A kind of modified molybdenum disulfide for heavy metal ion adsorption and preparation method thereof

A heavy metal ion, molybdenum disulfide technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of long preparation cycle, complex preparation process, poor environmental protection, etc. The preparation method is simple and the effect of delamination is favorable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

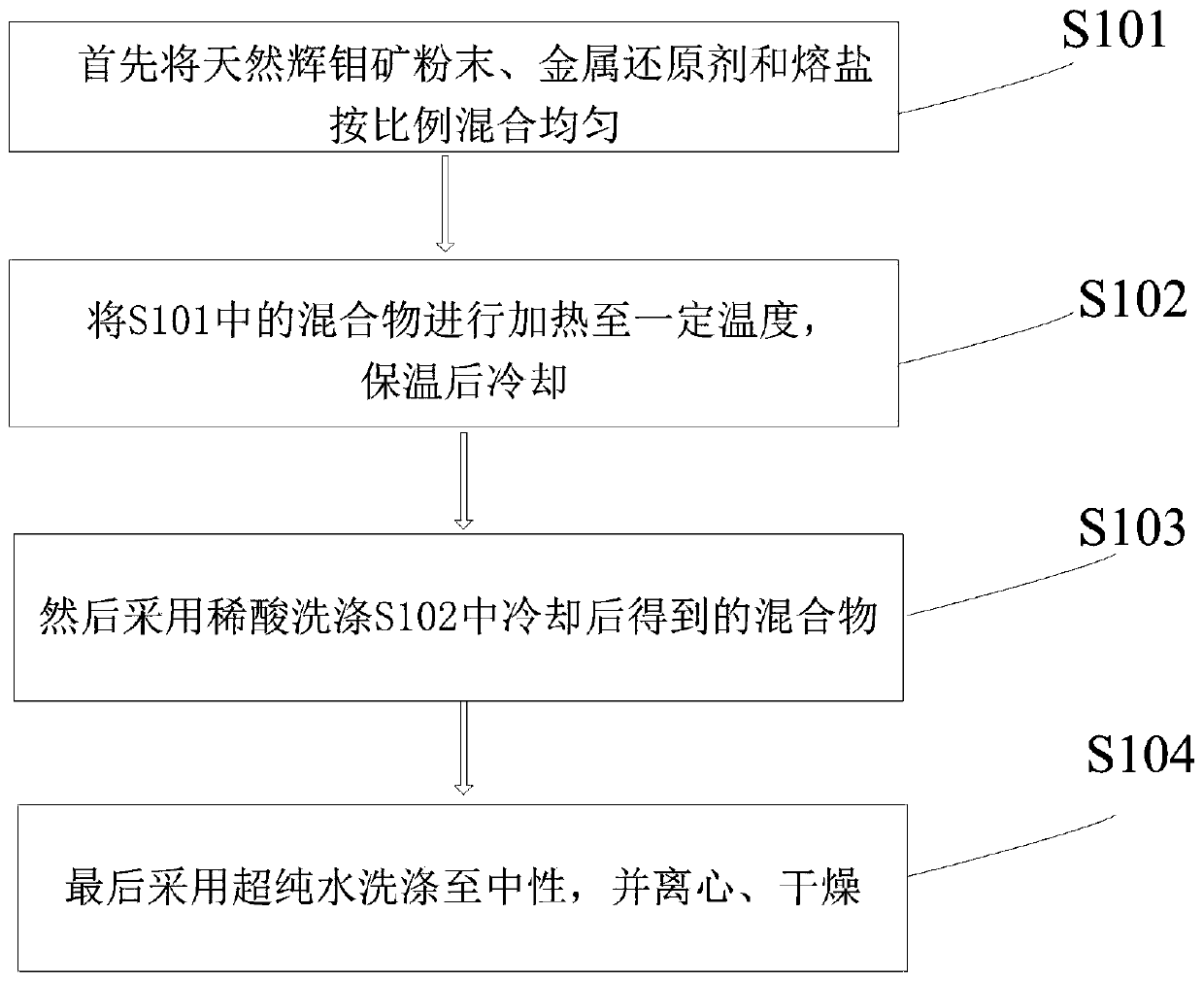

[0026] A modified molybdenum disulfide for heavy metal ion adsorption and a preparation method thereof specifically comprises the following steps:

[0027] S101: first mix the natural molybdenite powder, metal reducing agent and molten salt in proportion;

[0028] S102: heating the mixture in S101 to a certain temperature, cooling after keeping warm;

[0029] S103: washing the mixture obtained after cooling in S102 with dilute acid;

[0030] S104: Finally, wash with ultrapure water until neutral, centrifuge, and dry.

[0031] Preferably, in S101, the molar ratio of the natural molybdenite powder, metal reducing agent and molten salt is 1:(0.1-2):(3-15).

[0032] Preferably, in S101, the MoS in the natural molybdenite 2 The content is greater than 90wt%; the metal reducing agent is selected from metal sodium, metal potassium, metal calcium, metal magnesium, metal aluminum, metal iron, metal zinc and one or more of the above metals; the molten salt is selected from One or mo...

Embodiment 1

[0040] A modified molybdenum disulfide for heavy metal ion adsorption and a preparation method thereof, comprising the following steps:

[0041] 1) Get 1g of natural molybdenite powder, 0.1g metal magnesium and 3g sodium chloride and mix evenly, place in a small ceramic boat, then place the small ceramic boat filled with the above mixture in a tube furnace, Heating to 650°C in an argon atmosphere, holding the temperature for 4 hours, and cooling naturally;

[0042] 2) The mixture obtained above was washed with 7% dilute hydrochloric acid for 3 hours, then washed with ultrapure water until neutral, centrifuged and dried to obtain the modified molybdenum disulfide.

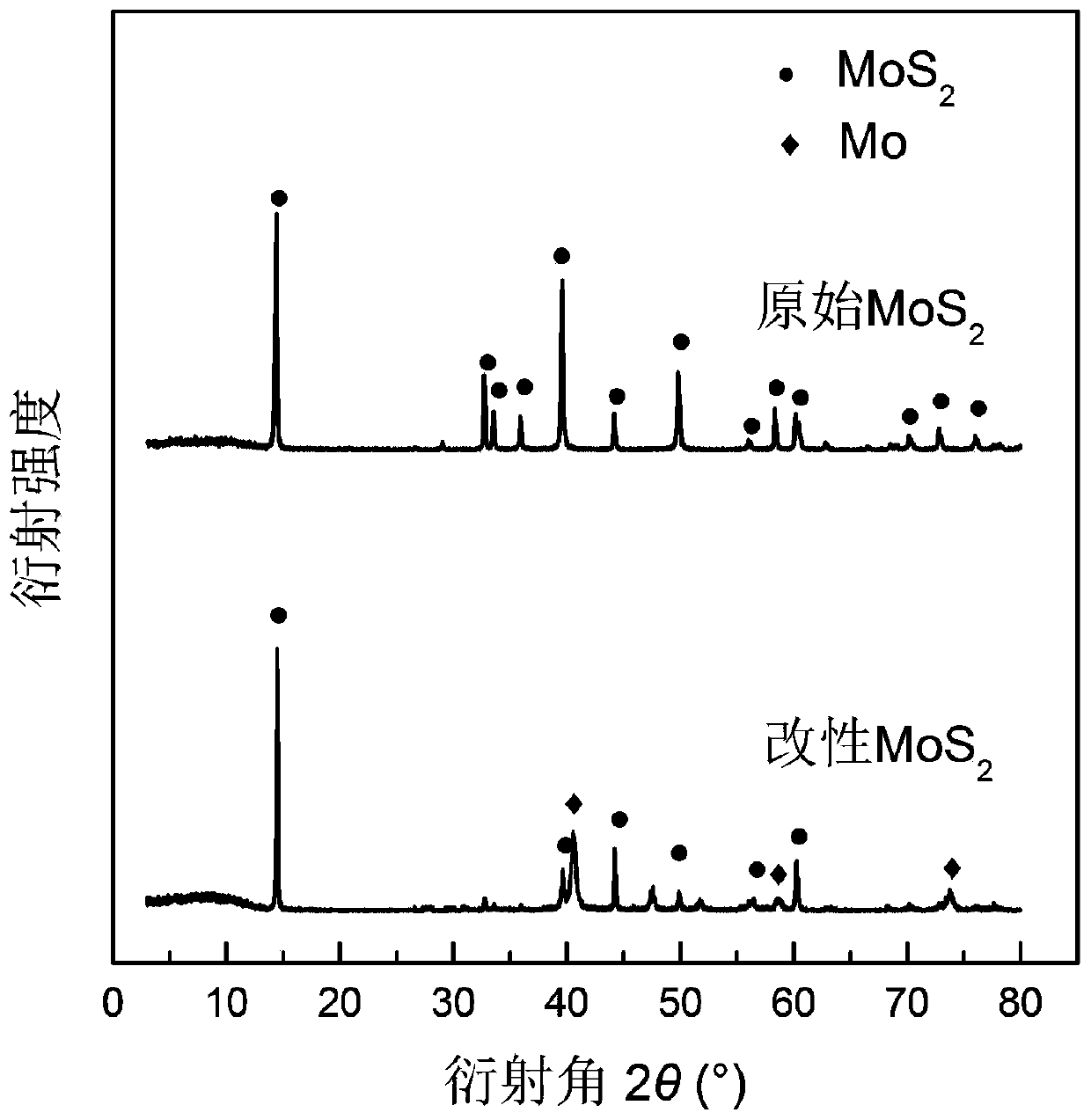

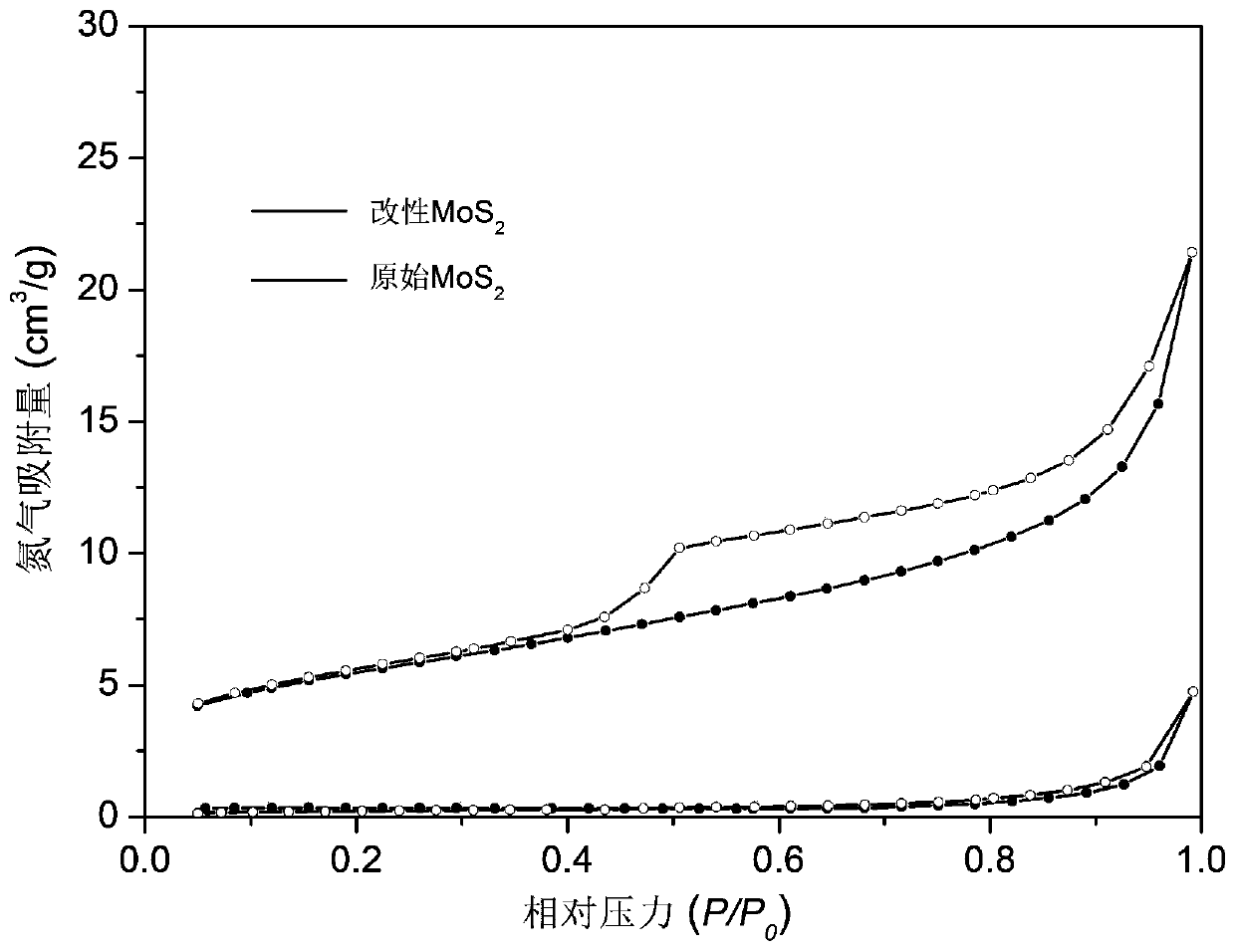

[0043] X-ray diffraction spectrum (XRD) ( figure 2 ) shows that the original molybdenum disulfide shows clearly visible elemental MoS2 characteristic diffraction peaks, no other miscellaneous peaks appear, indicating that the precursor used is relatively pure; after modification by the method of the present invent...

Embodiment 2

[0048] A modified molybdenum disulfide for heavy metal ion adsorption and a preparation method thereof, comprising the following steps:

[0049] 1) Take 2g of natural molybdenite powder, 0.5g of metal Al and 7g of sodium chloride and mix them evenly, place them in a corundum crucible, then place the corundum crucible containing the above mixture in a tube furnace, in a helium atmosphere Heat to 700°C, keep warm for 5h, and cool naturally;

[0050] 2) The mixture obtained above was washed with 5% dilute hydrochloric acid for 5 hours, then washed with ultrapure water until neutral, centrifuged and dried to obtain the modified molybdenum disulfide.

[0051] The obtained modified molybdenum disulfide has similar characteristics to those in Example 1, and has better adsorption effect on heavy metal ions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com