Hollow urchin-like phosphide material and preparation method

A sea urchin-like, phosphide technology, applied in the field of synthesis of new catalytic materials, can solve the problems of difficult operation, white phosphorus is highly toxic, flammable and explosive, etc., to reduce the risk, the preparation method is simple and easy, and the conditions are easy to control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Hollow sea urchin Ni 2 Preparation of P:

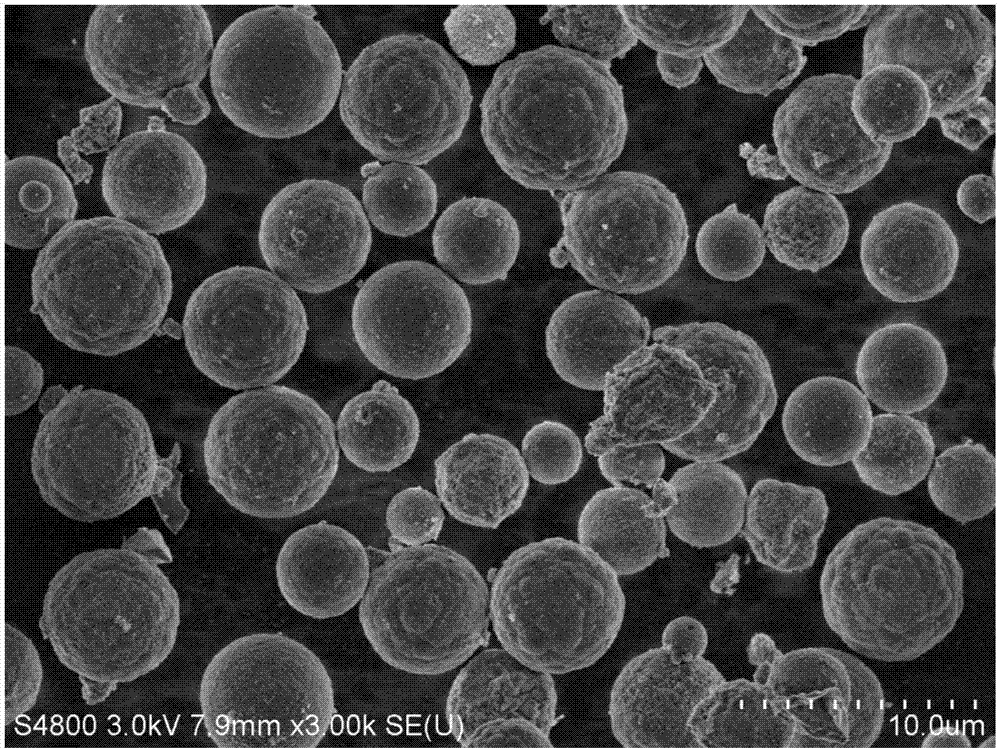

[0038] Step 1, prepare Ni simple substance: 0.713gNiCl 2 ·6H 2 0.0.2g polyvinylpyrrolidone (PVP) and 1mL hydrazine hydrate (mass percentage is 80%) are dissolved in 30mL ethylene glycol, magnetic stirring is until mixed evenly, and the mixed solution obtained is transferred in the hydrothermal reaction kettle, in Treat at 170°C for 6h. The obtained gray precipitate was centrifuged and washed several times with absolute ethanol and distilled water, and dried in a vacuum oven at 60° C. for 6 hours to obtain gray Ni powder with a diameter of 1-5 μm.

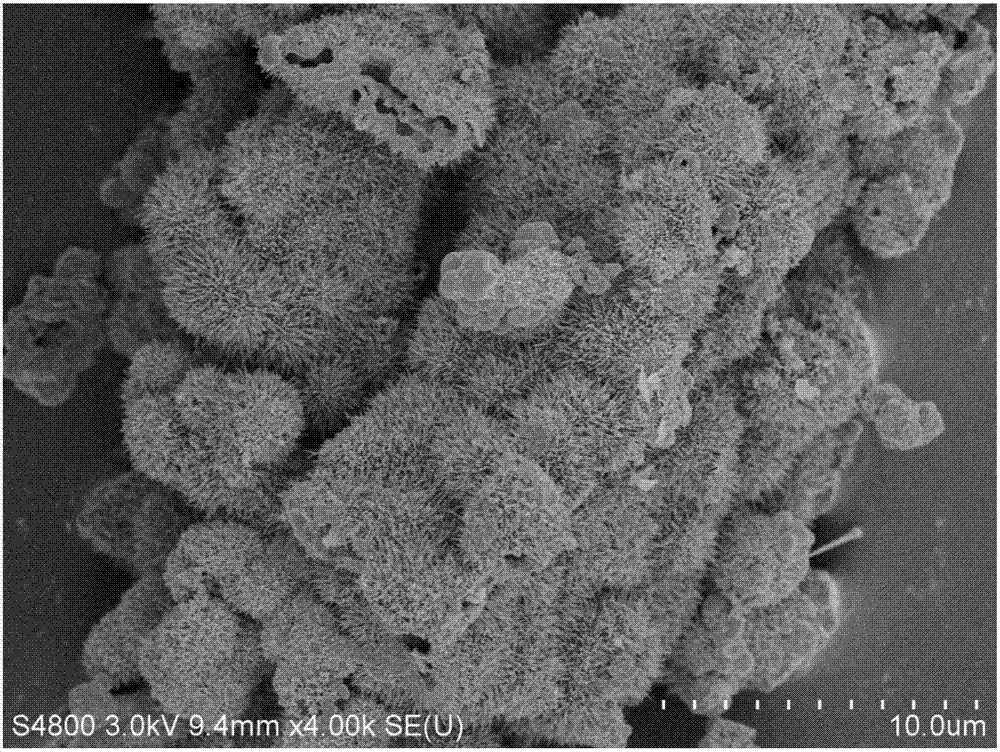

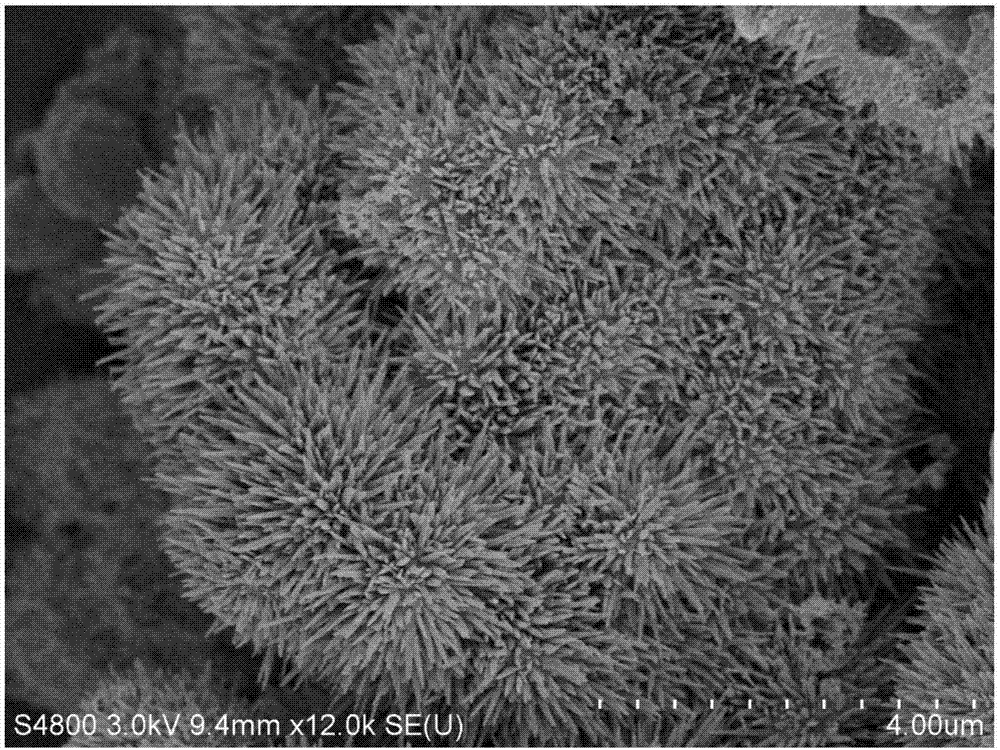

[0039] Step 2, preparing hollow sea urchin-like Ni 2 P: Disperse 0.379g of Ni elemental substance prepared in step 1 in a mixed solvent consisting of 20mL of absolute ethanol and 10mL of distilled water, and form a mixed solution under ultrasonic treatment. The resulting mixed solution was transferred to a hydrothermal reaction kettle, and 0.1 g of red phosphorus was added. Wil...

Embodiment 2

[0042] Hollow sea urchin Ni 2 Preparation of P:

[0043] In Example 1, the hydrothermal treatment temperature in step 1 was changed to 100°C, and the hydrothermal treatment time was changed to 2h; the hydrothermal treatment temperature in step 2 was changed to 100°C, and the hydrothermal treatment time was changed to 2h, and the obtained product was a hollow sea urchin with uneven appearance. Ni 2 P, the particle size is 1-5um, and the wall thickness is 0.5-1um.

Embodiment 3

[0045] Hollow sea urchin Ni 2 Preparation of P:

[0046] In Example 1, the hydrothermal treatment temperature in step 1 was changed to 220°C, and the hydrothermal treatment time was changed to 16h; the hydrothermal treatment temperature in step 2 was changed to 220°C, and the hydrothermal treatment time was changed to 20h, and the obtained product was hollow sea urchin-like Ni 2 P, the particle size is 1-5um, and the wall thickness is 0.5-1um.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com