Preparation and application of NiWP electric catalyst material with three-dimensional structure

An electrocatalyst and three-dimensional structure technology, applied in the direction of physical/chemical process catalyst, electrode, electrolysis process, etc., can solve the problems of limiting large-scale application, poor catalytic performance, and scarce crustal reserves, etc., to achieve low energy consumption and low price The effect of stability and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

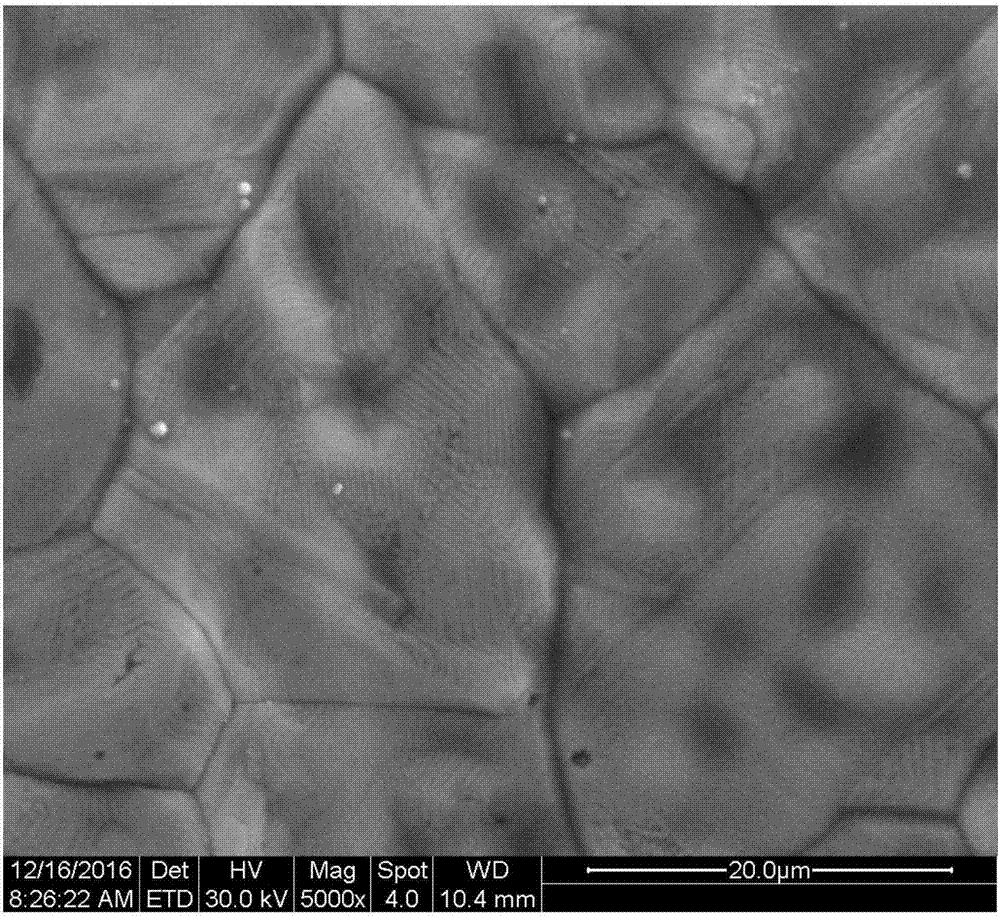

[0045] Example 1: prepare according to the composition of the plating solution in Table 1, the substrate is nickel foam, adjust the electrodeposition time to 20 minutes, and then electrodeposit ternary metal phosphide according to the above process steps.

[0046] Table 1 specific implementation conditions

[0047]

Embodiment 2

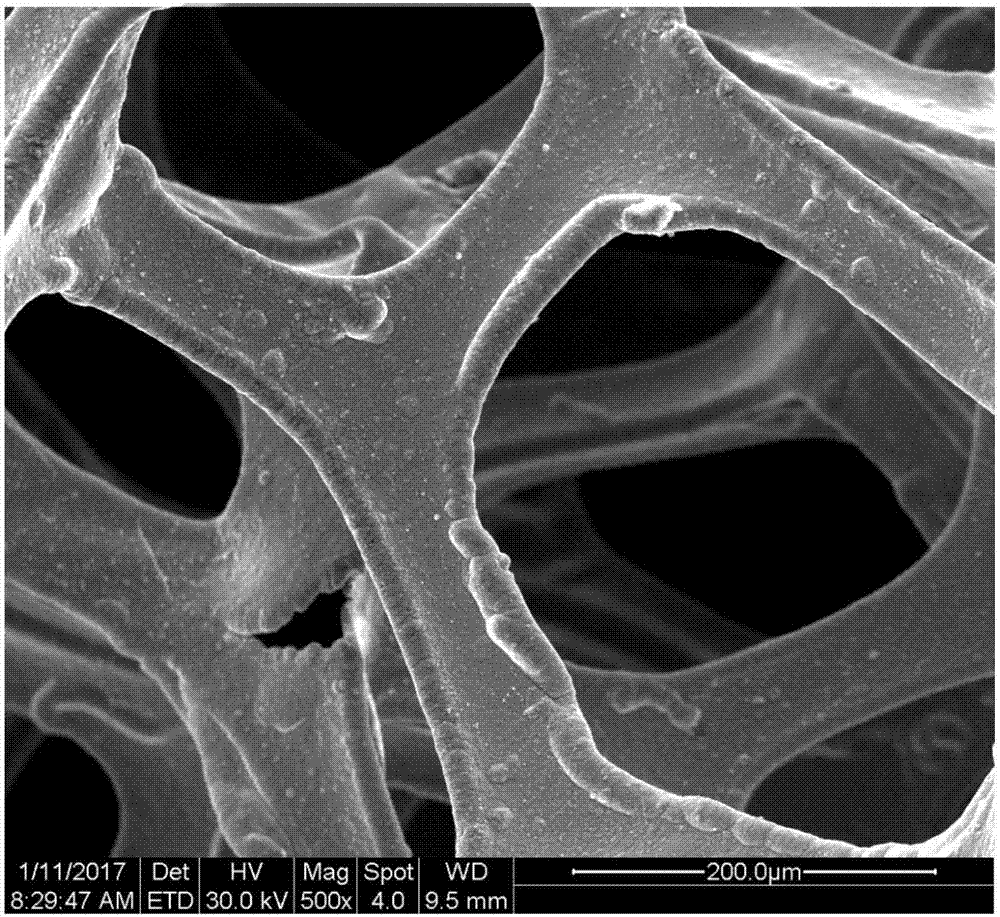

[0048] Embodiment 2: prepare according to the composition of the plating solution in Table 2, the substrate is copper foam, adjust the electrodeposition time to 20 minutes, and then electrodeposit ternary metal phosphide according to the above process steps.

[0049] Table 2 specific implementation conditions

[0050]

[0051]

Embodiment 3

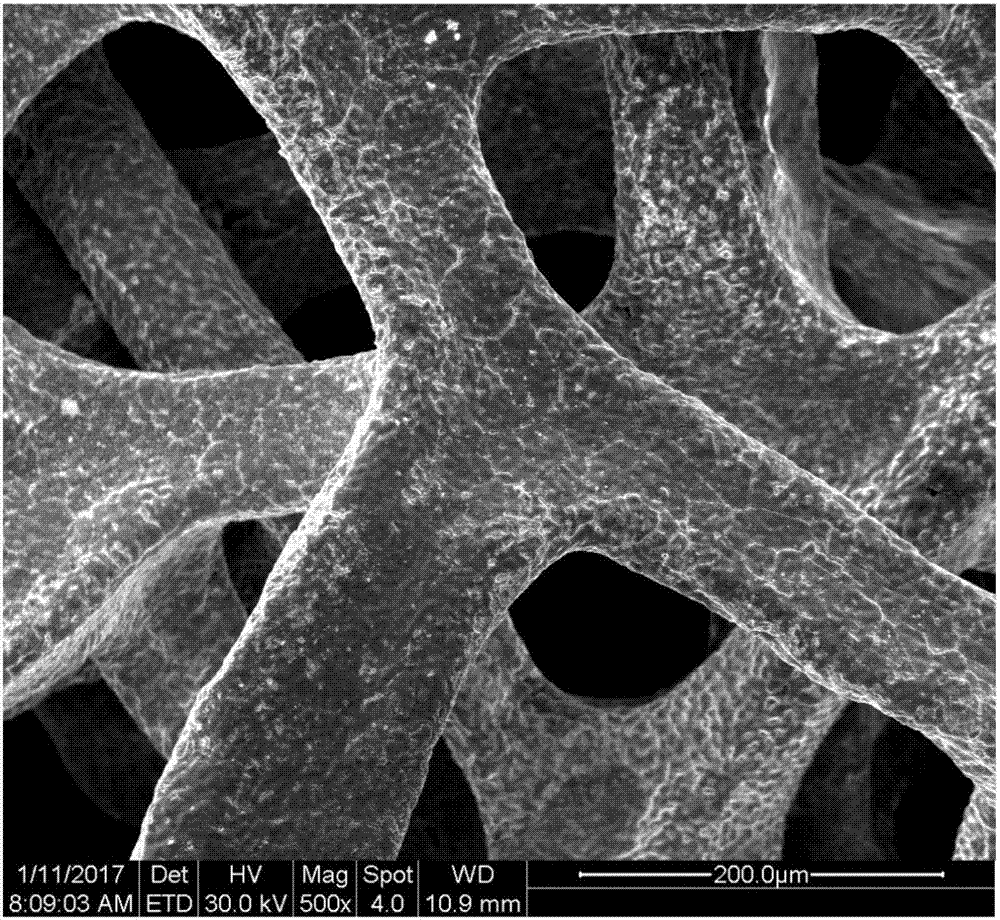

[0052] Example 3: prepare according to the composition of the plating solution in Table 3, the substrate is nickel foam, adjust the electrodeposition time to 10 minutes, and then electrodeposit ternary metal phosphide according to the above process steps.

[0053] Table 3 specific implementation conditions

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com