Anti-pollution composite graphene oxide nanofiltration membrane and production method thereof

A composite oxidation and graphene membrane technology, applied in the field of nanofiltration membranes, can solve problems such as poor stability and integrity, and easy damage of graphene oxide membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] Correspondingly, the embodiment of the present invention also provides a method for preparing an anti-pollution composite graphene oxide nanofiltration membrane, which can be used to prepare the above-mentioned nanofiltration membrane, which includes the following steps:

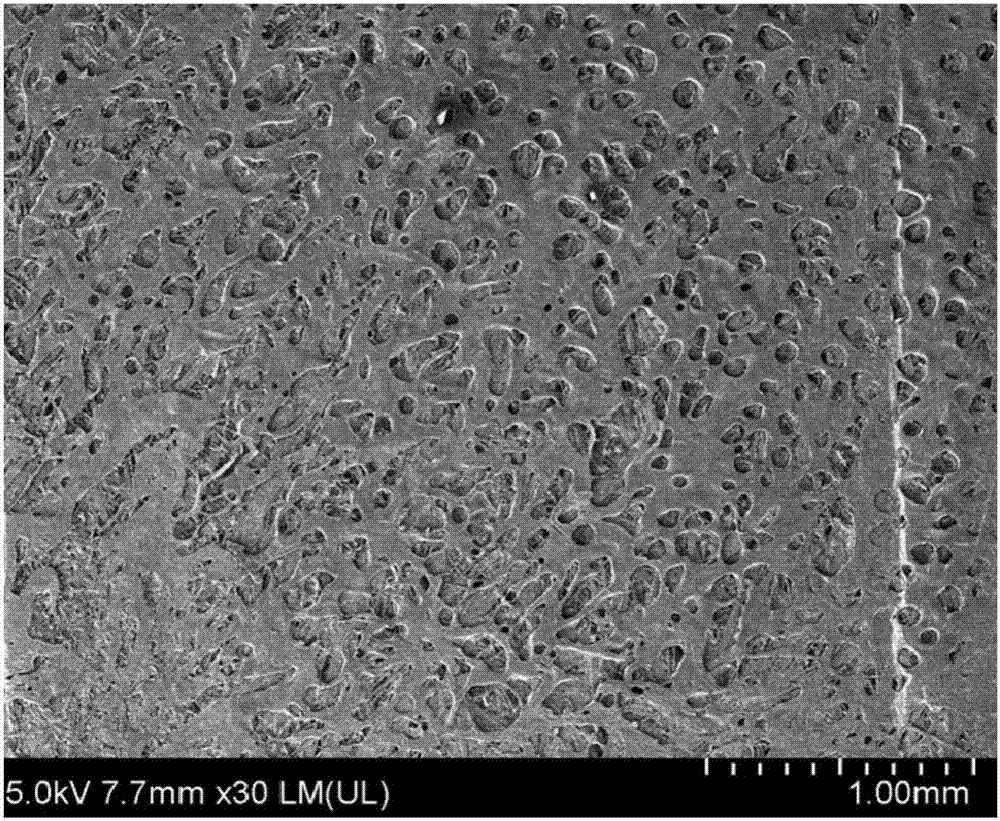

[0024] S01, using the immersion precipitation phase inversion method to prepare the above-mentioned basement film;

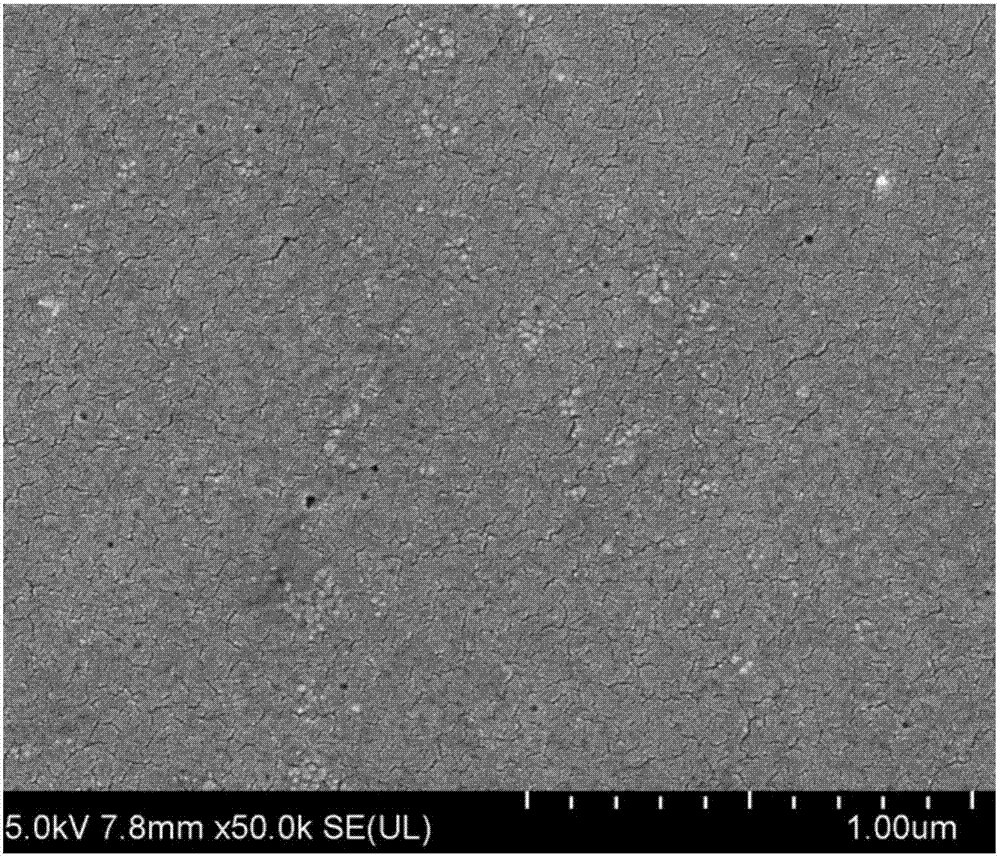

[0025] S02, preparing the above-mentioned graphene oxide film on the base film;

[0026] S03. On the graphene oxide film, polyvinyl alcohol is cross-linked with the above-mentioned cross-linking agent to form a cross-linked film with a porous structure that does not affect the function of the graphene oxide film, wherein the cross-linking agent is a binary aldehyde or horseradish to acid anhydride.

[0027] Specifically, in the step S01, the base film may be prepared using existing technologies. The base film material can be selected from conventional polymers, preferably the above-me...

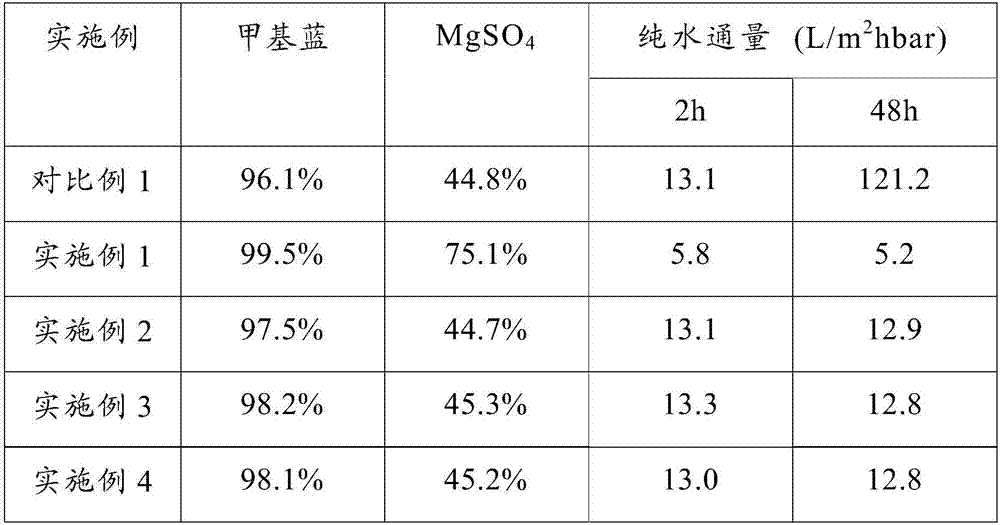

Embodiment 1

[0060] (1) Graphene oxide aqueous solution is prepared by Hummers method

[0061] Put flake graphite as raw material in a container, add concentrated sulfuric acid with a mass fraction of 98%, keep the temperature of the mixture at 0°C in an ice-water bath, then add potassium permanganate, and stir evenly at a temperature lower than 20°C. Add 50.0ml of concentrated sulfuric acid to every 1.0g of graphite flakes, the quality of potassium permanganate is 4 times that of graphite flakes, and place it in a constant temperature water bath to heat up to 35°C and keep it for 1.5h; Dilute with water, heat up to 90°C in a constant temperature water bath, keep it for 30 minutes, then add hydrogen peroxide solution with a mass fraction of 30%, cool to room temperature, the solution changes from brown to khaki, where concentrated sulfuric acid: ultrapure water: hydrogen peroxide The volume ratio is 50:100:10.

[0062] Filter the above solution to obtain a brown paste colloid, wash the co...

Embodiment 2

[0070] (1) Graphene oxide aqueous solution is obtained by the Hummers method.

[0071] Put flake graphite as raw material in a container, add concentrated sulfuric acid with a mass fraction of 98%, keep the temperature of the mixture at 0°C in an ice-water bath, then add potassium permanganate, and stir evenly at a temperature lower than 20°C. Add 50.0ml of concentrated sulfuric acid to every 1.0g of graphite flakes, the quality of potassium permanganate is 4 times that of graphite flakes, and place it in a constant temperature water bath to heat up to 35°C and keep it for 1.5h; Dilute with water, heat up to 90°C in a constant temperature water bath, keep it for 30 minutes, then add hydrogen peroxide solution with a mass fraction of 30%, cool to room temperature, the solution changes from brown to khaki, where concentrated sulfuric acid: ultrapure water: hydrogen peroxide The volume ratio is 50:100:10.

[0072]Filter the above solution to obtain a brown paste colloid, wash th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com