Bio-organic fertilizer for preventing tomato autotoxicity and preparation and using methods thereof

A bio-organic fertilizer and tomato technology, which is applied in the preparation of organic fertilizers, the treatment of bio-organic parts, organic fertilizers, etc., to achieve the effects of more microbial metabolites, significant fertilizer efficiency, and accelerated biological enzymatic hydrolysis and material transformation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A bio-organic fertilizer used to prevent tomato self-poisoning, mainly fermented from the following raw materials: peat 55%, corn meal 20.8%, bran 10%, volcanic stone powder 10%, magnesium sulfate 2%, sulfuric acid Zinc 1%, manganese sulfate 1%, brown sugar 0.1%, fermenting microorganism 0.1%.

[0068] The preparation method of the above-mentioned bio-organic fertilizer for preventing tomato self-poisoning is as follows:

[0069] (1) Activation and expanded cultivation of microbial strains

[0070] Fermentation microorganisms (Bacillus subtilis, Bacillus licheniformis, Rhizopus oryzae, Trichoderma viride) and functional microorganisms (Acinetobacter calcoacetate) are activated according to the following method: the microbial strains preserved by freeze-drying are under aseptic conditions, Clean the ampoule tube with absorbent cotton soaked in 75% alcohol, heat the top of the ampoule with a flame, drop a small amount of sterile water to the heated top to make it rupture...

Embodiment 2

[0111] A kind of bio-organic fertilizer that is used to prevent tomato self-poisoning, different from embodiment 1, the mass ratio of this bio-organic fertilizer is as follows: lignite 45%, corn meal 35%, bran 8.8%, volcanic stone powder 9%, Magnesium sulfate 1%, zinc sulfate 0.5%, manganese sulfate 0.5%, brown sugar 0.1%, microbial strain 0.1%.

[0112] The difference between the preparation method and Example 1 is that the fermentation temperature is 55°C, the fermentation is 12 days in winter, and the single pile of fermentation is 50 tons.

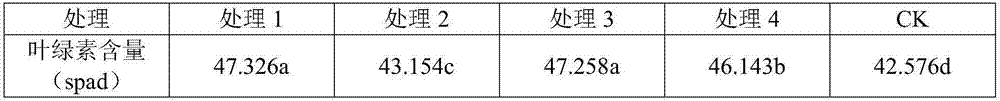

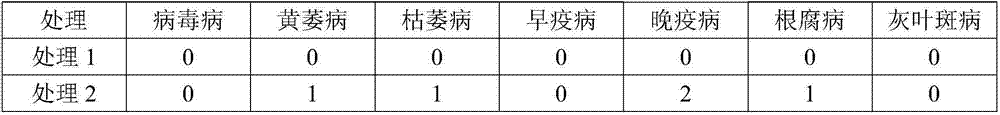

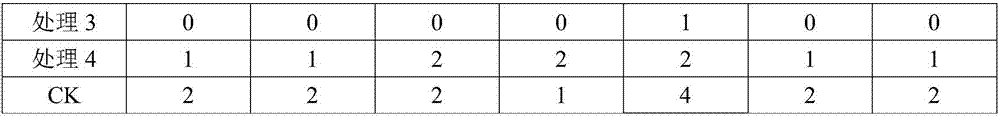

[0113] Add the Acinetobacter calcium acetate culture solution to the fermented organic fertilizer according to the mass ratio of 0.2%, mix evenly, granulate to obtain spherical pellets with a diameter of 3-5mm, and dry them in a drying equipment not higher than 40°C Dry to obtain bio-organic fertilizer. After testing, the results of the bio-organic fertilizer in Example 2 are shown in Table 7.

[0114] Table 7 Example 2 bio-organic f...

Embodiment 3

[0138] A kind of bio-organic fertilizer for preventing tomato self-poisoning, different from embodiment 1, the mass ratio of this bio-organic fertilizer is as follows: 52% of weathered coal, 35% of corn meal, 5% of bran, 5% of volcanic stone powder , magnesium sulfate 1.5%, zinc sulfate 0.5%, manganese sulfate 0.7%, brown sugar 0.1%, microbial strains 0.2%.

[0139] The difference between the preparation method and Example 1 is that the fermentation temperature is 50°C, the summer fermentation is 5 days, and the single pile of fermentation is 40 tons.

[0140] Add the culture solution of Acinetobacter calcium acetate to the fermented organic fertilizer according to the mass ratio of 0.2%, mix evenly, granulate to obtain spherical pellets with a diameter of 3-5mm, and dry them in a drying equipment not higher than 40°C Dry to obtain bio-organic fertilizer. After testing, the results of the bio-organic fertilizer in Example 3 are shown in Table 12.

[0141] Table 12 Example 3 bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com