Method and device for producing high-purity boron tribromide

A technology of boron tribromide and a production method, which is applied to boron halide compounds, boron halides and other directions, can solve the problems of poor product quality and color, can not meet high-purity requirements, etc., and achieves the effect of smooth production process and reduced production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

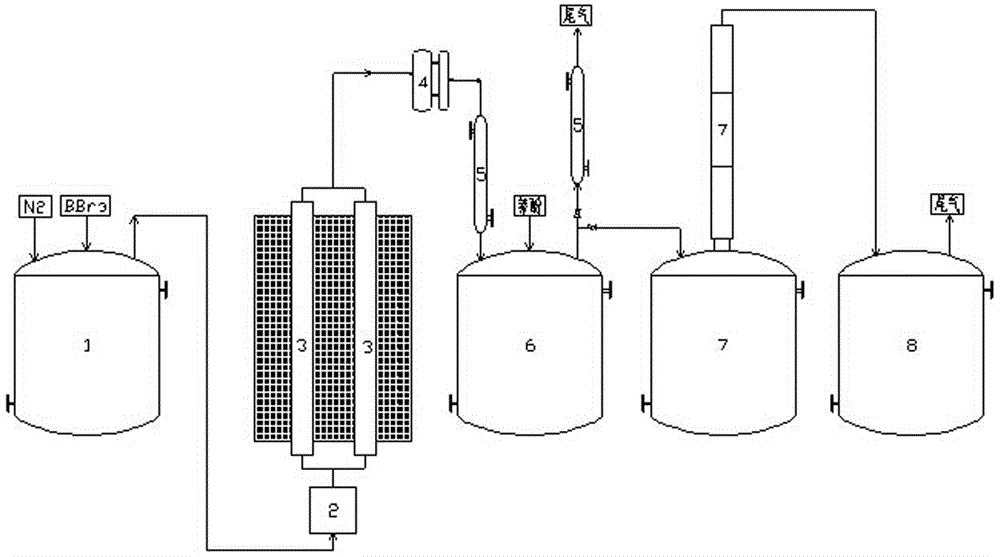

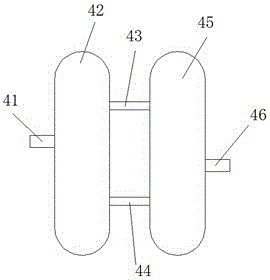

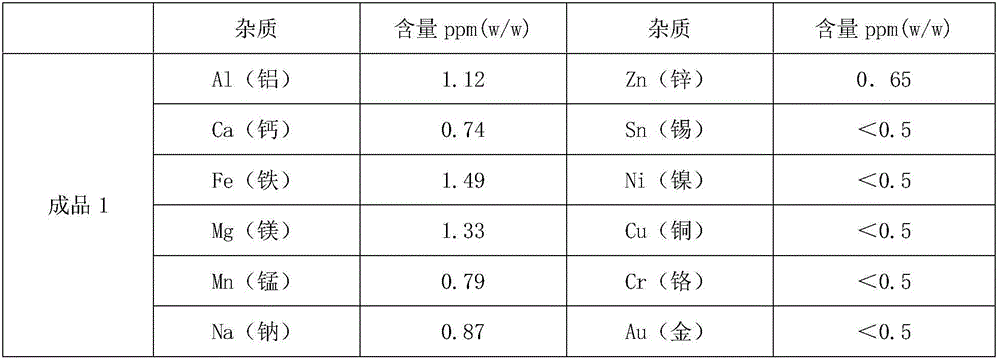

[0044] Put 12kg of industrial boron carbide with a purity of 97% and a particle size of 1 to 3 mm into multiple quartz reactors in reactor 3, with a total reaction cross-sectional area of 130 cm 2 , the temperature of the reaction furnace is raised to 650°C; 120kg of liquid bromine is put into the vaporization kettle 1 for heating and vaporization, the vaporization temperature is 120°C, and the vaporized red bromine vapor has a pressure of 0.1MPa and a flow rate of 0.4m 3 Nitrogen per hour is introduced into the drier 2 and dehydrated and dried by anhydrous calcium chloride with a particle size of 1mm and a purity of 96%, and then enters the quartz reaction furnace from the bottom of the reaction furnace 3 for bromination reaction; the tribromine produced by the reaction The boron gas comes out from the top of the reaction furnace and enters the soot trap 4; boron tribromide enters from the middle of the primary glass column 42 through the inlet 41, and the gas phase and liqu...

Embodiment 2

[0048] Put 12kg of industrial boron carbide with a purity of 97% and a particle size of 1 to 3 mm into the quartz reaction furnace of the reaction furnace 3, with a total reaction cross-sectional area of 130 cm 2 , the temperature of the reaction furnace is raised to 850°C; 120kg of liquid bromine is put into the vaporization kettle 1 to be heated and vaporized, the vaporization temperature is 120°C, and the vaporized red bromine vapor has a pressure of 0.3MPa and a flow rate of 0.8m 3 Nitrogen per hour is introduced into the drier 2 and dehydrated and dried by anhydrous calcium chloride with a particle size of 1mm and a purity of 96%, and then enters the quartz reaction furnace from the bottom of the reaction furnace 3 for bromination reaction; the tribromine produced by the reaction The boron gas comes out from the top of the reaction furnace and enters the soot trap 4; boron tribromide enters from the middle of the primary glass column 42 through the inlet 41, and the gas ...

Embodiment 3

[0052] Put 12kg of industrial boron carbide with a purity of 97% and a particle size of 1 to 3 mm into the quartz reaction furnace of the reaction furnace 3, with a total reaction cross-sectional area of 130 cm 2 , the temperature of the reaction furnace is raised to 720°C; 120kg of liquid bromine is put into the vaporization kettle 1 to be heated and vaporized, the vaporization temperature is 120°C, and the vaporized red bromine vapor has a pressure of 0.2MPa and a flow rate of 0.6m 3Nitrogen per hour is introduced into the drier 2 and dehydrated and dried by anhydrous calcium chloride with a particle size of 1mm and a purity of 96%, and then enters the quartz reaction furnace from the bottom of the reaction furnace 3 for bromination reaction; the tribromine produced by the reaction The boron gas comes out from the top of the reaction furnace and enters the soot trap 4; boron tribromide enters from the middle of the primary glass column 42 through the inlet 41, and the gas p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com