Application of apatite substance in catalytic hydrogenation and tetrahydrofurfuryl alcohol preparation method

A technology for catalytic hydrogenation and tetrahydrofurfuryl alcohol, applied in chemical instruments and methods, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of poor selectivity of tetrahydrofurfuryl alcohol, harsh catalytic reaction conditions of catalysts, etc., and achieve mild reaction conditions , high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] 1. The supported Pd catalyst used in the following examples is prepared according to the following method:

[0055] Using 0.456mg Pd(OAC) per ml 2 100mL of acetone solution, impregnated with 1.00g of apatite carrier HAP (Ca 5 (PO 4 ) 3 (OH)), stirred for 24 h until adsorption equilibrium was reached, filtered and washed with acetone, dried at 40°C for 10 h, and then washed with H at 280°C 2 Reduction 3 hours, obtain the loaded Pd catalyst that the mass fraction of loaded palladium is 1%, chemical formula is Pd / Ca 5 (PO 4 ) 3 (OH), abbreviated as Pd-HAP.

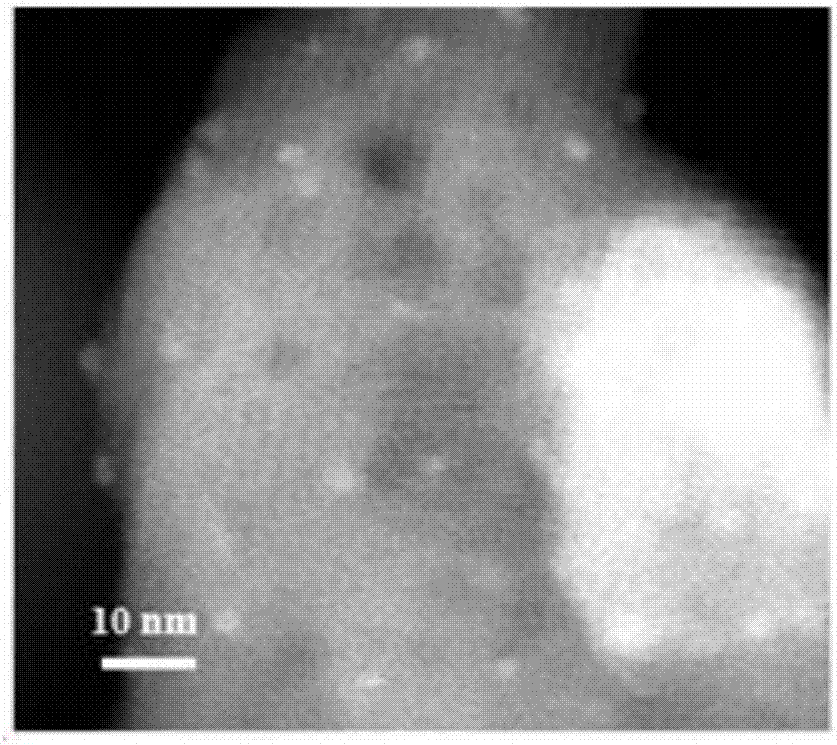

[0056] Electron microscopy analysis, X-ray diffraction analysis and thermogravimetric analysis were carried out on the carrier and the loaded product, the results can be found in Figure 1-5 . figure 1 It is the SEM photo of HAP in embodiment 1, figure 2 It is the SEM photo of Pd-HAP in embodiment 1, image 3 It is the AADF-STEM photo of Pd-HAP in embodiment 1, Figure 4 Be the XRD pattern of HAP and Pd-HAP...

Embodiment 2~6

[0064] 1. Load Pd to Mg separately 2 Ca 3 (PO 4 ) 3 (OH), Ce 5 (VO 4 ) 6 (OH) 2 , Ca 5 (PO 4 ) 3 (HCO 3 ), Ca 5 (PO 4 ) 3 F. Na 10 (PO 4 ) 3 On (OH) carrier, the supported Pd catalyst of different carrier is obtained, and preparation method is the same as embodiment 1.

[0065] 2. Using these catalysts respectively at 40° C., 1 MPa hydrogen gas, in isopropanol solvent, react for 3 h, and prepare tetrahydrofurfuryl alcohol by catalytic furfural hydrogenation one-pot method, and the reaction conditions are the same as in Example 1.

[0066] According to the gas chromatographic analysis method in Example 1, the catalytic furfural hydrogenation reaction solution was analyzed, and the results are shown in Table 1 for the results of experiment numbers 2-6.

Embodiment 7~12

[0072] The material (preparation method is similar to Example 1) loaded on the apatite carrier HAP with the metal Pd of different loads (0.5%, 1%, 2%, 3%, 4%, 5%) respectively, as a load Type metal catalyst, at 60 ℃, 2MPa hydrogen, in ethanol solvent, react for 4h, catalyze furfural hydrogenation one-pot method to prepare tetrahydrofurfuryl alcohol. Specifically include:

[0073] Add 100mg of furfural and 30mg of metal catalysts loaded on apatite carrier in a 50mL reactor, add 10mL of ethanol, set the hydrogen pressure to 2MPa, heat to 60°C, and react under stirring conditions. After 4 hours, cool, deflate, and filter to separate the catalyst from the reaction solution. After the reaction solution is diluted with isopropanol, it is analyzed by gas chromatography. The gas chromatographic conditions are the same as in Example 1, and the gas chromatographic analysis results of the three repeated experiments are shown in Table 1 for the results of experiment numbers 13-18.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com