Lithium ion battery layered positive electrode material doped with metal ions, and preparation method thereof

A lithium-ion battery and metal ion technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as voltage attenuation and poor rate performance of lithium-rich cathode materials, and achieve shortened synthesis cycle, optimized performance, and short synthesis cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

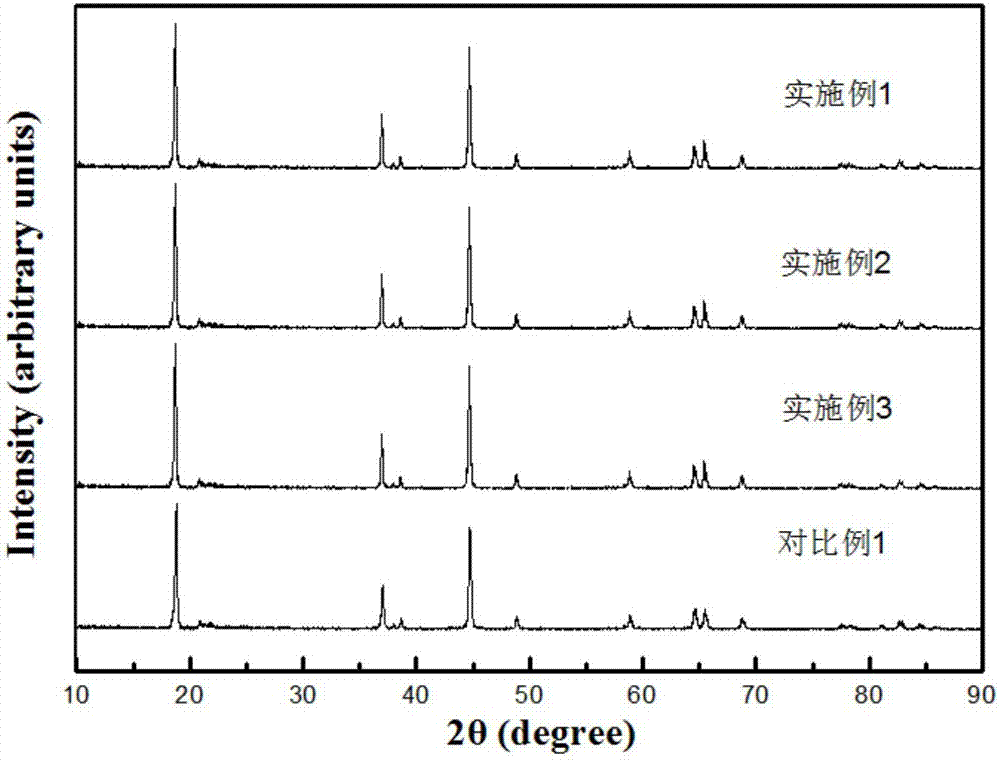

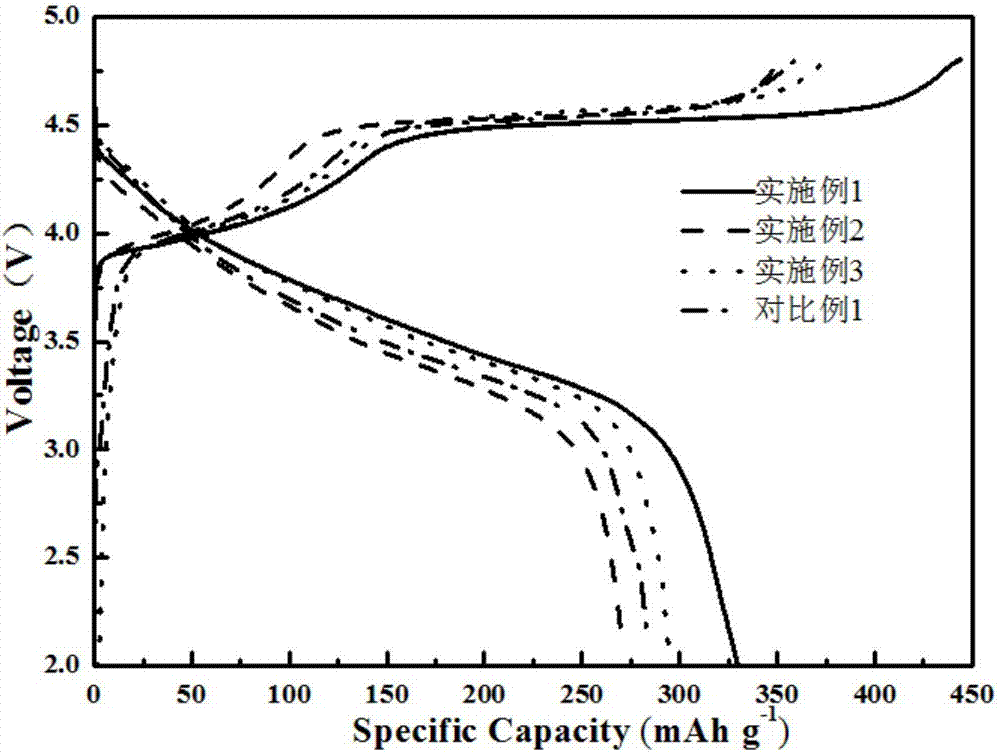

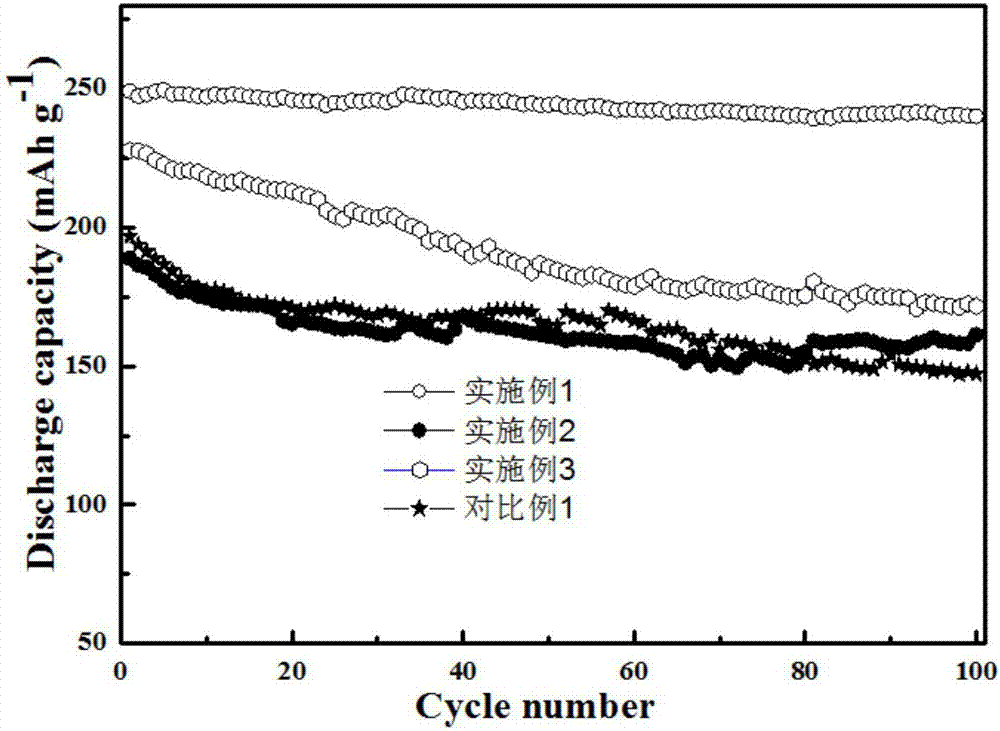

[0032] In this embodiment, Sb element is doped into Li 1.2 mn 0.54 co 0.13 Ni 0.13 o 2 Layered lithium-rich cathode materials. The specific implementation is as follows: Weigh 4.8691g of lithium acetate dihydrate, 1.2688g of nickel acetate tetrahydrate, 4.8765g of manganese acetate tetrahydrate, 1.2512g of cobalt acetate tetrahydrate, and 0.0924g of antimony acetate tetrahydrate, dissolve them in 40mL of ethanol, and stir until completely To dissolve, slowly pour 16.6298 g of oxalic acid into 40 mL of ethanol solution at room temperature of 25 ° C into the metal salt solution for co-precipitation, and continue stirring for 30 min. Transfer the above co-precipitation suspension to a reaction kettle, react with solvothermal reaction at 180°C for 24 hours, wash and filter the product with alcohol after natural cooling, dry the precipitate and place it in a muffle furnace, and pre-heat it at 450°C in an air atmosphere. Calcined for 5 hours, and then calcined at 900° C. for 12...

Embodiment 2

[0035] In this embodiment, Sb element is doped into Li 1.2 mn 0.54 co 0.13 Ni 0.13 o 2 Layered lithium-rich cathode materials. The specific implementation is: take by weighing 4.8691g of lithium acetate dihydrate, 1.2688g of nickel sulfate tetrahydrate, 4.7280g of manganese sulfate tetrahydrate, 1.6934g of cobalt sulfate tetrahydrate, and 0.2273g of antimony acetate tetrahydrate and dissolve them in 40mL of ethylene glycol, stirring until completely dissolved. At room temperature of 25°C, 40 mL of ethylene glycol solution dissolved with 15.3247 g of ammonium bicarbonate was slowly poured into the metal salt solution for co-precipitation, and the stirring was continued for 30 min. Transfer the above co-precipitation suspension to a reaction kettle, react with solvothermal reaction at 180°C for 24 hours, wash and filter the product with alcohol after natural cooling, dry the precipitate and place it in a muffle furnace, and pre-heat it at 450°C in an air atmosphere. Calcin...

Embodiment 3

[0037] In this embodiment, Sb element is doped into Li 1.2 mn 0.54 co 0.13 Ni 0.13 o 2 Layered lithium-rich cathode materials. The specific implementation is as follows: Weigh 4.8691g of lithium carbonate dihydrate, 1.2688g of nickel acetate tetrahydrate, 4.5795g of manganese acetate tetrahydrate, 1.2512g of cobalt acetate tetrahydrate, and 0.4622g of antimony acetate tetrahydrate are dissolved in 40mL of ethanol and stirred until completely To dissolve, slowly pour 40 mL of ethanol solution dissolved with 16.6298 g of oxalic acid into it for co-precipitation, and keep stirring for 30 min. Transfer the above co-precipitation suspension to a reaction kettle, and react with solvothermal reaction at 180°C for 24 hours. After natural cooling, the product is washed and filtered with alcohol, and the precipitate is dried and placed in a muffle furnace. Calcined for 5 hours, and then calcined at 880° C. for 12 hours, the obtained powder is the layered lithium-rich cathode materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com