Electrolysis electrosparking method using planar thin metal sheet electrode

A technology of planar electrodes and processing methods, which is applied in the field of micromachining and can solve problems such as the inability to fully meet the needs of electrolytic sparks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

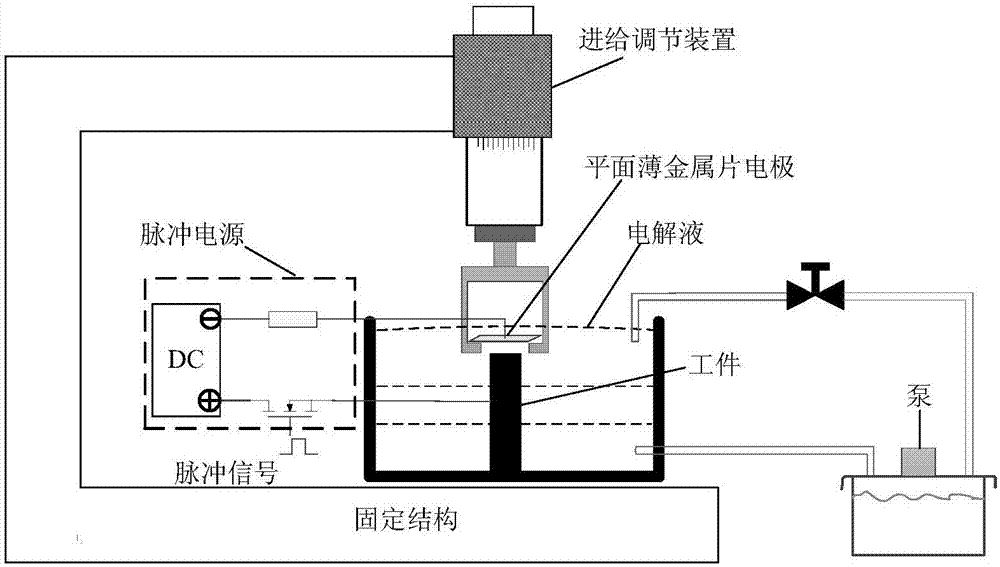

[0029] An electrolytic spark discharge machining device using a flat thin metal sheet electrode, comprising: a fixed structure, a feed adjustment device, a pulse power supply, a flat thin metal sheet electrode, a workpiece, and a solution tank, the feed adjustment device is fixed on the fixed structure, The flat thin metal sheet electrode is installed under the feed adjustment device, and the workpiece is installed in the solution tank under the flat thin metal sheet electrode. The feed adjustment device is driven by a servo motor, and the macro feed of the vertical position of the electrode can be realized through program control. The distance between the thin metal sheet and the workpiece is 5μm-50μm; the thin metal sheet and the workpiece form a capacitor C, and the thin metal sheet and the workpiece are the two poles of the capacitor C, and the two poles are respectively connected to the pulse power supply to form an electrolytic cell. The pulse power supply voltage is about...

Embodiment 2

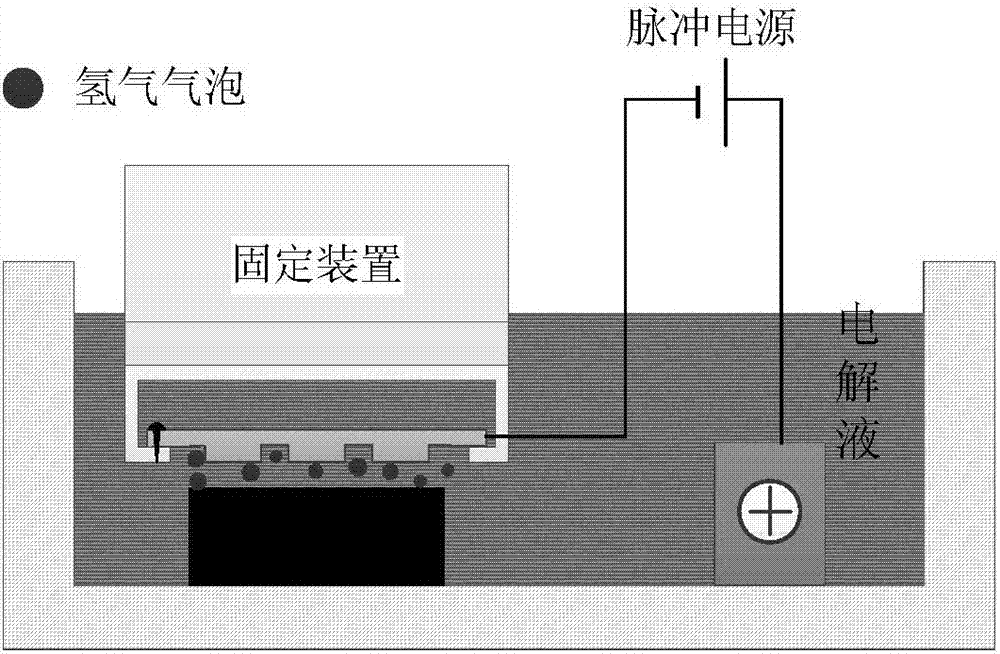

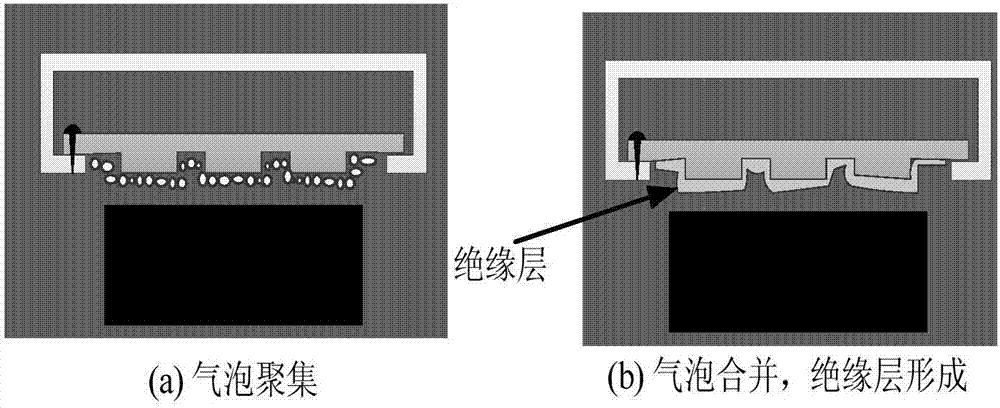

[0033] Adopt the processing method of embodiment 1 processing device, preferred step (1) electrolytic reaction stage, as figure 2 As shown, it includes, feeding close to the workpiece through the adjusting device, immersing the plane thin metal sheet electrode (tool) electrode in the electrolyte, and the tool electrode is connected to the negative pole of the pulse power supply as the cathode of the electrolytic reaction. The positive electrode of the pulse power supply is connected to the workpiece as the anode of the electrolytic reaction. After the pulse power supply is energized, a potential difference is generated between the tool electrode and the auxiliary electrode, and the positive ions in the electrolyte move to the tool electrode (cathode), and the negative ions move to the workpiece (anode). , so that a chemical reaction occurs in the electrolyte. Hydrogen gas bubbles begin to be generated around the flat thin metal sheet (cathode) as the tool electrode, and the g...

Embodiment 3

[0039] As a preferred solution of the processing method in Example 2, the present invention first processes a micro electrode on a flat thin metal sheet by micro electric discharge machining or fused deposition molding method, and adopts a metal bridge structure of a curved cantilever to be installed under the feeding device , the designed feeding device realizes the macro-feeding movement of the electrode position through motor adjustment. The pulse signal is used to control the MOSFET switch to control the charge between the flat thin metal sheet electrode and the workpiece, and the electrostatic force is used to make the metal bridge structure with curved cantilever connected to the metal sheet deform and displace, so as to realize the micro-feed of the vertical position of the electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com