Refining method of low-odor and high-activity polyether polyol

A high-activity polyether and polyether polyol technology, which is applied in the field of polyether polyol, can solve the problems of prolonging the reaction cycle, increasing the purchase cost, and prolonging the production cycle, so as to reduce the content of aldehydes, shorten the processing time, Effect of reducing product odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

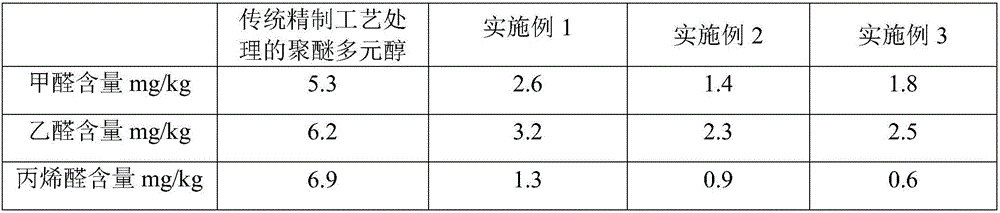

Examples

Embodiment 1

[0020] Add 36.8g of glycerin and 3.76g of KOH into a 2.5L autoclave at room temperature, raise the temperature to 110°C, vacuum dehydrate for 4 hours, slowly add 1468g of propylene oxide, control the reaction temperature at 110-115°C, and the reaction pressure is less than 0.20MPa, and carry out polymerization Reaction, then fill nitrogen to 0.30MPa, internal pressure reaction for 3h, then slowly add 376g of ethylene oxide, control reaction temperature 110-115°C, reaction pressure less than 0.20MPa, carry out polymerization reaction, then fill nitrogen to 0.30MPa, internal pressure React for 1 h, then vacuum degassing for 1 h to obtain 1880 g of highly active crude polyether polyol.

[0021] Transfer the high-activity crude polyether polyol obtained above to a refining treatment tank, stir and control the temperature to 80°C, add 18.8g of water, keep stirring at 80°C for 0.5h, then add 18.8g of acid magnesium silicate, and use nitrogen to Pressurize to 0.1MPa, keep stirring at...

Embodiment 2

[0023] Add 36.8g of glycerin and 6.6g of KOH into a 2.5L autoclave at room temperature, raise the temperature to 110°C, vacuum dehydrate for 5 hours, slowly add 1767.2g of propylene oxide, control the reaction temperature at 110-115°C, and the reaction pressure is less than 0.20MPa. Polymerization reaction, then fill nitrogen to 0.30MPa, internal pressure reaction for 3h, then slowly add 396g of ethylene oxide, control reaction temperature 110-115°C, reaction pressure is less than 0.20MPa, carry out polymerization reaction, then fill nitrogen to 0.30MPa, internal Pressure reaction for 1 h, and then vacuum degassing for 1 h to obtain 2200 g of highly active crude polyether polyol.

[0024] Transfer the high-activity crude polyether polyol obtained above to a refining treatment tank, stir and control the temperature to 90°C, add 88g of water, keep stirring at 90°C for 1 hour, raise the temperature to 100°C, add 44g of acid magnesium silicate, and use Nitrogen press to 0.2MPa, ke...

Embodiment 3

[0026] Add 30.7g of glycerin and 4.69g of KOH into a 2.5L autoclave at room temperature, raise the temperature to 110°C, vacuum dehydrate for 6 hours, slowly add 1782.7g of propylene oxide, control the reaction temperature at 110-115°C, and the reaction pressure is less than 0.20MPa, and carry out Polymerization reaction, then fill nitrogen to 0.30MPa, internal pressure reaction for 3h, then slowly add 320g of ethylene oxide, control reaction temperature 110-115°C, reaction pressure is less than 0.20MPa, carry out polymerization reaction, then fill nitrogen to 0.30MPa, internal Pressure reaction for 1 h, followed by vacuum degassing for 1 h to obtain 2130 g of highly active crude polyether polyol.

[0027] Transfer the high-activity crude polyether polyol obtained above to a refining treatment tank, stir and control the temperature to 70°C, add 54g of water, keep stirring at 70°C for 1 hour, then raise the temperature to 110°C, add 32g of acid magnesium silicate, Stamp it with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com