A kind of preparation method of nanometer sio2/starch-based composite adhesive

A composite adhesive and starch-based technology, applied in starch adhesives, adhesive types, adhesive additives, etc., can solve problems such as high starch viscosity and reduce system viscosity, simplify the preparation process, reduce viscosity, and save energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

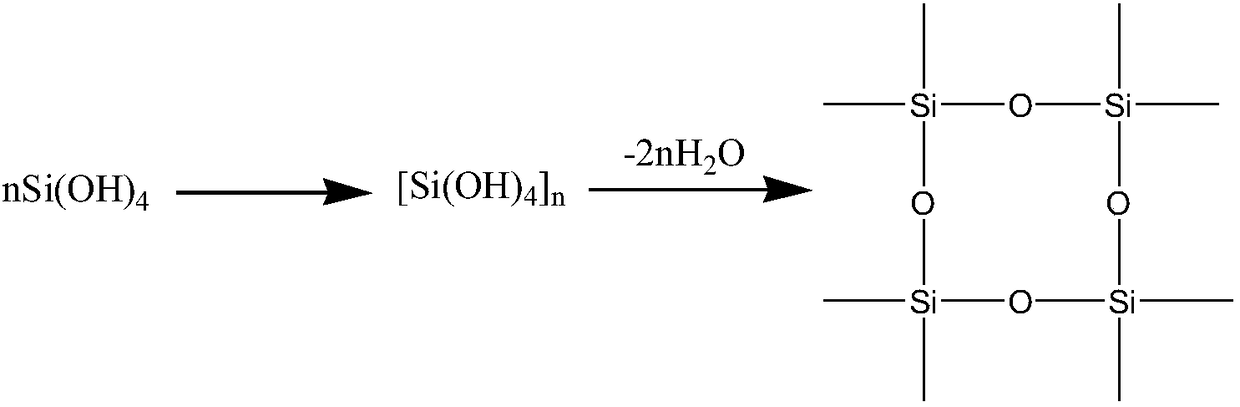

Method used

Image

Examples

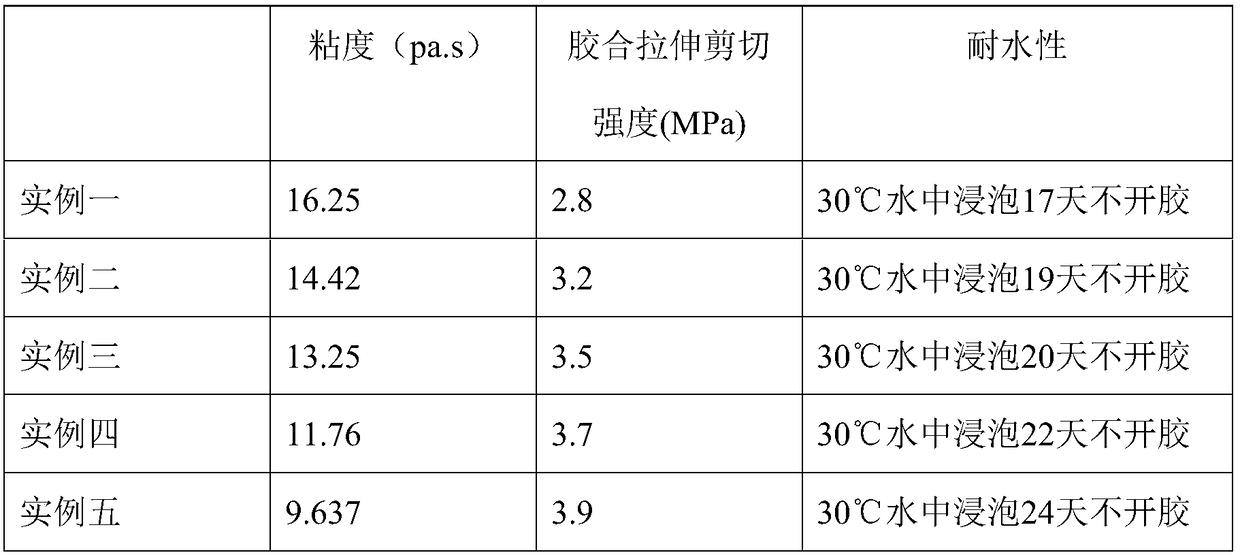

Embodiment 1

[0027] 1. Preparation of sodium silicate gelatinized starch for sodium silicate: After mixing liquid sodium hydroxide with a concentration of 10wt% and quartz sand uniformly at a mass ratio of 1:1, add a concentration of 15% that accounts for 40% of the liquid sodium hydroxide mass After the starch solution was heated to 100 °C under high pressure, the stirring reaction continued for 80 min, and SiO, which accounted for 16% of the liquid sodium hydroxide mass, was added. 2 , the water glass sodium silicate gelatinized starch emulsion can be prepared;

[0028] 2. Preparation of starch adhesive: Add additives such as 1% plasticizer glycerol, 0.2% crosslinking agent borax, 0.3% defoamer tributyl phosphate, 0.5 % of the emulsifier sodium lauryl sulfate, etc., nano-SiO can be obtained after continuous stirring at 60 ° C for 30 min 2 / Starch-based composite adhesive.

Embodiment 2

[0030] 1. Preparation of sodium silicate gelatinized starch for sodium silicate: After mixing liquid sodium hydroxide with a concentration of 12wt% and quartz sand uniformly at a mass ratio of 1:2, add 18% liquid sodium hydroxide with a mass ratio of 45% The concentration of starch solution was heated to 110 ° C under high pressure, and the stirring reaction continued for 90 min, and SiO, which accounted for 18% of the liquid sodium hydroxide mass, was added. 2 , the water glass sodium silicate gelatinized starch emulsion can be prepared;

[0031] 2. Preparation of starch adhesive: Add auxiliaries such as 2% plasticizer urea, 0.3% crosslinking agent toluene diisocyanate, 0.4% defoamer polydimethyl methacrylate to the prepared sodium silicate gelatinized starch emulsion. Siloxane, 1% emulsifier sodium dodecyl benzene sulfonate, etc., nano-SiO can be obtained after continuous stirring at 65 ° C for 30 min 2 / Starch-based composite adhesive.

Embodiment 3

[0033] 1. Preparation of sodium silicate gelatinized starch for sodium silicate: After mixing liquid sodium hydroxide with a concentration of 14wt% and quartz sand uniformly at a mass ratio of 1:3, add a concentration of 21% that accounts for 50% of the liquid sodium hydroxide mass After the starch solution was heated to 120 °C under high pressure, the stirring reaction continued for 100 min, and SiO2, which accounted for 20% of the liquid sodium hydroxide mass, was added. 2 , the water glass sodium silicate gelatinized starch emulsion can be prepared;

[0034] 2. Preparation of starch adhesive: Add additives such as 3% plasticizer phthalate diester, 0.4% crosslinking agent trimethylol phenol, 0.5% Defoamer polyoxyethylene polyoxypropanolamine ether, 1.5% emulsifier OP-10, etc., nano-SiO can be obtained after continuous stirring at 70 ° C for 30 min 2 / Starch-based composite adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com