L-oxiracetam oral dispersible membrane and preparation method thereof

An oral instant film, film technology, applied in non-active ingredient medical preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve the gritty feeling and bitter taste, drug hydrolysis, solid particle coalescence Bigger and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

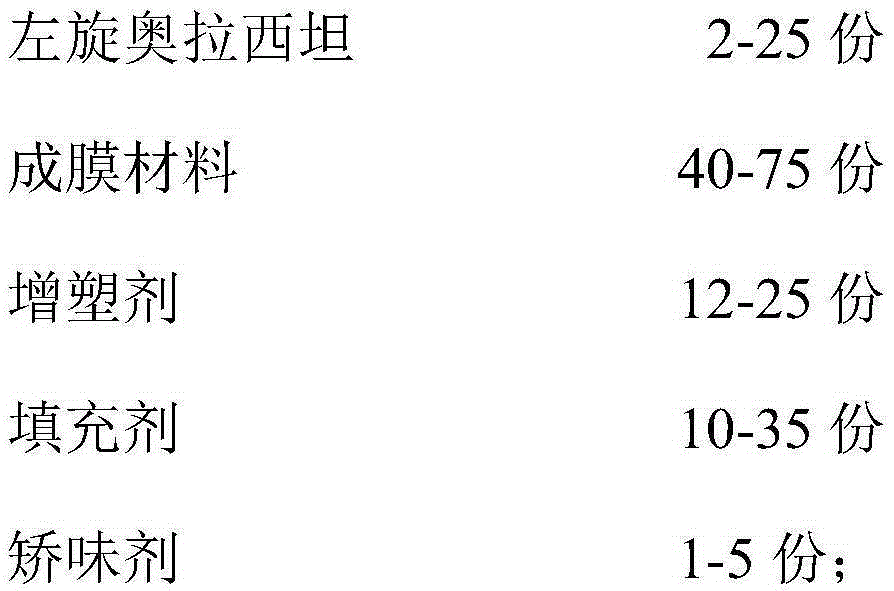

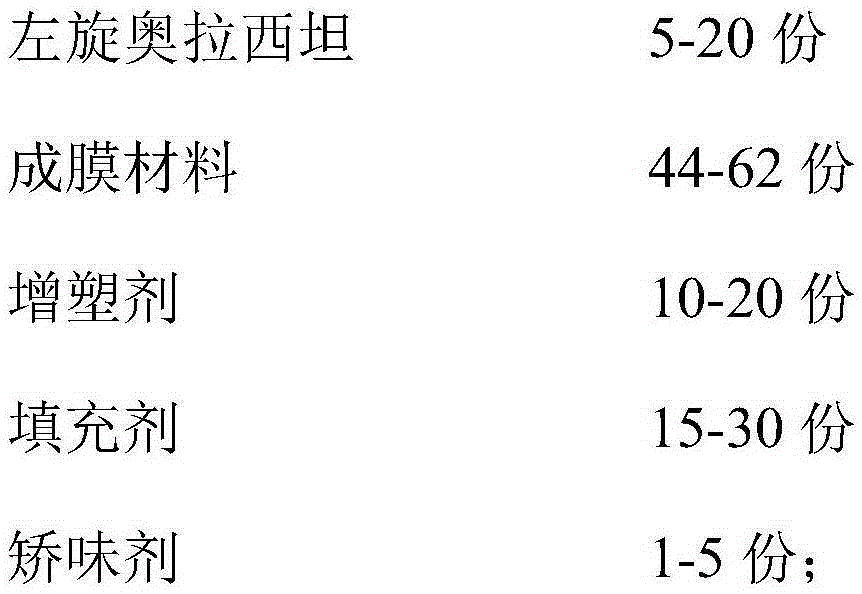

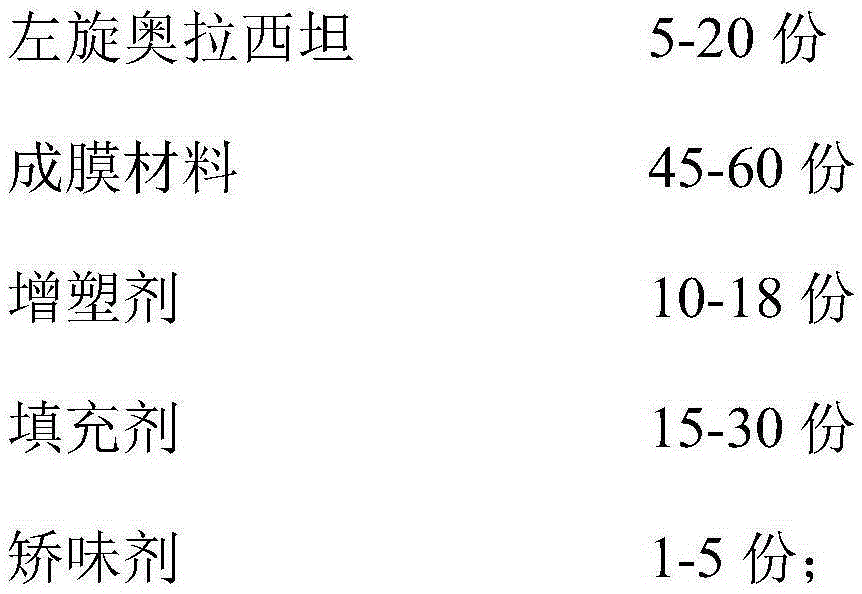

Method used

Image

Examples

Embodiment 1

[0101] The preparation of levoxiracetam film, adopts the following steps:

[0102] 1) Dissolve 58g of film-forming material (acrylic acid ester and hydroxypropyl methylcellulose, wherein the dosage of hydroxypropylmethylcellulose is 30g) with 80mL of deionized water, and remove air bubbles to obtain a uniform viscous liquid;

[0103] 2) Disperse 18g of dibutyl phthalate, 15g of microcrystalline cellulose and 2g of xylitol with 50mL of deionized water to form a dispersion;

[0104] 3) Add the dispersion of step 2) to the viscous liquid of step 1), and add 7g of levoxiracetam to disperse evenly, and then let it stand to remove air bubbles;

[0105] 4) Coat the viscous liquid after removing air bubbles with a drug film coating dryer at a coating speed of 50cm / min, then dry at 65-68°C, peel off and cut.

Embodiment 2

[0107] The preparation of levoxiracetam film, adopts the following steps:

[0108] 1) Dissolve 50g of film-forming material (acrylic acid ester and hydroxypropyl methylcellulose, wherein the dosage of hydroxypropylmethylcellulose is 10g) with 50mL of deionized water, and remove air bubbles to obtain a uniform viscous liquid;

[0109] 2) Disperse 12g triacetin, 20g low-substituted hydroxypropyl cellulose and 1g acesulfame potassium with 60mL deionized water to form a dispersion;

[0110] 3) Add the dispersion of step 2) to the viscous liquid of step 1), and add 17g of levoxiracetam to disperse evenly, then let it stand to remove air bubbles;

[0111] 4) Coat the viscous liquid after removing air bubbles with a drug film coating dryer at a coating speed of 80cm / min, then dry at 70-72°C, peel off and cut.

Embodiment 3

[0113] The preparation of levoxiracetam film, adopts the following steps:

[0114] 1) Dissolve 50g of film-forming material (acrylic acid ester and hydroxypropyl methylcellulose, wherein the dosage of hydroxypropylmethylcellulose is 20g) with 50mL of deionized water, and remove air bubbles to obtain a uniform viscous liquid;

[0115] 2) Disperse 15g of trimethyl citrate, 15g of microcrystalline cellulose and 5g of aspartame with 40mL of deionized water to form a dispersion;

[0116] 3) Add the dispersion of step 2) to the viscous liquid of step 1), and add 15g of levoxiracetam to disperse evenly, then let it stand to remove air bubbles;

[0117] 4) Coat the viscous liquid after removing air bubbles with a drug film coating dryer at a coating speed of 70cm / min, then dry at 80-85°C, peel off and cut.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| optical rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com