Method for solving secondary pollution of cyclohexanone saponification waste alkali liquor

A secondary pollution, cyclohexanone technology, applied in chemical instruments and methods, preparation of organic compounds, inorganic chemistry and other directions, can solve secondary pollution, equipment corrosion and other problems, achieve good economic benefits, solve equipment corrosion, process cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

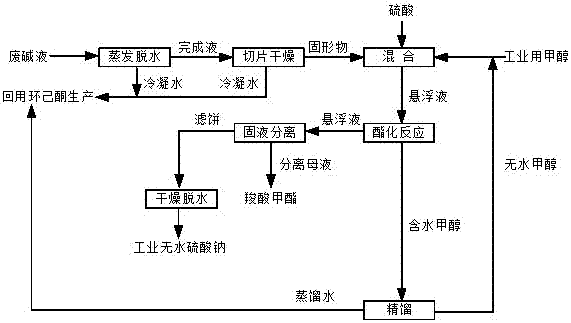

Image

Examples

Embodiment 1

[0026] (1), take 1000 grams of waste lye with a solid content of 35%wt, enter the rotary evaporator, and when the solid content of the waste lye is 80%wt, stop evaporation to obtain 440 grams of evaporated liquid and 560 grams of condensed water grams; after testing, the condensed water meets the water standard for cyclohexanone production. The obtained 440 grams of evaporated liquid is put into a desiccator with condensation receiver, and after drying, 360 grams of solids and 80 grams of condensed water are obtained, which can be reused in the production of cyclohexanone after testing.

[0027] (2) Put 360 grams of solid matter into a three-necked flask with stirring and condensing reflux, add 90 grams of industrial methanol, stir and mix, then slowly add 140 grams of sulfuric acid (100% by mass fraction), and the flask appears When the suspension is uniform, keep the temperature of the material at 110°C for reflux reaction. After two hours, the acid value of the reaction mat...

Embodiment 2

[0029] (1), get 1,000 kilograms of waste lye with a solid content of 35%wt, pump it into a single-effect evaporator with a condensing device, evaporate condensed water into the collection tank, and when the solid content of the waste lye reaches 70%wt, Stop the evaporation to obtain 500 kg of evaporated liquid and 500 kg of condensed water; after testing, the condensed water can be reused for the production of cyclohexanone.

[0030] The obtained 500 kg of evaporated liquid is entered into a drum chip dryer with a condensing device for drying to obtain 350 kg of waste lye flake solids and 150 kg of condensed water. The dried condensed water meets the water standard for cyclohexanone production.

[0031] (2) Put 350 kg of solid matter into a reaction kettle with a stirring and condensing reflux device, add 14 kg of industrial methanol, stir and mix, then slowly add 170 kg of sulfuric acid (100% by mass fraction), the contents of the kettle When it is a uniform suspension, keep ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com