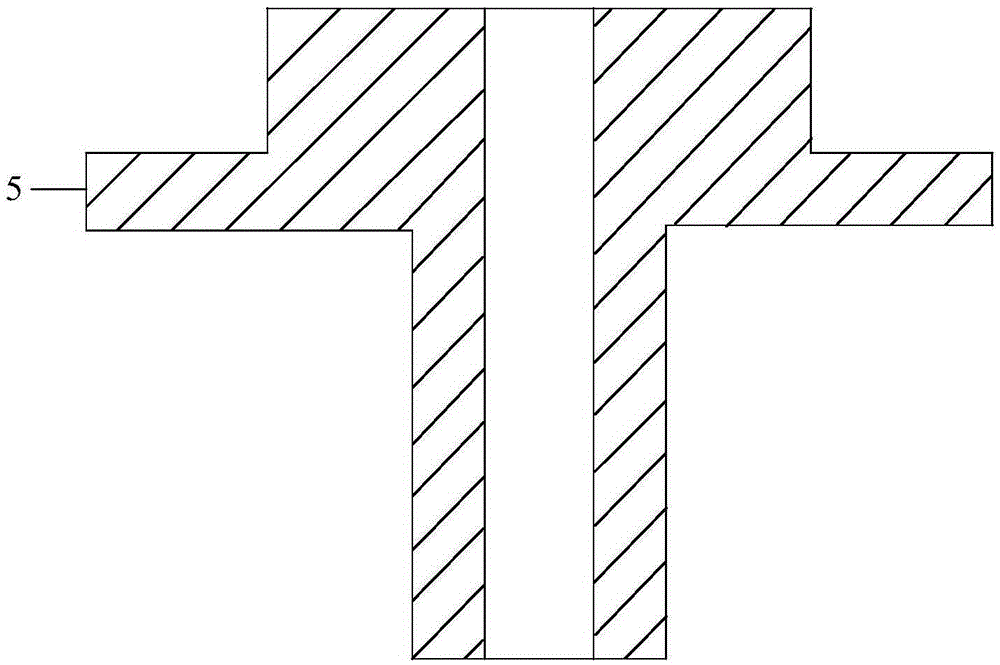

[0027] Such as figure 1 or figure 2 As shown, a separation column for purifying and removing copper includes a column body 2, a head 5 and an ion exchange resin 6. The column body 2 is a hollow cylindrical column body, and its upper end is provided with a standard interface for inserting a syringe. The upper end of the head 5 is inserted into the cavity at the lower end of the column body 2 and fixedly connected with the column body 2 , and the ion exchange resin 6 is filled into the cavity of the column body 2 . Wherein said cylinder 2 is a polytetrafluoroethylene cylinder.

[0028] The separation column also includes a detachable upper sieve plate 1 and a lower sieve plate 3 arranged in the cavity of the column body 2, the upper sieve plate 1 is in contact with the lower end surface of the standard interface, and the lower sieve plate 3 is in contact with the lower end surface of the standard interface. The sieve plate 3 is in contact with the upper surface of the head 5 ...

Embodiment 2

[0030] Such as figure 1 or figure 2 As shown, a separation column for purifying and removing copper includes a column body 2, a head 5 and an ion exchange resin 6. The column body 2 is a hollow cylindrical column body, and its upper end is provided with a standard interface for inserting a syringe. The upper end of the head 5 is inserted into the cavity at the lower end of the column body 2 and fixedly connected with the column body 2 , and the ion exchange resin 6 is filled into the cavity of the column body 2 . Wherein said cylinder 2 is a polytetrafluoroethylene cylinder.

[0031] The separation column also includes a detachable upper sieve plate 1 and a lower sieve plate 3 arranged in the cavity of the column body 2, the upper sieve plate 1 is in contact with the lower end surface of the standard interface, and the lower sieve plate 3 is in contact with the lower end surface of the standard interface. The sieve plate 3 is in contact with the upper surface of the head 5 ...

Embodiment 3

[0033] Such as figure 1 or figure 2 As shown, a separation column for purifying and removing copper includes a column body 2, a head 5 and an ion exchange resin 6. The column body 2 is a hollow cylindrical column body, and its upper end is provided with a standard interface for inserting a syringe. The upper end of the head 5 is inserted into the cavity at the lower end of the column body 2 and fixedly connected with the column body 2 , and the ion exchange resin 6 is filled into the cavity of the column body 2 . Wherein said cylinder 2 is a polytetrafluoroethylene cylinder.

[0034] The separation column also includes a detachable upper sieve plate 1 and a lower sieve plate 3 arranged in the cavity of the column body 2, the upper sieve plate 1 is in contact with the lower end surface of the standard interface, and the lower sieve plate 3 is in contact with the lower end surface of the standard interface. The sieve plate 3 is in contact with the upper surface of the head 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com