Novel ferroferric oxide nano-particle and silicon oxide nano-fiber compounded Fenton-like catalyst and preparation method thereof

A technology of ferroferric oxide and nanofibers, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of strong hydrophobicity, chemical stability and thermal Poor stability, poor dispersibility and other problems, to achieve the effect of improving dispersibility, strong thermal and chemical stability, and enhanced firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

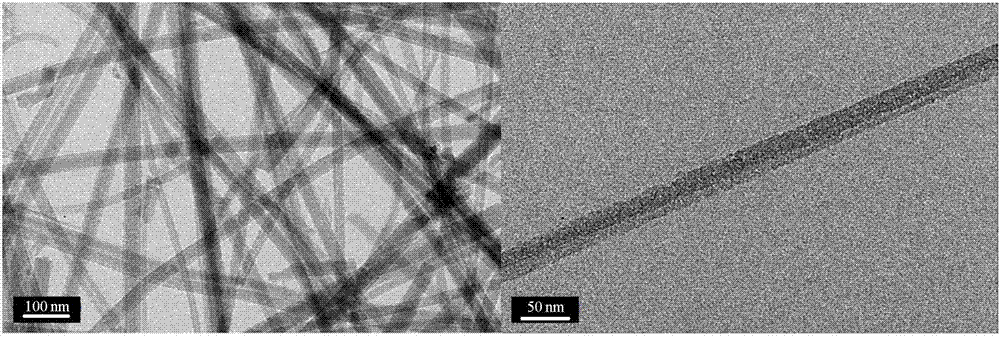

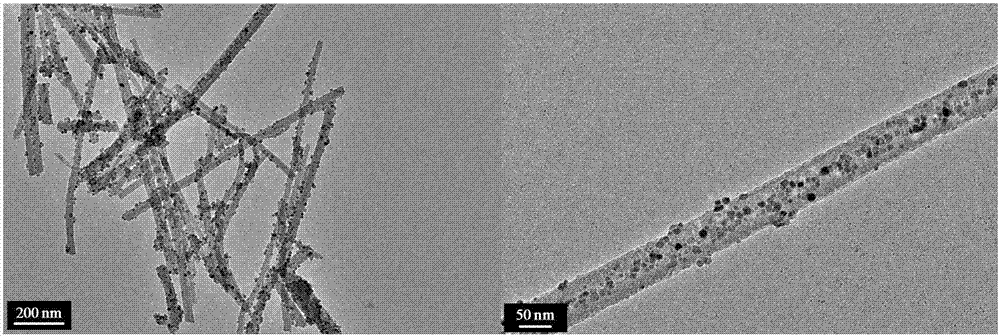

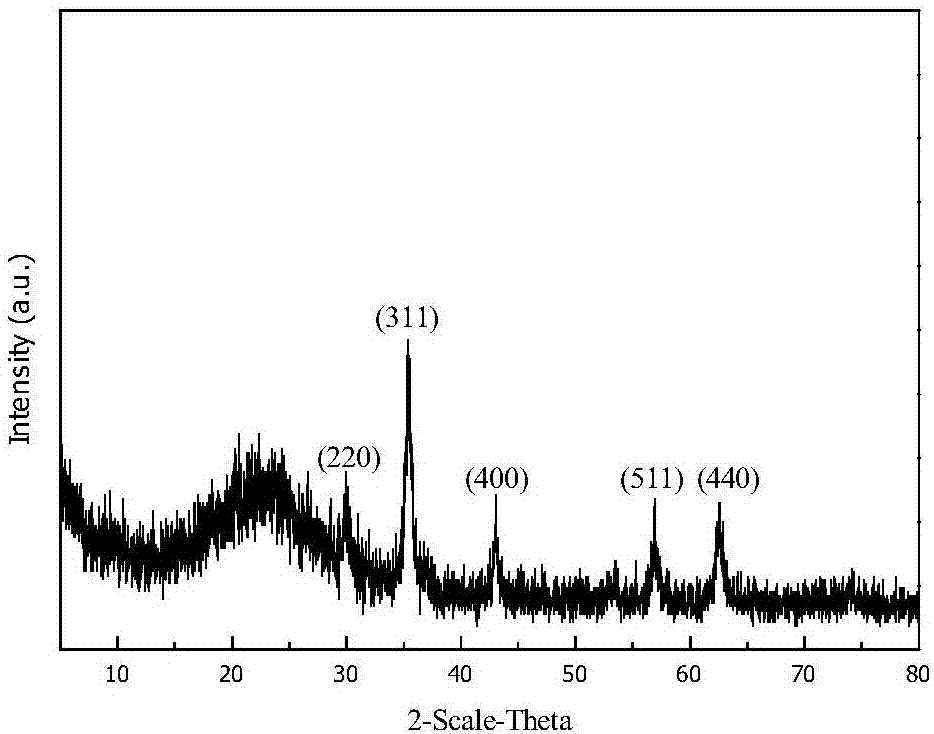

[0033] Weigh silicon oxide nanofibers (see the transmission electron microscope photo for the figure 1 ), the nanofibers have a diameter of 30-60 nm and a length of 5-20 μm. Silica nanofibers were completely dispersed in triethylene glycol at room temperature to form a homogeneous primary suspension. Weigh iron acetylacetonate, the mass ratio of iron acetylacetonate to silicon oxide nanofibers is 1:1, add iron acetylacetonate to the above primary suspension under vigorous stirring, and stir for 30 min. Under normal pressure, the suspension was heated to 195 °C at a rate of 3 °C / min in an argon protective atmosphere and kept for 15 min. Subsequently, under the same protective atmosphere conditions, the suspension was further heated to 285 °C at a rate of 8 °C / min, and then naturally cooled to room temperature after being kept warm for 30 min. After the suspension was separated from solid and liquid, it was washed three times with deionized water, and dried in an electric dryi...

Embodiment 2

[0035] Weigh silicon oxide nanofibers, the nanofibers have a diameter of 20-50 nm and a length of 1-10 μm. Silica nanofibers were completely dispersed in triethylene glycol at room temperature to form a homogeneous primary suspension. Weigh iron acetylacetonate, the mass ratio of iron acetylacetonate to silicon oxide nanofibers is 2:1, add iron acetylacetonate to the above primary suspension under vigorous stirring, and stir for 30 min. Under normal pressure, the suspension was heated to 190 °C at a rate of 3 °C / min in an argon protective atmosphere and kept for 10 min. Subsequently, under the same protective atmosphere conditions, the suspension was further heated to 280 °C at a rate of 10 °C / min, and then naturally cooled to room temperature after being kept warm for 35 min. After the suspension was separated from solid and liquid, it was washed three times with deionized water, and dried in an electric drying oven at 60 °C to constant weight. The dried product was calcine...

Embodiment 3

[0037] Weigh the silica nanofibers, the nanofibers have a diameter of 50-90 nm and a length of 2-15 μm. Silica nanofibers were completely dispersed in octadecene at room temperature to form a homogeneous primary suspension. Weigh iron acetylacetonate, the mass ratio of iron acetylacetonate to silicon oxide nanofibers is 3:1, add iron acetylacetonate to the above primary suspension under vigorous stirring conditions, and stir for 40 min. Under normal pressure, the suspension was heated to 200 °C at a rate of 3 °C / min in a nitrogen atmosphere and kept for 8 min. Subsequently, under the same protective atmosphere conditions, the suspension was further heated to 275 °C at a rate of 6 °C / min, and then naturally cooled to room temperature after being kept warm for 30 min. After the suspension was separated from solid and liquid, it was washed three times with deionized water, and dried in an electric drying oven at 60 °C to constant weight. The dried product was calcined at 450 °C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com