Lithium ion battery and membrane thereof

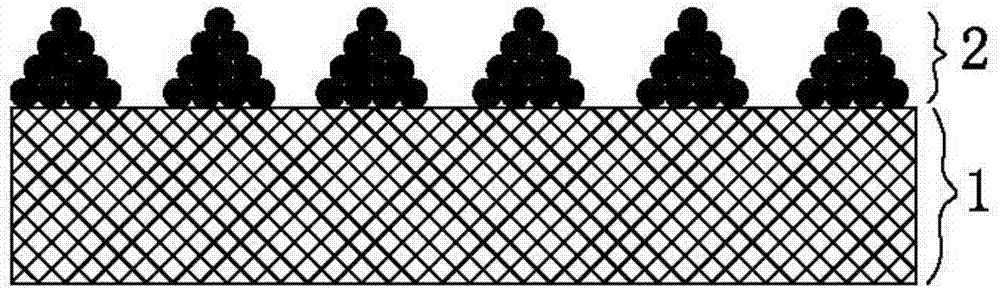

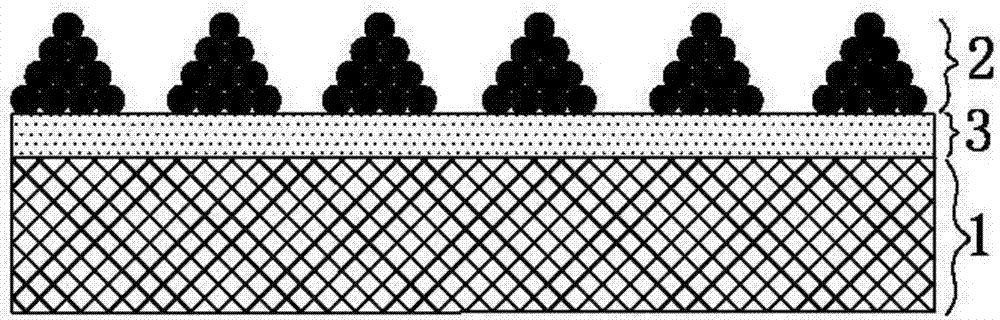

A lithium-ion battery and separator technology, applied in secondary batteries, battery pack parts, secondary battery repair/maintenance, etc., can solve the problem of uncontrollable island and linear distribution, affecting battery electrochemical performance and current density distribution Non-uniformity and other problems, to avoid uneven current density distribution, unaffected electrochemical performance, and uniform current density distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Preparation of positive electrode sheet:

[0052] Lithium cobaltate, conductive agent superconducting carbon (Super-P), and binder polyvinylidene fluoride (PVDF) were mixed uniformly at a mass ratio of 97:1.5:1.5 to make a lithium-ion battery cathode slurry with a certain viscosity. The slurry is coated on the aluminum foil of the current collector, and then cold pressed after drying at 85°C; then edge trimming, cutting, and slitting are performed, and after slitting, dry at 110°C for 4 hours under vacuum conditions, and weld the tabs. Made into lithium-ion battery cathode sheet.

[0053] Preparation of negative electrode sheet:

[0054] Make a slurry of graphite and conductive agent superconducting carbon (Super-P), thickener sodium carboxymethyl cellulose (CMC), and binder styrene-butadiene rubber (SBR) at a mass ratio of 96:2.0:1.0:1.0 , coated on the current collector copper foil and dried at 85°C, trimmed, cut into pieces, slitting, and dried at 110°C for 4 hours...

Embodiment 2

[0060] The difference between this embodiment and Example 1 is the preparation of diaphragm:

[0061] 1) Take a polypropylene microporous membrane with a thickness of 16 μm as the base membrane;

[0062] 2) Stir polyoxyethylene and styrene-butadiene in N-methylpyrrolidone first, the mass ratio of polyoxyethylene and styrene-butadiene is 92:8, add calcium carbonate after stirring for 2 hours, poly The mass ratio of ethylene oxide to calcium carbonate is 50:50, continue to stir for 1 hour to obtain a slurry, the solid content of the slurry is 20%, and then use dip coating to evenly coat the slurry prepared above on both sides of the base film , after drying, a polymer-coated diaphragm was obtained. The coating thickness on each side was 4 μm, and then the diaphragm was soaked in 0.5M hydrochloric acid for 30 minutes, and baked in an oven at 60 ° C for 2 hours to form an island-shaped uniform Distributed polymer coating, the area of the polymer coating is 90% of the area of ...

Embodiment 3

[0065] The difference between this embodiment and Example 1 is the preparation of diaphragm:

[0066] 1) Take a polypropylene / polyethylene / polypropylene three-layer composite microporous membrane with a thickness of 20 μm as the base membrane;

[0067] 2) Stir polymethyl methacrylate and styrene-butadiene in deionized water first, the mass ratio of polymethacrylate to styrene-butadiene is 94:6, stir for 2 hours and then add chlorinated Ammonium, the mass ratio of polymethyl methacrylate and ammonium chloride is 50:50, continue to stir for 1h to obtain a slurry, the solid content of the slurry is 40%, and then use a touch-up to coat the slurry prepared above evenly Cover one side of the base film with a coating thickness of 3 μm, and bake the coated diaphragm in an oven at 80°C for 6 hours to form a polymer coating evenly distributed in an island shape. The area of the polymer coating is the base 30% of the membrane area, and then the diaphragm is cut and cut into pieces.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com