Holographic polymer dispersed liquid crystal grating and preparation method thereof

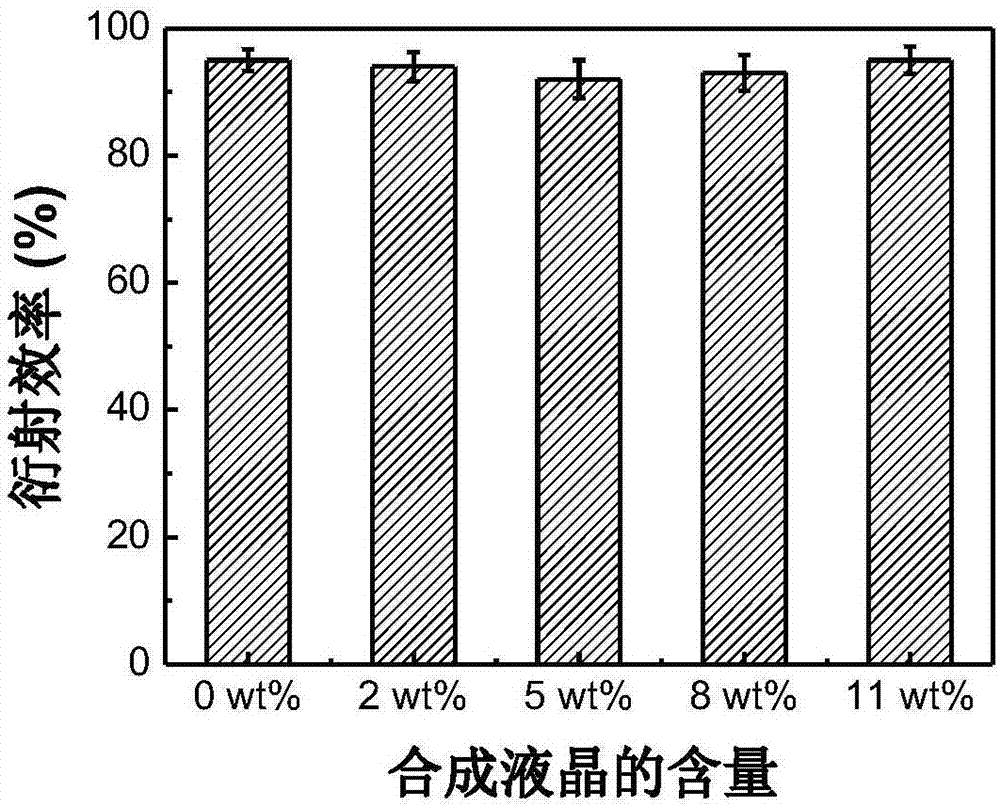

A technology for dispersing liquid crystals and polymers, applied in the direction of diffraction gratings, optics, optical elements, etc., can solve problems such as increasing the viscosity of the system, light scattering or light absorption, and affecting the comprehensive optical properties of holographic polymer dispersed liquid crystal gratings, etc., to improve diffraction Effect of Efficiency and Driving Voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The corresponding preparation method can be adopted in the following way: synthesizing biphenylcyanide liquid crystal compounds with different alkyl chain lengths, compounding them with common commercial liquid crystals, compounding them with monomers, and further performing grating recording, so as to obtain simultaneously Holographic polymer dispersed liquid crystal composite gratings with high diffraction efficiency and low driving voltage. The specific steps can be as follows:

[0051] 1. Synthesis of liquid crystal nOCB;

[0052] (1) The ketone solution of 4-hydroxyl-4'-biphenylnitrile and NaOH is added in the round bottom flask, constant temperature;

[0053] (2) in the mixed solution that step (1) makes dropwise add Br(C n h 2n+1 ) of the ketone solution, backflow;

[0054] (3) Cool to room temperature, filter, wash the filtrate several times with NaOH aqueous solution, extract, and recrystallize from ethanol to obtain nOCB as a white solid product.

[0055]...

Embodiment 1

[0078] This embodiment includes the following steps:

[0079] 1. Synthetic liquid crystal 7OCB;

[0080] (1) The butanone solution of 4-hydroxyl-4'-biphenylnitrile and NaOH is added in the round bottom flask, and kept at a constant temperature of 30 minutes at 30°C; constant temperature treatment can make 4-hydroxyl-4'-biphenylnitrile and Sodium hydroxide reacts to generate sodium salt, and the constant temperature and time are all conducive to improving the reaction rate and yield.

[0081] (2) Add BrC dropwise to the mixed solution prepared in step (1) 7 h 15 Butanone solution (0.8mol / L), was refluxed at 80°C for 17 hours;

[0082] (3) Cool to room temperature, filter, and wash the filtrate several times with 0.2 mol / L NaOH aqueous solution, extract with toluene, and recrystallize with ethanol to obtain the white solid product 7OCB.

[0083] 2. Compounding of synthetic liquid crystals and commercial liquid crystals;

[0084] Add the synthesized liquid crystal 7OCB and t...

Embodiment 2

[0092] 1. Synthetic liquid crystal 9OCB;

[0093] (1) Add the 2-pentanone solution of 4-hydroxy-4'-biphenylnitrile and NaOH into the round bottom flask, and keep the temperature at 30° C. for 40 minutes;

[0094] (2) Add BrC dropwise to the mixed solution prepared in step (1) 9 h 19 2-pentanone solution (0.5mol / L), refluxed at 90°C for 18 hours;

[0095] (3) Cool to room temperature, filter, and wash the filtrate several times with 0.5 mol / L NaOH aqueous solution, extract with chloroform, and recrystallize with ethanol to obtain the white solid product 9OCB.

[0096] 2. Compounding of synthetic liquid crystals and commercial liquid crystals;

[0097] Add the synthesized liquid crystal 9OCB and the commercialized liquid crystal ZLI-4792 in a certain mass ratio into a 5 ml brown sample bottle, and ultrasonicate at 30° C. for 20 minutes to obtain a homogeneous mixture. The mass ratio of the synthesized liquid crystal to the commercial liquid crystal is 17 / 33.

[0098] 3. Pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com