Preparation method of ternary zinc oxide and zinc telluride tellurium nano composition

A zinc oxide and tellurium nanotechnology, applied in the direction of zinc oxide/zinc hydroxide, selenium/tellurium compound, metal selenide/telluride, etc., can solve the high requirements and danger of binary zinc oxide zinc telluride compound experiment The problems of high coefficient and cost, low operability, etc., to achieve the effect of controllable product morphology, low cost and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

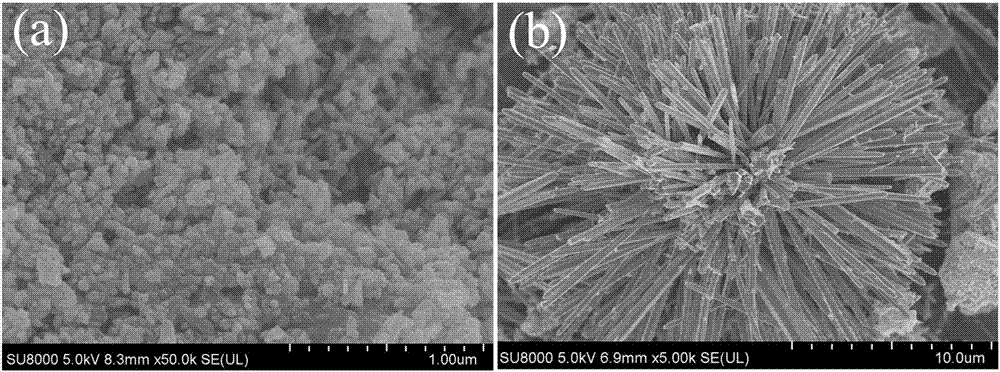

[0022] Firstly, ZnO rice particles were prepared and synthesized using a solid-phase method. Pour zinc nitrate and sodium hydroxide with a molar ratio of 2:1 into the mortar and grind for half an hour. Wash and dry, collect samples. In the lining of the autoclave, weigh 2mmol of zinc oxide, 1mmol of sodium selenite and 0.02mmol of polyvinylpyrrolidone powder and add hydrazine hydrate, diethyltetrahexylamine, and deionized water in sequence. In the mixed solution (the mixing ratio is 10:2:10), stir evenly, place in a constant temperature drying oven at 200°C for 24 hours, and cool naturally to room temperature. The samples were washed several times, dried in a vacuum oven at a constant temperature of 60 °C for 6 h, and then annealed in a tube furnace at 400 °C for 2 hours to obtain zinc oxide telluride zinc telluride composites.

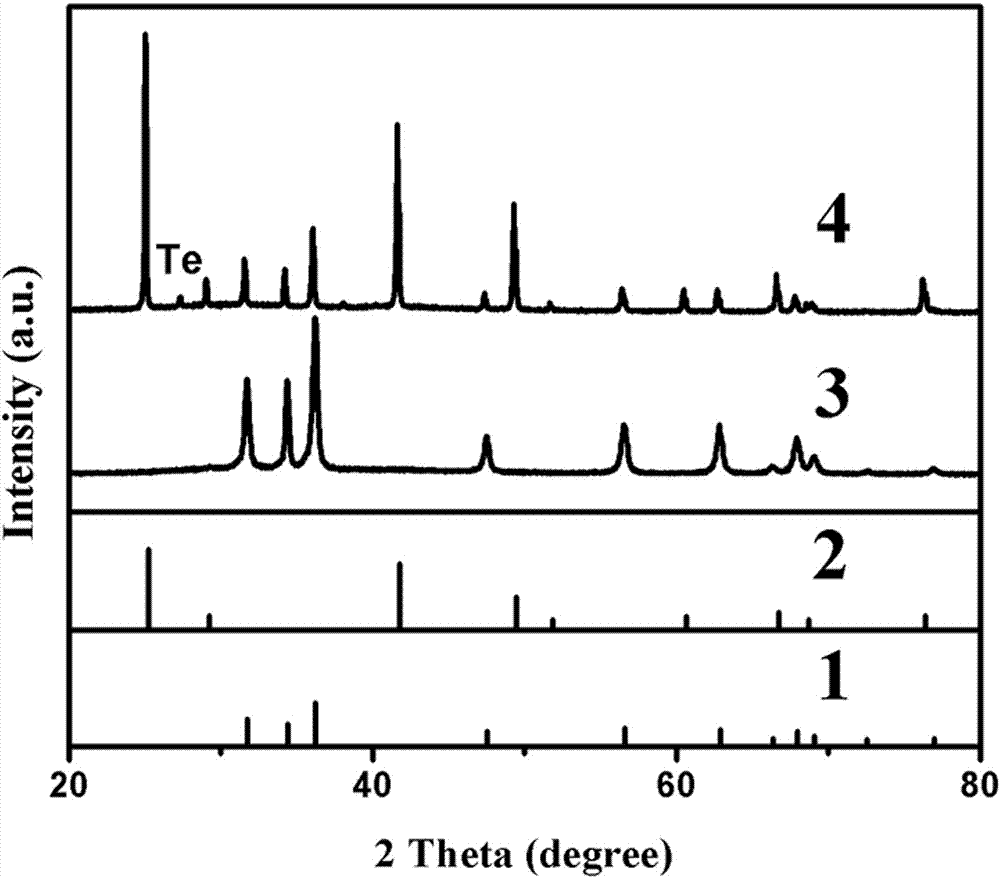

[0023] Such as figure 1 Shown are the XRD patterns of zinc oxide nanoparticles and zinc oxide zinc telluride nanocomposites. The XRD diffraction ...

Embodiment 2

[0026] In the lining of the autoclave, weigh 2mmol of zinc oxide, 1mmol of sodium selenite and 0.02mmol of polyvinylpyrrolidone powder and add hydrazine hydrate, diethyltetrahexylamine, and deionized water in sequence. In the mixed solution (the mixing ratio is 10:1.5:10), stir evenly, place in a constant temperature drying oven at 200°C for 24 hours, and cool naturally to room temperature. The samples were washed several times, dried in a vacuum oven at a constant temperature of 60 °C for 6 h, and then annealed in a tube furnace at 400 °C for 2 hours to obtain zinc oxide telluride zinc telluride composites.

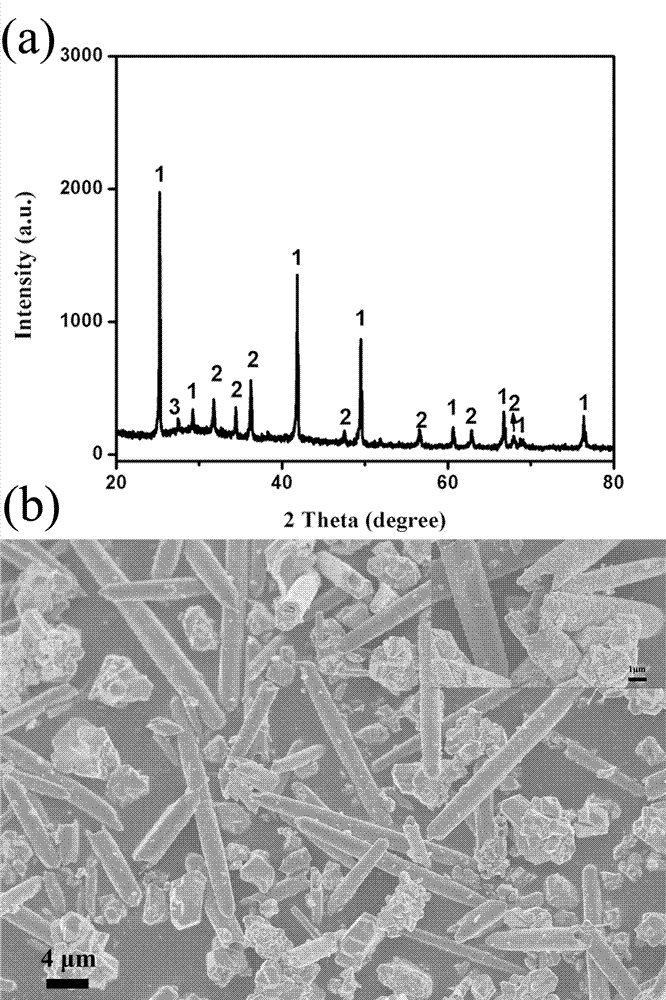

[0027] Such as image 3 Shown are the XRD and SEM images of the obtained product. The XRD diffraction peaks of the sample are mixed peaks of the three substances, and 1, 2, and 3 correspond to zinc oxide PDF36-1451, zinc telluride PDF15-0746 and tellurium PDF36-1452 cards respectively. . From the SEM image, it can be clearly seen that the sample is a hollow nanotube, t...

Embodiment 3

[0029] In the lining of the autoclave, weigh 2mmol of zinc oxide, 1mmol of sodium selenite and 0.02mmol of polyvinylpyrrolidone powder and add hydrazine hydrate, diethyltetrahexylamine, and deionized water in sequence. In the mixed solution (the mixing ratio is 10:4:10), stir evenly, place in a constant temperature drying oven at 200°C for 24 hours, and cool naturally to room temperature. The samples were washed several times, dried in a vacuum oven at a constant temperature of 60 °C for 6 h, and then annealed in a tube furnace at 400 °C for 2 hours to obtain zinc oxide telluride zinc telluride composites.

[0030] Such as Figure 4 Shown are the XRD and SEM images of the obtained product. The XRD diffraction peaks of the sample are mixed peaks of the three substances, 1, 2, and 3 respectively correspond to zinc oxide PDF36-1451, zinc telluride PDF15-0746 and tellurium PDF36-1452 cards . From the SEM image, it can be clearly seen that the sample is composed of a large number...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com