Aluminiferous SiO2 loaded high-dispersion Pt catalyst, and preparation method and application thereof

A highly dispersed and catalytic technology, applied in the field of air pollution control, can solve the problems of catalytic combustion waste, high load capacity, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

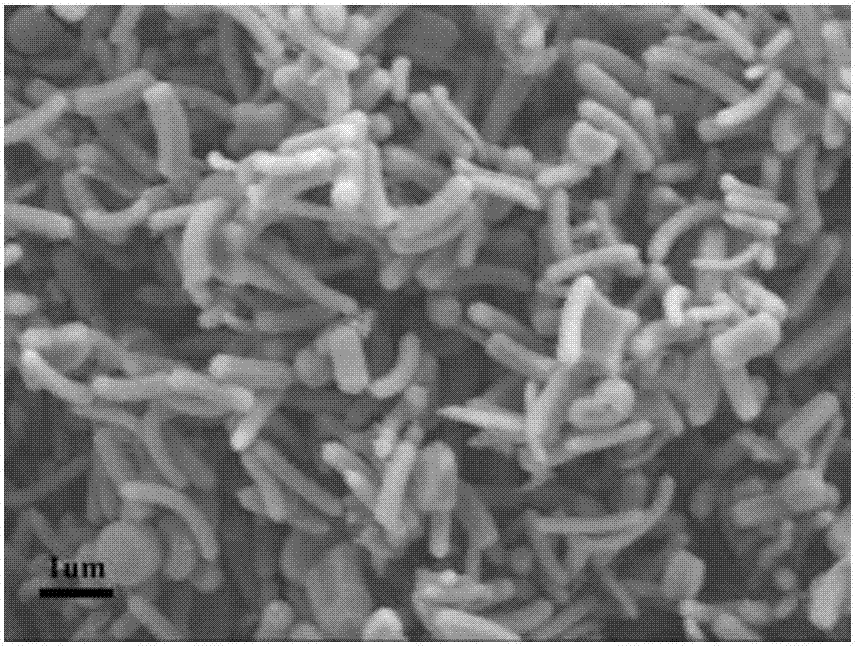

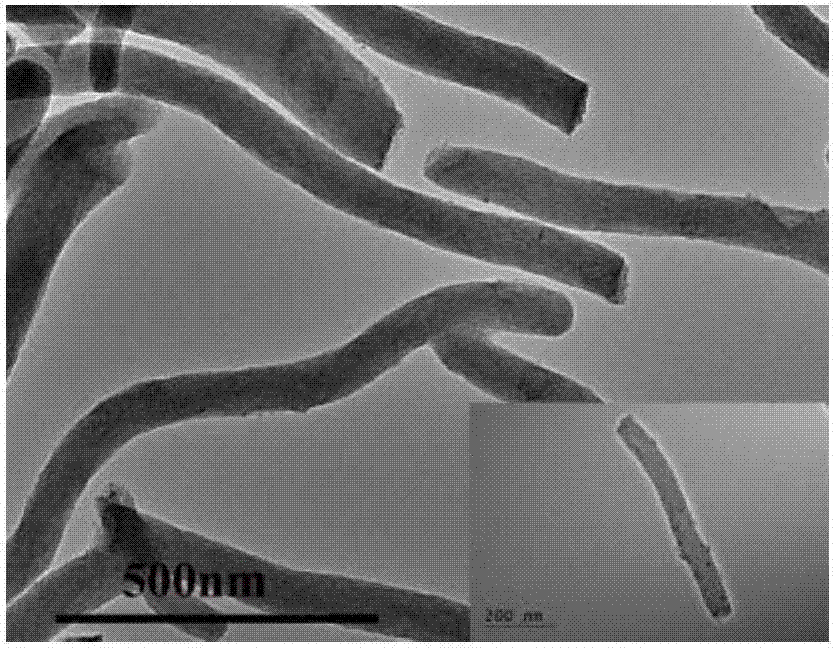

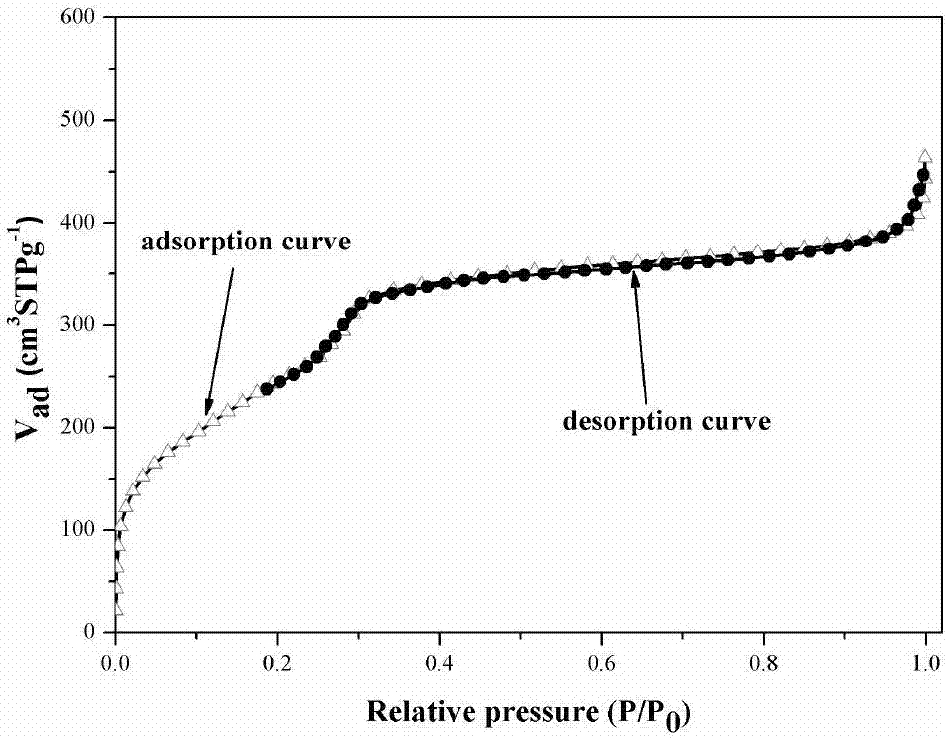

[0043] 1) Preparation of rod-shaped silica with high specific surface area by double surfactant method and hydrothermal synthesis method:

[0044] Put 1g of cetyltrimethylammonium bromide (CTAB) and 100mL of ammonia water (concentration: 25%) in a 500mL round-bottomed flask, stir and mix evenly at room temperature, and add 0.06g of Polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123), at a stirring rate of 300 rpm, the temperature was raised to 40 degrees Celsius. When the reaction solution became clear, 2 mL of tetraethyl orthosilicate (TEOS) was added quickly, and stirring was continued at 40° C. for 3 h.

[0045] The obtained microemulsion was placed in a 250 mL polytetrafluoroethylene-lined stainless steel autoclave for hydrothermal crystallization at 100 °C for 24 h. After cooling down to room temperature, the mixture was filtered, washed with absolute ethanol and deionized water, dried at room temperature for 48 hours, and calcined in a mu...

Embodiment 2

[0055] The difference from Example 1 is that in step 4), 3mL of the PVP-Pt-containing ethanol solution obtained in step 3) is taken, and the final preparation is Pt / K-(Al)SiO with a loading capacity of 0.3wt%. 2 catalyst.

Embodiment 3

[0057] The difference from Example 1 is that in step 4), 1mL of the ethanol solution containing PVP-Pt obtained in step 3) is taken, and the Pt / K-(Al)SiO with a loading capacity of 0.1wt% is finally prepared. 2 catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com