Method for directly producing sodium citrate, potassium citrate and ammonium citrate from citric acid fermentation broth by melamine compound salt crystallization

A technology of citric acid fermentation broth and sodium citrate, which is applied in carboxylate preparation, separation/purification of carboxylic acid compounds, organic chemistry, etc., and can solve the problems of high cost and low yield of citric acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

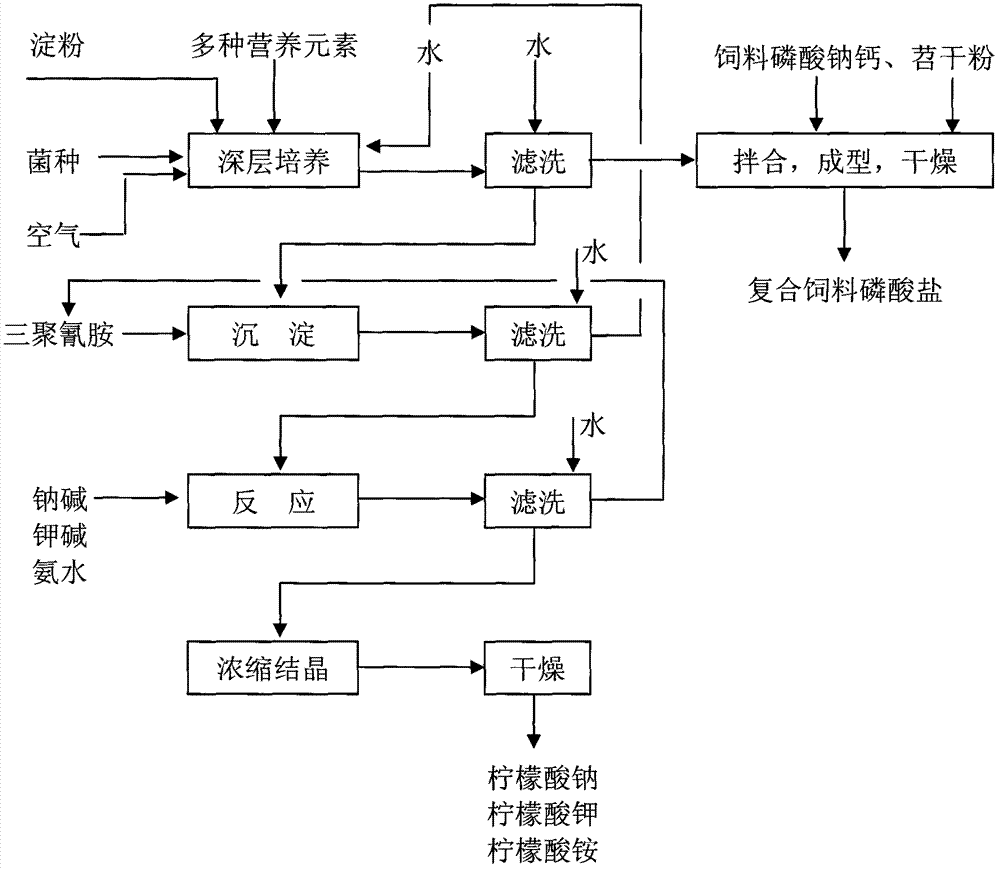

Image

Examples

Embodiment 1

[0012] Take some fermentation slurry from the fermentation workshop of a domestic citric acid factory, press and filter, take 100 grams of mycelia, mix with 20 grams of sweet potato dry powder and 20 grams of feed sodium calcium phosphate, and extrude into granular form at 85-95 degrees Celsius Dried, ready-made compound feed sodium-calcium phosphate, get 1000 grams of fermented liquid that filters mycelium, measure citric acid content and be 17.8%, add the industrial melamine 238 grams that purity is 98%, stir 1 hour at 25 degrees centigrade, pump Filtration, rinsing, return of filtrate and washing water for the submerged culture of sweet potato dry powder, add 25% sodium hydroxide solution to the wet solid phase, adjust to the amount of trisodium salt, stir for half an hour, suction filter and wash, wet The solid phase is regenerated melamine, which is returned to extract the citric acid in the next cycle of fermentation broth, the filtrate and washing water are concentrated,...

Embodiment 2

[0014] Take 1000 grams of the fermented liquid filtered above, add 238 grams of industrial melamine with a purity of 98%, stir for 1 hour at 25 degrees Celsius, filter with suction, rinse, and return the filtrate and washing water for the submerged culture of sweet potato dry powder, wet solid phase Add potassium hydroxide with a concentration of 25%, adjust to the amount of tripotassium salt, stir at 25 degrees Celsius for half an hour, filter with suction, rinse, the wet solid phase is regenerated melamine, return to extract the lemon in the fermentation broth The acid, filtrate and washing water were concentrated, crystallized, separated, and dried at 100-110 degrees Celsius to obtain 275 grams of anhydrous potassium citrate with a purity of 98.1%. It was learned that the national standard would not be promulgated until several months later, and currently it can only be used by root users The required quality is manufactured. Since this process does not add chemical raw mate...

Embodiment 3

[0016] Take 1000 grams of the above-filtered fermented liquid, add 238 grams of melamine with a purity of 98%, stir for 1 hour at 26 degrees Celsius, filter with suction, wash, and return the filtrate and washing water to the submerged cultivation of sweet potato dry powder, and add concentration to the wet solid phase It is 25% ammonia water, adjusted to the amount of triammonium salt generated, stirred at 26 degrees Celsius for half an hour, filtered, washed, and the wet solid phase is returned to extract citric acid in the fermentation broth, the filtrate and washing water are concentrated, crystallized, separated, Dried at 100-110 degree Celsius to obtain 218 grams of ammonium citrate with a purity of 98.2%.

[0017] Table 1, trisodium citrate anhydrous analysis, weight (%)

[0018] standard name BP2000 This craft product content ≥99% 99.3% acidity and alkalinity meet the requirements meet the requirements Sulfate ≤0.03% 0% Heavy m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com