Method for recycling ammonia nitrogen, phosphorus and volatile fatty acid in livestock-poultry excrement hydrolysate by two-stage bipolar membrane electrodialysis

A technology of bipolar membrane electrodialysis and livestock and poultry manure, applied in chemical instruments and methods, separation methods, animal husbandry wastewater treatment, etc., can solve the problem of lowering current efficiency, bipolar membrane electrodialysis cannot achieve separation, product purity decline, etc. problems, to achieve the effect of improving recovery efficiency, improving current efficiency and ammonia nitrogen recovery, and increasing recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

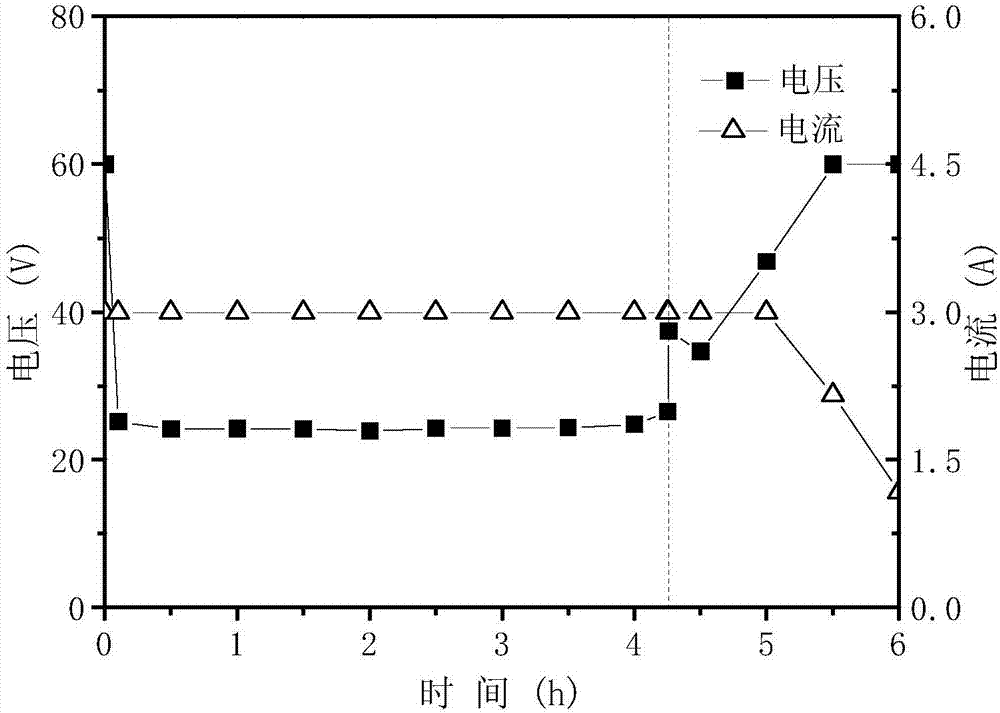

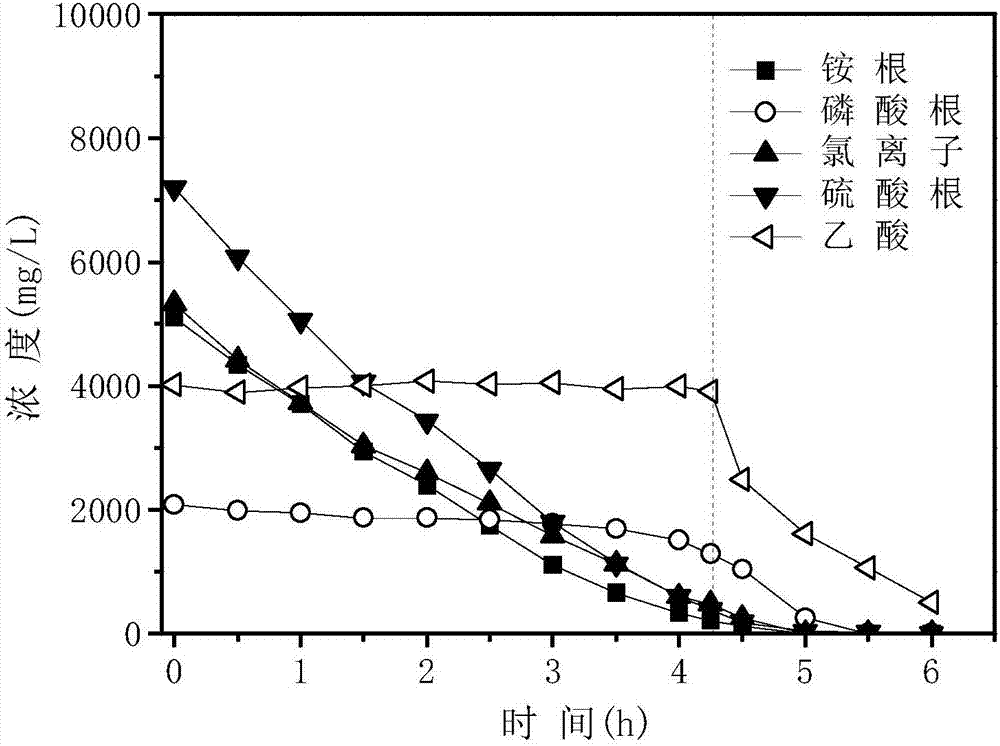

[0040] Example 1: Two-stage bipolar membrane electrodialysis treatment of artificially synthesized pig manure hydrolyzate.

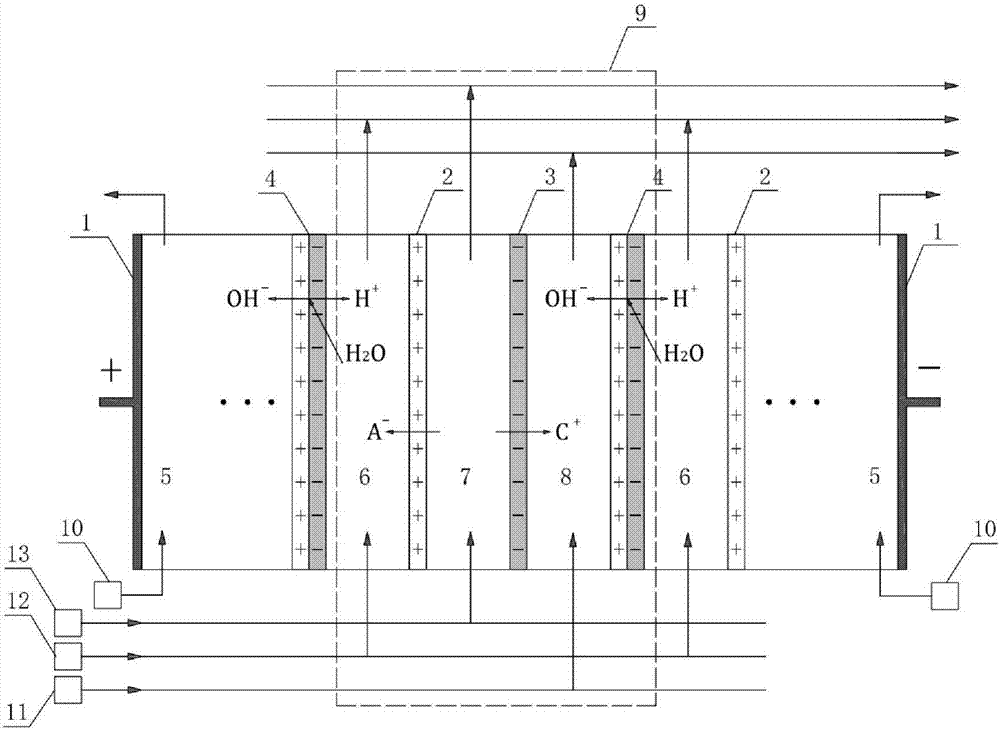

[0041] The electrodialysis membrane stack used in this example is as figure 1 As shown, the anion and cation exchange membranes and bipolar membranes used are heterogeneous ion exchange membranes produced by Czech MemBrain company, and the effective area of each membrane in the membrane stack is 200cm 2 , there are 5 membrane compartment repeating units.

[0042] Add 5L of artificially synthesized pig manure hydrolyzate into the salt chamber, adjust its pH to 5 with nitric acid and sodium hydroxide, and its composition is shown in Table 1; add 1L of deionized water to the alkali chamber and acid chamber respectively; Add 1L sodium sulfate solution, the concentration is 0.1mol / L. The inlets and outlets of the salt chamber, alkali chamber, acid chamber and electrode chamber of the membrane stack are connected to their respective solution tanks with sil...

Embodiment 2

[0048] Example 2: The actual pig manure hydrolyzate was treated by bipolar membrane electrodialysis.

[0049] This example is to illustrate that the actual pig manure hydrolyzate conforms to the two-stage ion removal rule, and the reflux of the acid solution can improve the phosphorus concentration and separation efficiency. The experimental device used is the same as that described in Example 1, except that 1 L of pretreated pig manure hydrolyzate is housed in the salt chamber.

[0050] The pig manure hydrolyzate is taken from the septic tank of the pig house. Before the pig manure hydrolyzate is taken, the pig manure has undergone preliminary hydrolysis in the septic tank for at least two weeks. Add hydrochloric acid to the pig manure hydrolyzate to adjust the pH value to 5, settle for 24 hours, remove scum and foam; take the supernatant and centrifuge it at a low speed of 3000rpm, then centrifuge it at a high speed of 10000rpm, filter it through ordinary filter paper, and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com