Preparation method of sleeve-fish bone nanofiber

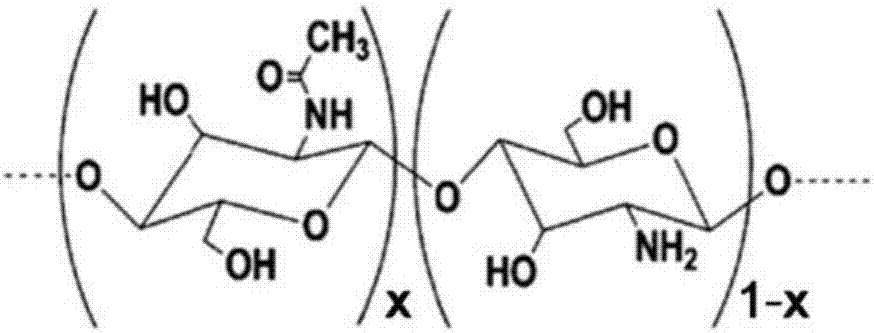

A nanofiber, squid technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of unable to prepare nanofibers, unable to prepare nanofibers, etc., and achieve the effect of broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

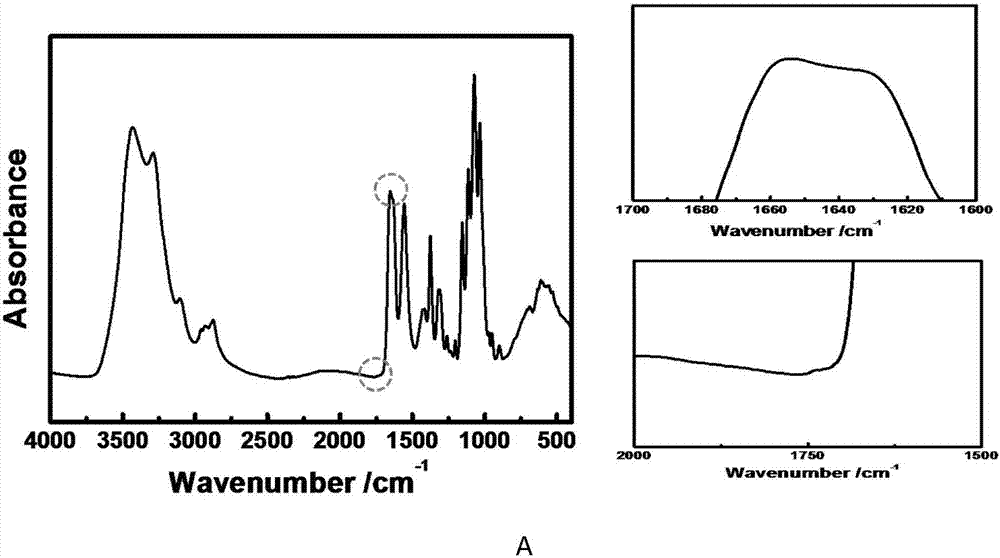

[0039] 1 gram of squid bone was added to 100 ml of 10wt% ammonium persulfate solution, stirred and heated at 40°C for 72 hours to obtain a chitin flocculent reactant, washed to neutrality, and prepared a 0.1wt% aqueous dispersion The pH is adjusted to 9,300W for 15 minutes with sodium hydroxide with a mass fraction of 4wt% to obtain a translucent aqueous dispersion of β-crystalline chitin nanofibers with carboxyl groups.

Embodiment 2

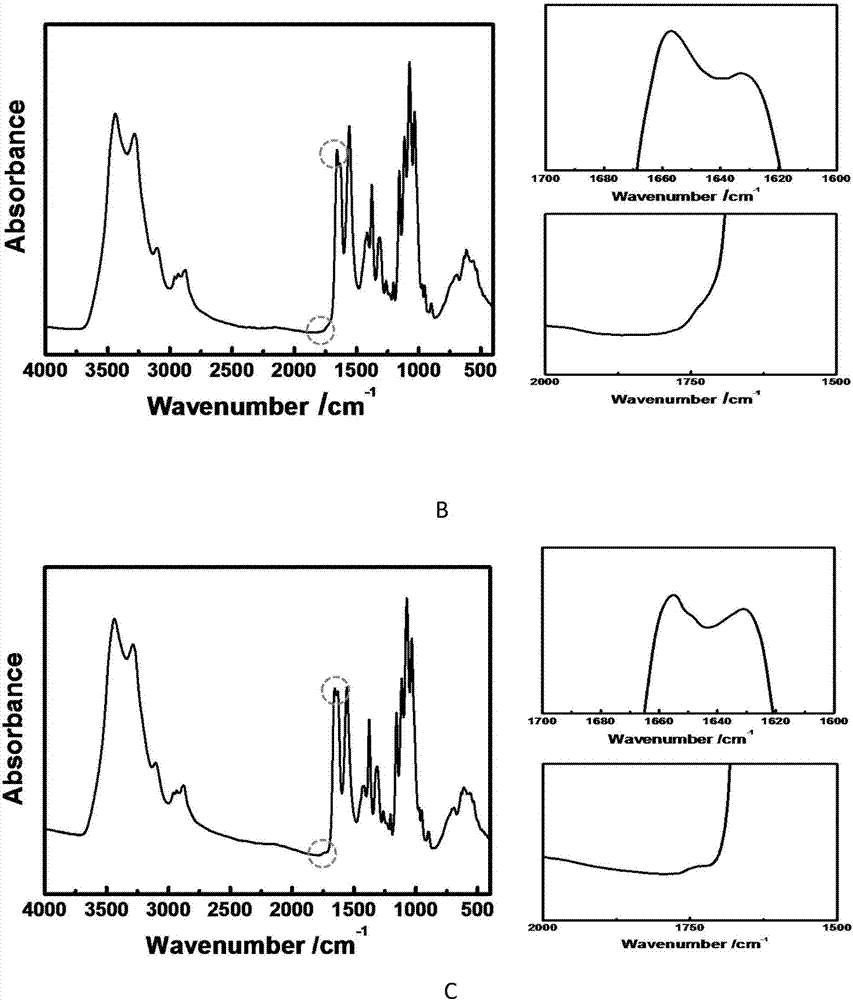

[0041] 1 gram of squid bone was added to 100 ml of 25wt% ammonium persulfate solution, stirred and heated at 60°C for 48 hours to obtain a chitin flocculent reactant, washed to neutrality, and prepared a 0.1wt% aqueous dispersion Using 4wt% sodium hydroxide to adjust the pH to 9,800 W and ultrasonic for 5 minutes to obtain a translucent aqueous dispersion of chitin nanofibers with carboxyl group-containing α and β crystal forms.

Embodiment 3

[0043] 2 grams of squid bone was added to 200 ml of 50wt% ammonium persulfate solution, stirred and heated at 70°C for 12 hours to obtain a chitin flocculent reactant, washed to neutrality, and prepared a 0.2wt% aqueous dispersion , Adjust the pH to 9 with sodium hydroxide with a concentration of 4 wt%, and ultrasound at 1000 W for 5 minutes to obtain a translucent aqueous dispersion of α-crystalline chitin nanofibers with carboxyl groups.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com