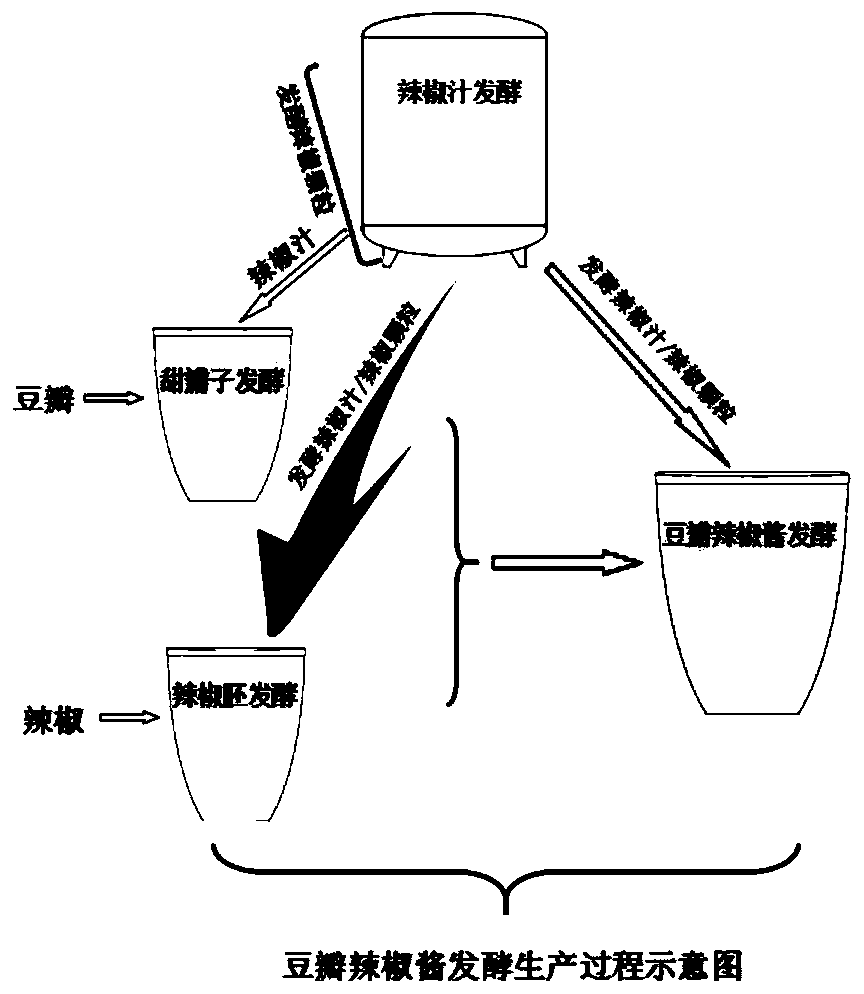

A kind of fermentation production method of watercress chili sauce

A kind of watercress chili sauce, technology of production method, applied in the direction of bacteria, bacteria, lactobacillus, etc. used in food preparation, can solve the problems of unstable quality of batch products, unsuitable control of fermentation process, low utilization rate of raw materials, etc., and achieve improvement The effects of product flavor, shortened fermentation cycle, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of lactic acid bacteria fermented chili juice and fermented chili particles.

[0033] (1) Preparation of lactic acid bacteria seed liquid:

[0034] Lactic acid bacteria were inoculated into MRS medium according to the inoculation amount of 1%-10%, and cultured at 25-37°C for 20-24 hours to form a seed culture solution. The seed culture solution is connected to the proliferation medium at a 1%-10% inoculum amount, and statically cultured at 30-40°C for 20-24 hours to form a lactic acid bacteria seed solution. Preferably, the lactic acid bacteria is Lactobacillus helveticus CGMCC No. 12062.

[0035] The MRS medium: glucose 2%, peptone 1%, beef extract 1%, yeast extract 0.5%, anhydrous sodium acetate 0.5%, Tween 80 0.1% (v / v), ammonium citrate 0.2%, Dipotassium hydrogen phosphate 0.2%, magnesium sulfate 0.058%, manganese sulfate 0.025%, the balance is water, and the pH is adjusted to 6.2-6.8.

[0036] The proliferation medium: glucose 2%, peptone 1%, beef extract 1%,...

Embodiment 2

[0042] Adding fermented chili juice during the preparation stage of Tianchuangzi to ferment to produce Douban chili sauce includes the following steps:

[0043] (1) Preparation of lactic acid bacteria seed solution: Leuconostoc mesenteroides are inoculated into MRS medium according to the inoculation amount of 1%-10%, and statically cultured at 30-37°C for 20-24 hours to form a seed culture solution. The seed culture solution is connected to the proliferation medium with an inoculum amount of 1%-10%, and statically cultured at 35-40°C for 20-24 hours to form a lactic acid bacteria seed solution.

[0044] (2) Preparation of fermented chili juice: After the chili is selected and washed, it is broken into 3cm-sized chili particles for later use. The fermenter is cleaned, after disinfection, the fermenter is rinsed with physiological saline and then discharged out of the fermentor. The processed pepper particles are added to salt water with a concentration of 15%-18%. The ratio of pepp...

Embodiment 3

[0052] Adding fermented chili juice at the stage of preparing chili embryos to ferment to produce bean curd chili sauce includes the following steps:

[0053] (1) Preparation of lactic acid bacteria seed liquid: Lactobacillus plantarum was inoculated into MRS medium according to the inoculation amount of 1%-10%, and cultured at 25-35°C for 20-24 hours to form a seed culture liquid. The seed culture solution is connected to the proliferation medium with an inoculum amount of 1%-10%, and statically cultured at 30-37°C for 20-24 hours to form a lactic acid bacteria seed solution.

[0054] (2) Preparation of fermented chili juice: After the chili is selected and washed, it is broken into 1cm-sized chili particles for use. Clean the fermentation tank, after disinfection, rinse the fermentation tank with physiological saline and discharge the fermentation tank. Add the processed pepper particles to salt water with a concentration of 15%-20%. The ratio of pepper to salt water is 1: 2-1:4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com