A preparation method and application of bone marrow protein and polypeptide

A protein and bone marrow technology, applied in the field of bone marrow protein and polypeptide preparation, can solve problems such as waste, environmental pollution, and non-utilization of livestock and poultry bones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

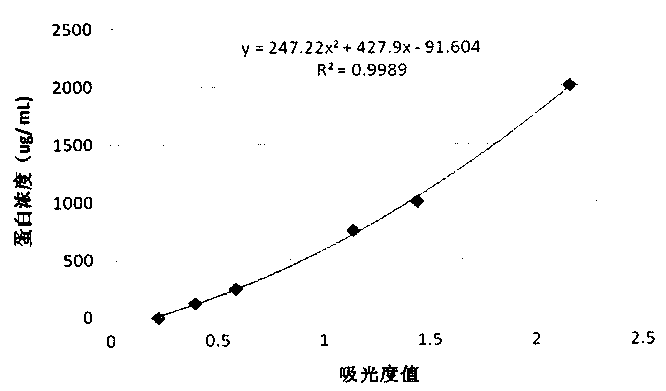

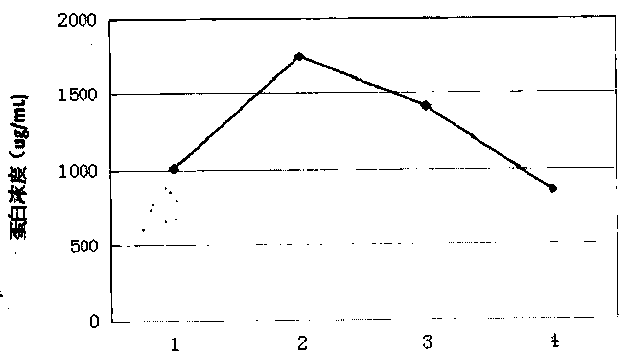

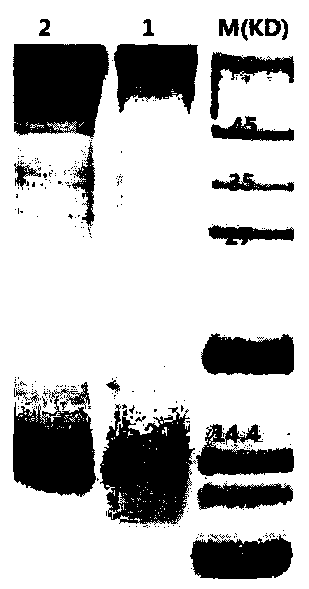

Image

Examples

Embodiment 1

[0034] a. Take 100g of fresh bone marrow, wash 3 times, remove broken bones and blood stains, pre-cool, chop into small pieces, add liquid nitrogen to crush at a weight ratio of 1:5, and crush 3-4 times repeatedly to obtain crushed bone marrow powder , Keep in low temperature refrigerator for later use;

[0035] b. Add distilled water with a weight ratio of 1:10 to the bone marrow sample that has been pulverized in step a, and set it on a magnetic stirrer for 2 hours at a temperature of 30°C. Extract twice at a time, filter under reduced pressure, combine the extracts, and separate impurities And get the extract for use;

[0036] c. Put the extract obtained in step b at 4°C overnight to separate the oil and water layers, take out the upper oil layer, place the lower extract layer in a separatory funnel, add petroleum ether according to the volume ratio of material to liquid of 1:5, and shake it constantly Carry out degreasing, stand for 3 hours until no oily matter is seen in the ...

Embodiment 2

[0041] a. Take 100g of fresh bone marrow and wash it 3 times to remove the broken bones and blood stains, cut into small pieces, add liquid nitrogen in a weight ratio of 1:5, and pulverize repeatedly 3-4 times to obtain bone marrow powder, low temperature Keep in the refrigerator for later use;

[0042] b. Add distilled water with a weight ratio of 1:10 to the bone marrow crushed powder in step a, and place it on a magnetic stirrer for 4 hours, at a temperature of 40°C, extract 3 times each time, filter under reduced pressure, combine the extracts, and separate impurities. Obtain the extract for use;

[0043] c. Put the extract obtained in step b at 4°C overnight to separate the oil and water layers, take out the upper oil layer, place the lower extract layer in a separatory funnel, add n-hexane according to the volume ratio of the material to liquid at 1:5, keep shaking Carry out degreasing, stand still for 5 hours until no oil-free matter is seen in the upper layer, and obtain a...

Embodiment 3

[0048] a. Take 100g of fresh bone marrow and wash it 3 times to remove the broken bones and blood stains, cut into small pieces, add liquid nitrogen at a weight ratio of 1:5, and smash it repeatedly for 3 times to obtain bone marrow powder, and store in a low-temperature refrigerator spare;

[0049] b. Add distilled water with a weight ratio of 1:10 to step a bone marrow crushed powder, set it on a magnetic stirrer for 4 hours, at a temperature of 35°C, extract twice each time, filter under reduced pressure, combine the extracts, and separate impurities. Obtain the extract for use;

[0050] c. Put the extract obtained in step b at 4°C overnight to separate the oil and water layers, take out the upper oil layer, place the lower extract layer in a separatory funnel, add n-hexane according to the volume ratio of the material to liquid at 1:5, keep shaking Carry out degreasing, stand for 4h until no oily matter is seen in the upper layer, and obtain a defatted crude extract;

[0051] d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com