Temperature-sensitive graphene oxide and preparation method thereof

A graphene and temperature-sensitive technology, which is applied in the field of temperature-sensitive graphene oxide and its preparation, can solve the problems of temperature-sensitive materials use and weak bonding, and achieve high phase change enthalpy, good heat setting and thermal stability , the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

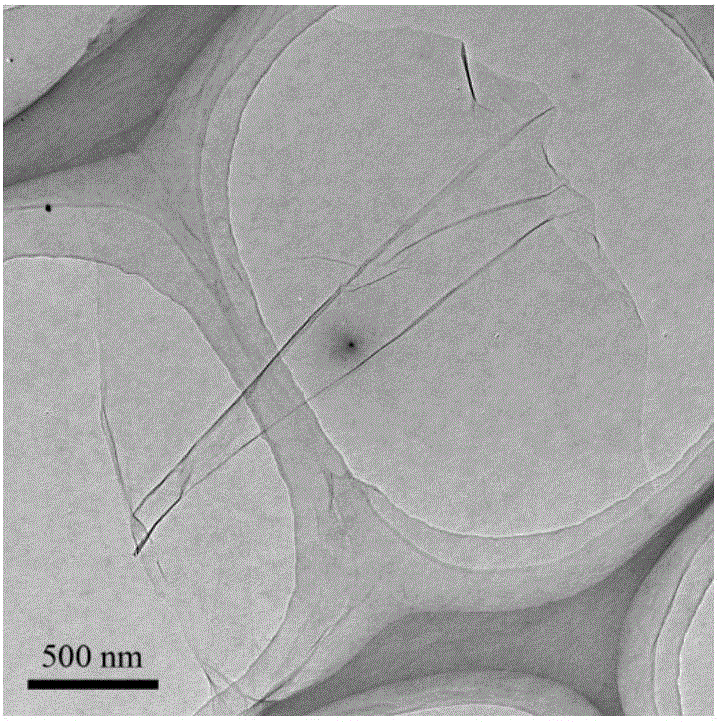

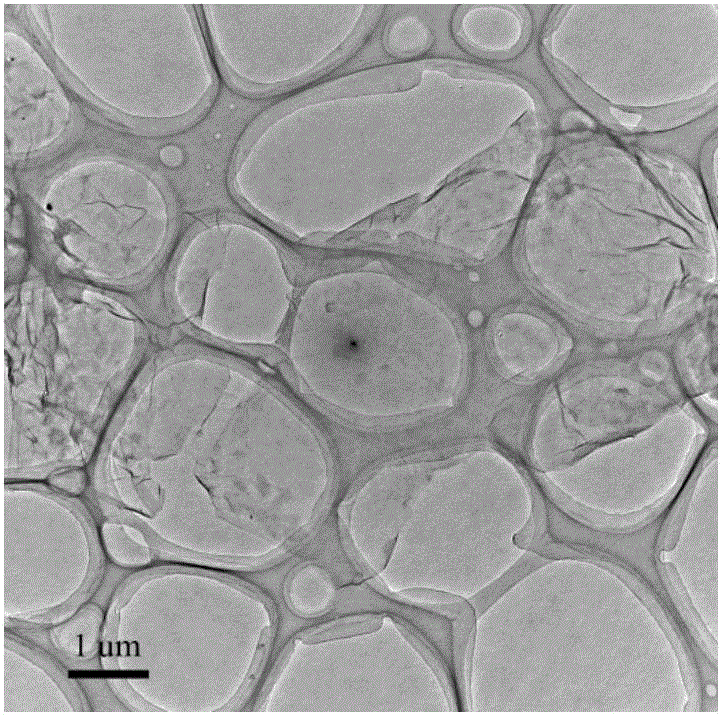

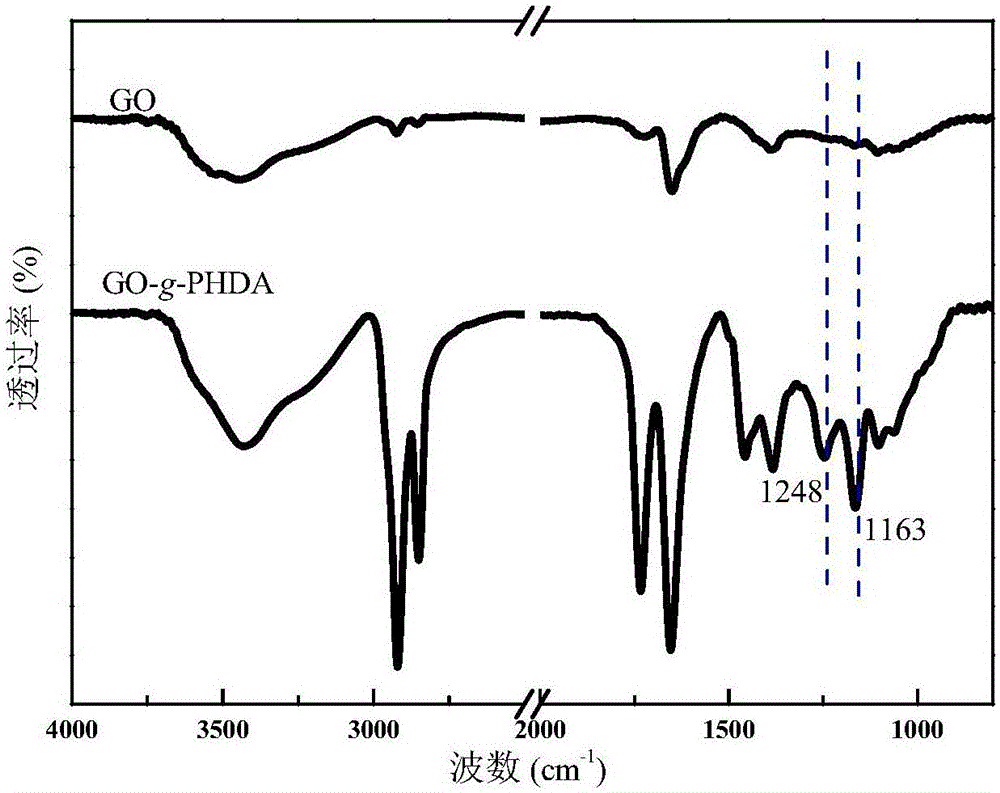

[0043] The preparation method of graphene oxide grafted n-hexadecyl acrylate thermosensitive graphene material comprises the steps:

[0044] 1) Prepare GO using the following modified Hummers method:

[0045] a) Graphite powder pre-oxidation treatment: measure 40mL of concentrated sulfuric acid in a measuring cylinder and put it into a dry three-necked flask (250mL) equipped with mechanical stirring, and heat up to 80°C; add 8.4g of potassium persulfate and 8.4g of phosphorus pentoxide, and start stirring; Weigh 10g of graphite powder into a three-necked flask, and react at 80°C for 4.5h; after the reaction, wash and filter the sample repeatedly, put it in a petri dish to dry naturally, and set aside;

[0046] b) Preparation of graphene oxide: Measure 115mL of concentrated sulfuric acid in a measuring cylinder and put it into a three-necked flask (2L) equipped with mechanical stirring, place the three-necked flask in an ice-water bath, keep the temperature of the reaction syst...

Embodiment 2

[0052] The preparation method of graphene oxide grafted n-hexadecyl methacrylate thermosensitive graphene oxide material comprises the following steps:

[0053] 1) Using commercially available few-layer graphene powder as raw material, after treating with nitric acid and hydrochloric acid (mass ratio 3:1) at 25°C for 5 hours, washing with water to prepare graphene oxide;

[0054] 2) Weigh 50 mg of the graphene oxide prepared in step 1), and ultrasonically disperse it in 100 mL of toluene. The above dispersion was added into a 250mL three-necked flask, and 100mmol of hexadecyl methacrylate (inhibitor removal agent) was added at the same time, and nitrogen gas was passed for 1h to remove oxygen in the reaction system. Then, the toluene solution of the initiator BPO was added dropwise into the three-necked flask, wherein the amount of BPO was 0.08% of the amount of monomer cetyl methacrylate. Afterwards, the temperature of the reaction system was raised to 65° C., and the reacti...

Embodiment 3

[0059] The preparation method of graphene oxide grafted n-pentacyl acrylate thermosensitive graphene oxide material comprises the following steps:

[0060] 1) Utilize above-mentioned improved Hummers method to prepare graphene oxide;

[0061] 2) Weigh 150 mg of the graphene oxide prepared in step 1), and ultrasonically disperse it in 100 mL of DMF. The above dispersion liquid was added into a 250 mL three-necked flask, and 100 mmol n-pentacyl acrylate monomer (inhibitor removal agent) (0.19%) was added at the same time, and nitrogen gas was passed for 1 hour to remove oxygen in the reaction system. Then, the DMF solution of the initiator AIBN was added dropwise into the three-necked flask, and the amount of the initiator AIBN was 0.05% of the amount of the n-pentadecyl acrylate monomer. Afterwards, the temperature of the reaction system was raised to 70° C., and the reaction was carried out for 48 hours under stirring conditions to obtain a reaction mixture.

[0062] 3) Prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com