Monoprotic peroxyacetic acid solid granular disinfectant

A monobasic peracetic acid solid, peracetic acid technology, applied in the directions of disinfectants, biocides, animal repellents, etc., can solve the problems of limited use, high metal corrosion, slow production speed, etc., and achieve safe use. Reliable, low water temperature requirements, fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

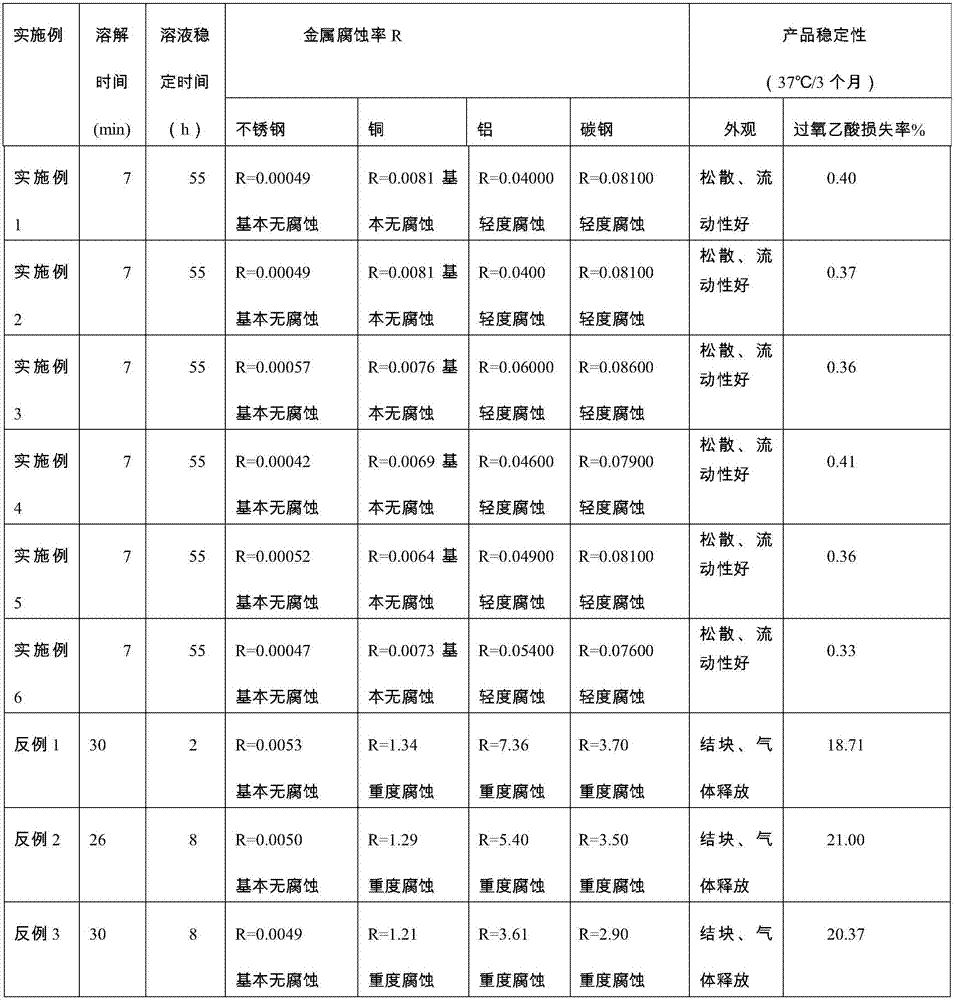

Examples

Embodiment 1

[0044] First, tetraacetylethylenediamine 5g, sodium dodecylbenzenesulfonate 0.6g, tartaric acid 3.0g, sodium hexametaphosphate 1.0g, hydroxyethylidene diphosphate 0.6g, benzotriazole 0.2g and brilliant blue 0.005 g Mixed and granulated into granules of different specifications, and then fully mixed with 10g of sodium percarbonate granules.

Embodiment 2

[0046] First, 5g of tetraacetylethylenediamine, 0.6g of sodium dodecylbenzenesulfonate, 3.0g of citric acid, 1.0g of sodium hexametaphosphate, 0.6g of hydroxyethylidene diphosphate, 0.2g of benzotriazole and brilliant blue 0.005g was mixed and granulated into granules of different specifications, and then fully mixed with 10g of sodium percarbonate granules.

Embodiment 3

[0048] First, tetraacetylethylenediamine 5g, fatty alkyl polyethylene glycol ether 0.5g, tartaric acid 3.0g, sodium hexametaphosphate 1.0g, hydroxyethylidene diphosphate 0.6g, benzotriazole 0.2g and brilliant blue 0.005 g Mixed and granulated into granules of different specifications, and then fully mixed with 10g of sodium percarbonate granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com