Waterborne flame-retardant antirust paint and preparation method thereof

An anti-rust paint, water-based technology, used in anti-corrosion coatings, fire-resistant coatings, coatings, etc., can solve the problems of paint performance decline, large addition amount, no research reports, etc., to improve drying speed, improve adhesion, reduce The effect of flame retardant dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

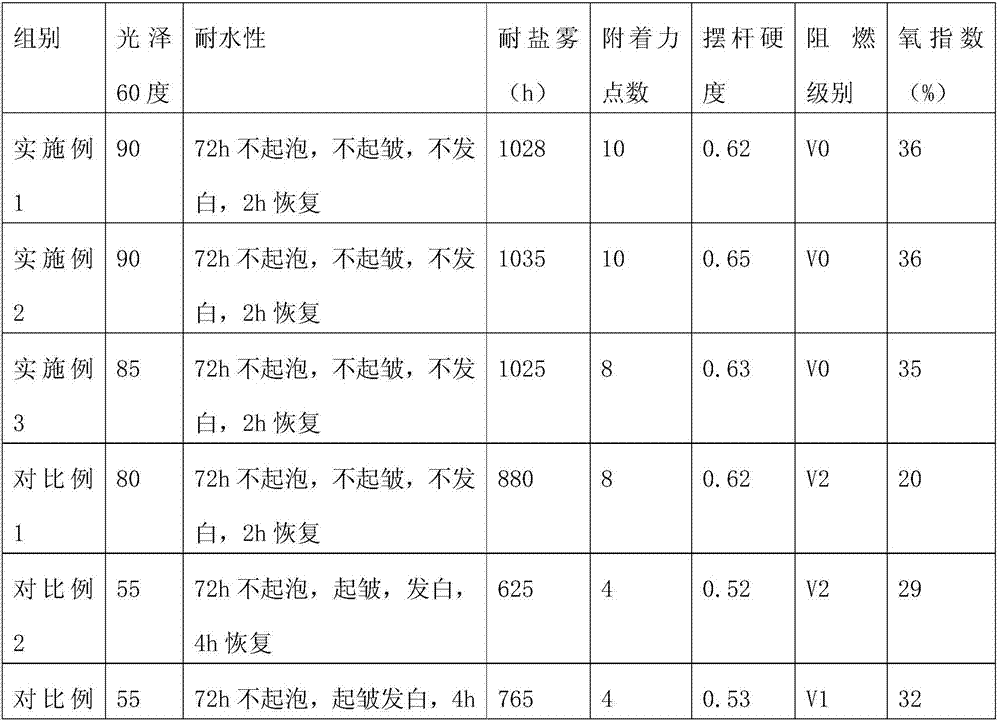

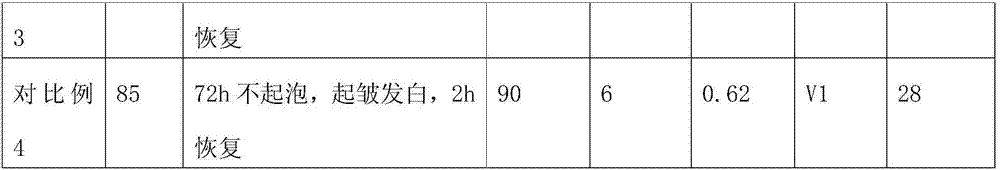

Embodiment 1

[0028] A water-based flame-retardant anti-rust paint is made of the following raw materials in parts by weight: 30 parts of acrylic modified alkyd resin emulsion, 20 parts of rosin phenolic resin, 5 parts of epoxy resin, 11 parts of styrene-acrylic emulsion, and 20 parts of water , 18 parts of flame retardant, 0.2 parts of anionic alkyl succinate sodium, 0.2 parts of silanol wetting agent, 1 part of sodium bentonite, 1 part of rust inhibitor, 2 parts of toluene diisocyanate curing agent, 2 parts of pH regulator 0.6 part of amino-2-methyl-1-propanol, 0.2 part of polyether polysiloxane copolymer of defoaming agent, 0.2 part of leveling agent, and 3 parts of cosolvent; the leveling agent is modified polyacrylate The solution leveling agent and polysiloxane-polyether copolymer leveling agent are mixed at a weight ratio of 1:2; the co-solvent is formed by mixing p-aminobenzoic acid and propylene glycol phenyl ether at a weight ratio of 1:2. The flame retardant is magnesium aluminum...

Embodiment 2

[0034] A water-based flame-retardant antirust paint is made of the following raw materials in parts by weight: 35 parts of acrylic modified alkyd resin emulsion, 22 parts of rosin phenolic resin, 6 parts of epoxy resin, 12 parts of styrene-acrylic emulsion, and 25 parts of water , 22 parts of flame retardant, 0.3 parts of anionic alkyl succinate sodium, 0.3 parts of silanol wetting agent, 2 parts of sodium bentonite, 1.2 parts of rust inhibitor, 2 parts of diphenylmethane diisocyanate curing agent, pH adjustment Agent 2-amino-2-methyl-1-propanol 0.7 parts, defoamer polyether polysiloxane copolymer 0.4 parts, leveling agent 0.25 parts, cosolvent 3.5 parts; leveling agent is modified polyacrylic acid Ester solution leveling agent and polysiloxane-polyether copolymer leveling agent are mixed at a weight ratio of 1:2; co-solvents are mixed with p-aminobenzoic acid and propylene glycol phenyl ether at a weight ratio of 1:2. The flame retardant is magnesium aluminum hydrotalcite pow...

Embodiment 3

[0040] A water-based flame-retardant anti-rust paint is made of the following raw materials in parts by weight: 40 parts of acrylic modified alkyd resin emulsion, 25 parts of rosin phenolic resin, 8 parts of epoxy resin, 15 parts of styrene-acrylic emulsion, and 30 parts of water , 25 parts of flame retardant, 0.4 parts of anionic alkyl succinate sodium, 0.4 parts of silanol wetting agent, 3 parts of sodium bentonite, 1.5 parts of rust inhibitor, 3 parts of mixed polyisocyanate XD803 curing agent, pH adjustment Agent 2-amino-2-methyl-1-propanol 0.75 parts, defoamer polyether polysiloxane copolymer 0.6 parts, leveling agent 0.3 parts, cosolvent 4 parts; leveling agent is modified polyacrylic acid Ester solution leveling agent and polysiloxane-polyether copolymer leveling agent are mixed at a weight ratio of 1:2; co-solvents are mixed with p-aminobenzoic acid and propylene glycol phenyl ether at a weight ratio of 1:2. The flame retardant is magnesium aluminum hydrotalcite powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com