Deoxidizing reaction device for oxygen-containing coalbed methane

A technology of reaction device and deoxygenation reactor, which is applied in the direction of gas fuel, petroleum industry, chemical instruments and methods, etc., can solve the problems of poor catalytic reaction effect, short service life of catalyst, difficult plugging of tubes, etc., and achieve low CO generation The effect of carbon deposition amount, long catalyst life and high O2 removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

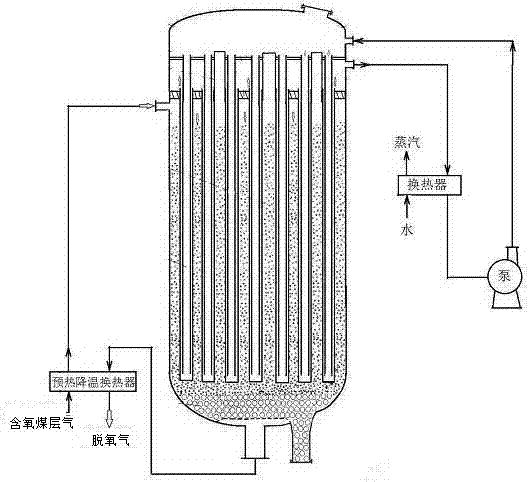

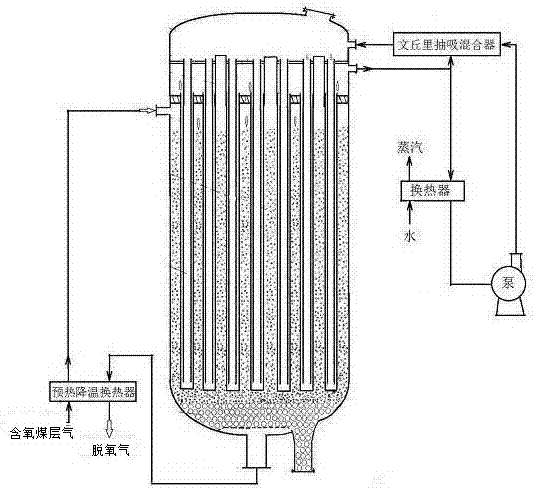

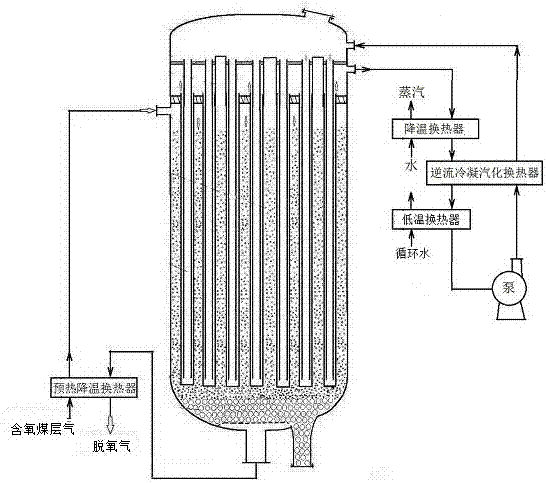

[0033] Example 1 is attached figure 2 A set of oxygen-containing coalbed methane deoxidation reaction test device shown mainly includes a catalytic reactor body and a heat transfer temperature control system;

[0034] The main body of the catalytic reactor is attached Image 6 As shown, it includes a shell 1, a catalyst reaction bed 2 with an axial structure, an inlet and outlet 15, a catalyst filling pipe 3, and a catalyst discharge port 14. The lower part of the catalyst bed is supported by ceramic balls 11, and the reaction material in the catalyst bed The flow direction is up and down; the top is provided with a heat transfer medium distribution chamber 4 and a return chamber 21, and the low-temperature heat transfer medium before absorbing heat enters the heat transfer medium distribution chamber 4 through the heat transfer medium inlet, and distributes the heat transfer medium that flows downward into the casing 10. Inner pipe 5, under the distribution chamber is heat ...

Embodiment 2

[0054] After the above test is completed, remove the Venturi suction mixer and high-pressure centrifugal fan in the heat transfer medium circulation pipeline, install a molten salt circulation pump, and replace it with an attached figure 1 The process is to use 53% potassium nitrate, 40% sodium nitrite, and 7% sodium nitrate ternary eutectic mixed molten salt as the heat transfer medium, circulate through the molten salt pump, and circulate the molten salt through the by-product steam of the heat exchanger. The heat in the coal bed gas was taken away and the temperature was lowered by about 30°C. Operation tests of various process conditions were carried out. Each process condition was operated for 48 hours. The temperature, pressure, flow conditions and main composition of coalbed methane before and after deoxidation are shown in Table 6 below. -8 listed. During the test, the molten salt pressure in the reflux chamber is controlled at about 5kPa by controlling the molten salt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com