Feed fermentation agent and application in feed fermentation

A starter and feed raw material technology, applied in the field of microbial application and feed fermentation, can solve the problems of no fermentation, etc., achieve the effect of improving feed nutritional value and digestion and absorption rate, simple operation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A feed starter, characterized in that the feed starter is mixed in equal proportions from the fermentation liquid of Candida utilis and Lactobacillus plantarum; the preservation number of Candida utilis: CGMCC2.281; No.: CGMCC1.511, the concentration of Candida utilis reached 3.0×10 8 -5.0×10 8 CFU / mL, the concentration of Lactobacillus plantarum reaches 1.0×10 9 -5.0×10 9 CFU / mL; its preparation steps are as follows:

[0023] (1) Preparation of Candida utilis fermentation broth

[0024] The yeast strains preserved on the slant were inoculated on a fresh YPD medium plate and cultured at 25°C for 48h. Pick a ring from the plate, inoculate it in a 250mL Erlenmeyer flask containing 100mL seed medium, and culture it with shaking at 25°C and 150r / min shaker for 24h.

[0025] (2) Preparation of Lactobacillus plantarum fermentation broth

[0026] The puncture cultured lactic acid bacteria strains were inoculated on a fresh lactic acid bacteria medium plate and cultured a...

Embodiment 2

[0031] The application of feed starter in the fermentation of feed raw materials, the operation steps are as follows:

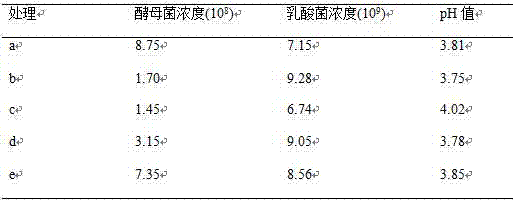

[0032] (1) Feed ingredients have the following combinations: a) Soybean meal, glucose 1.0%, K 2 HPO 4 0.2%, b) peanut meal, glucose 1.0%, K 2 HPO 4 0.2%, c) soybean meal 20%, bran 80%, glucose 1.0%, K 2 HPO 4 0.2%, d) soybean meal 20%, soybean skin 80%, glucose 1.0%, K 2 HPO 4 0.2%, e) full price feed, glucose 1.0%, K 2 HPO 4 0.2%.

[0033] (2) The material-to-water ratio of the above raw materials is 7:3, glucose and K 2 HPO 4 Add water to dissolve, and add feed starter to water according to 5% inoculum amount to obtain mixture A, add A to the fermentation raw material, and stir evenly to obtain mixture B.

[0034](3) Put B into a well-sealed plastic drum or plastic bag, and ferment at room temperature (20-30°C). The feed raw material emits an obvious sour aroma to complete the fermentation. Generally, it only takes 2 days. After fermentation, the...

Embodiment 3

[0039] Usage of Feed Raw Materials After Fermentation

[0040] Method: The experiment selected Penaeus vannamei with normal appearance and strong physique as the experimental shrimp, and each pond (20m 2 ) stocking 5000 Penaeus vannamei prawns, feeding 6% of the body weight every day, and feeding in four times, the control group was fed with conventional feed, and the treatment group was fed with 10% fermented feed added to the conventional feed. During the feeding period, the water temperature was (29±3)°C, and the water was continuously aerated. At the 6th week of the experiment, the intestinal tract was removed, the contents were removed, rinsed with deionized water, blotted dry with filter paper, weighed, crushed, added to 10 mL of sterile normal saline for homogenization, and the total number of bacteria and the number of Vibrio were measured after gradient dilution .

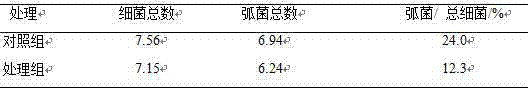

[0041] Results: It can be seen from Table 2 that the total number of bacteria and total number of Vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com