Electrolyte and preparation method therefor, and lithium-sulfur battery

An electrolyte and electrolyte technology, applied in non-aqueous electrolyte batteries, lithium batteries, secondary batteries, etc., can solve the problems of low coulombic efficiency of lithium-sulfur batteries, loss of positive active material, and rapid capacity decay, and achieve improved Coulombic efficiency and Capacity retention rate, effect of suppressing solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Preparation of electrolyte materials

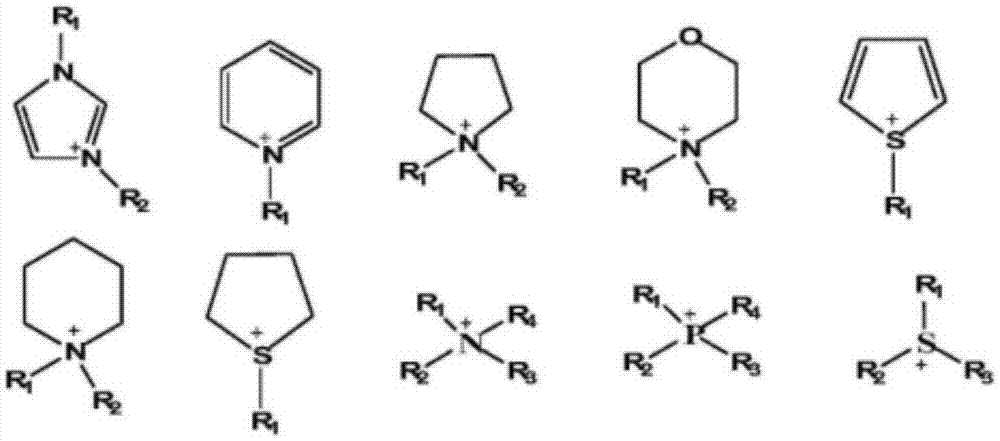

[0026] Lithium reference preparation of perfluoroalkylsulfonylimides. Preparation of ionic liquids containing ether functional groups.

[0027] 2. Preparation of electrolyte

[0028] In an argon atmosphere glove box (H2O<1ppm), dissolve 1M lithium trifluoromethanesulfonyl imide in N,N-diethyl-N,N-di(methoxyethyl)ammonium-tris In the fluoromethylsulfonylimide salt, fully stir evenly to obtain the lithium-sulfur battery electrolyte (free acid<5ppm, moisture<10ppm) of the present invention.

[0029] 3. Preparation of lithium-sulfur battery

[0030] Place the sulfur-based positive pole piece, the separator, and the lithium metal sheet in the battery case, add the electrolyte solution prepared in this example dropwise, and seal it to prepare a CR2025 button battery.

[0031] 4. Test method for flame retardant performance of electrolyte

[0032] Soak an equal weight of glass wool in the electrolyte solution for 10 minutes, then t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com