Aerobic biological filler and arrangement method thereof

A technology of aerobic biology and layout method, which is applied in sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc. Low preparation cost, avoidance of biological filler accumulation, and good biological performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

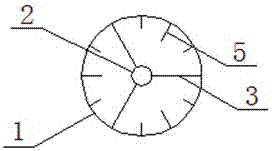

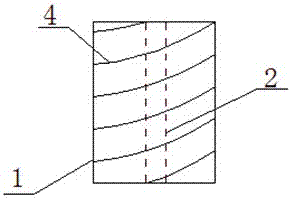

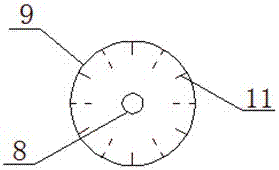

[0024] Specific implementation mode one: as figure 1 and figure 2 As shown, what is described in this embodiment is an aerobic biological filler. The filler is prepared from polyethylene-chitosan derivatives. The filler consists of a hollow tube 1 and a solid cylinder 2 concentric with it. The hollow tube 1 and the solid cylinder 2 are connected by three brackets 3 at 120° each other, the outer diameter of the hollow tube 1 is 30-50 mm, the height of the hollow tube 1 is 40-50 mm, and the hollow tube 1 is 40-50 mm in height. 1. The wall thickness is 1.0~1.5mm, and the diameter of the solid cylinder 2 is 5.0~10.0mm; the outer peripheral surface of the hollow tube 1 is provided with a plurality of spiral grooves 4 parallel to the axial direction, and each adjacent two The distance between each of the spiral grooves 4 is 8.0~10.0mm, the depth of each spiral groove 4 is 1.5mm, and the width of each spiral groove 4 is 1.0~2.0mm; the hollow circular tube 1. A plurality of protrud...

specific Embodiment approach 2

[0025] Specific embodiment two: a kind of aerobic biological filler described in specific embodiment one, the specific surface area of described filler is 800~950m 2 / m 3 .

specific Embodiment approach 3

[0026] Specific implementation mode three: as Figure 5 As shown, a method for arranging the aerobic biological filler in the aeration tank described in Embodiment 1 or 2, the specific steps of the method are as follows:

[0027] Get many nylon ropes 6 with high acid and alkali corrosion resistance and toughness, string a plurality of said fillers to each nylon rope 6 one by one, tie a knot every 60mm on each nylon rope 6, so that each filler can Fix between the two nodes of the nylon rope 6, control the length of each nylon rope 6 at 4.0m; weld the square frame 7 with acid and alkali corrosion-resistant stainless steel, and evenly fix the stringed packing on the square frame 7 Aeration tubes are tiled at the bottom of the aeration tank, and the water body is aerated by an air compressor; the bottom of the cube frame 7 that is evenly fixed with a plurality of fillers is arranged at 50 cm above the aeration tubes, and the upper part makes the fillers between the water surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com