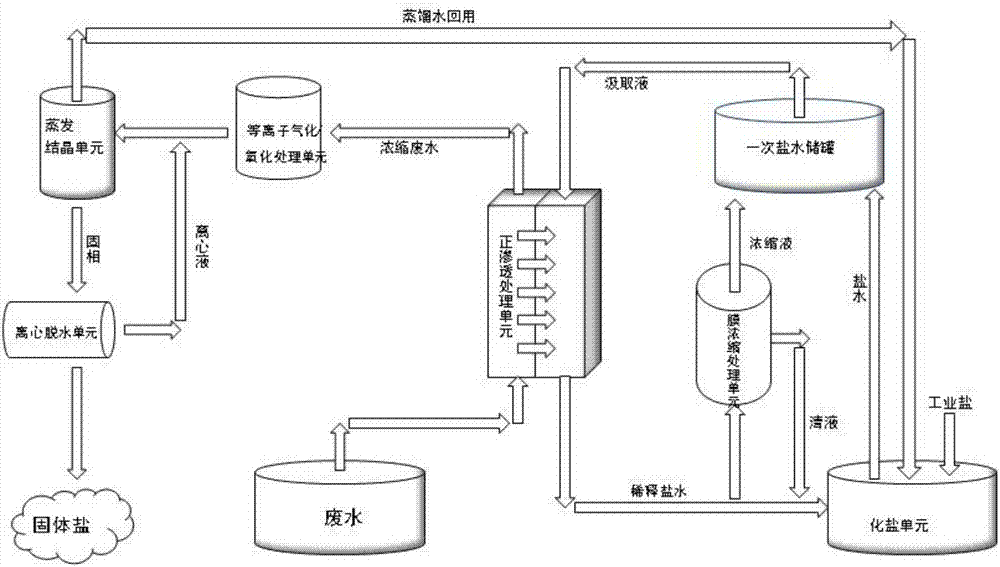

Chlorine-alkali wastewater forward osmosis treatment system and treatment process

A treatment system and treatment process technology, applied in the field of environmental protection water treatment, can solve the problems of increasing the operating cost of the forward osmosis process, affecting the production and working environment, and unsuitable for reuse of clean water, so as to save configuration and regeneration costs and reduce operating costs. , The effect of strong anti-organic fouling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

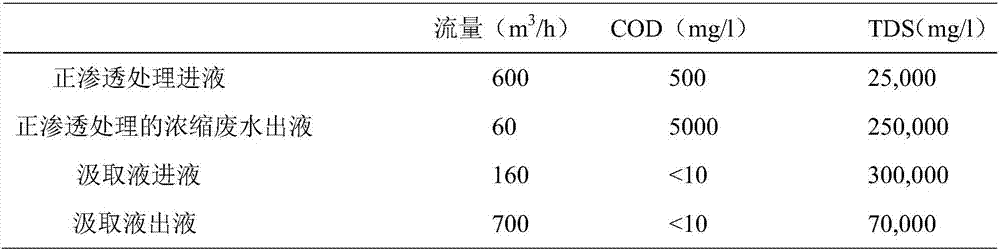

[0040] The chlor-alkali wastewater produced by a certain chlor-alkali plant is treated with the above-mentioned treatment system and process of the present invention, wherein the primary TDS concentration of the wastewater is about 300,000 ppm, and the COD concentration is 1,200 ppm. The water quality before and after treatment at each main treatment point is shown in Table 1:

[0041] Table 1 Wastewater treatment data

[0042]

[0043] From the wastewater treatment data in Table 1, it can be seen that after the wastewater is biochemically treated (that is, the influent of the forward osmosis treatment), its COD can be reduced to 500 mg / l, and TDS can be reduced to 25,000 mg / l. After the forward osmosis treatment, the TDS of the wastewater was concentrated to 250,000 ppm, and at the same time, the concentration of the draw solution (sodium chloride solution) was diluted from 300,000 ppm to 70,000 ppm. The forward osmosis membrane module has a high rejection rate of organic matter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com