Partially hydrolyzed whey protein powder and preparation method thereof

A whey protein powder, whey protein technology, applied in the direction of protein food processing, animal protein processing, protein food ingredients, etc. Comprehensive evaluation and other issues to achieve the effect of facilitating digestion and absorption, reducing the probability of allergic reactions, and avoiding protein denaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Partially hydrolyzed whey protein powder, obtained by the following preparation method:

[0031]Prepare concentrated whey protein into whey protein aqueous solution with a mass concentration of 5%, and keep the solution at 60°C for 10 minutes to denature the protein, then cool to 55°C; add to the cooled whey protein aqueous solution Compound protease, this compound protease (neutral protease F (Validase FP Concentrate) and neutral protease G ( The ratio of Protease GBW) is 5:1) and the mass ratio of whey protein substrate is 0.4:100, and it is hydrolyzed while stirring at 55°C for 4 hours, and then the pH value of the solution is adjusted to 6.75- 6.85, heat the above solution at 80°C for 10 minutes to inactivate the protease, and then quickly cool down to room temperature; conduct nanofiltration concentration at room temperature, feed flow rate 1-3t / h, feed pressure 6-12bar, membrane pass The volume is 50-400L / h, and the solid content after concentration is 25%-35%. ...

Embodiment 2

[0040] Partially hydrolyzed whey protein powder, obtained by the following preparation method:

[0041] The difference from Example 1 is that the concentrated whey protein is prepared into a whey protein aqueous solution with a mass concentration of 10%, and the solution is incubated at 85°C for 5 minutes to denature the protein, and then cooled to 50°C; The mass ratio of the compound protease (the ratio of neutral protease F and neutral protease G is 5:1) to the substrate whey protein is 0.6:100, and it is hydrolyzed at 50°C for 2 hours; it is heated at 85°C for 8min to make Protease inactivation.

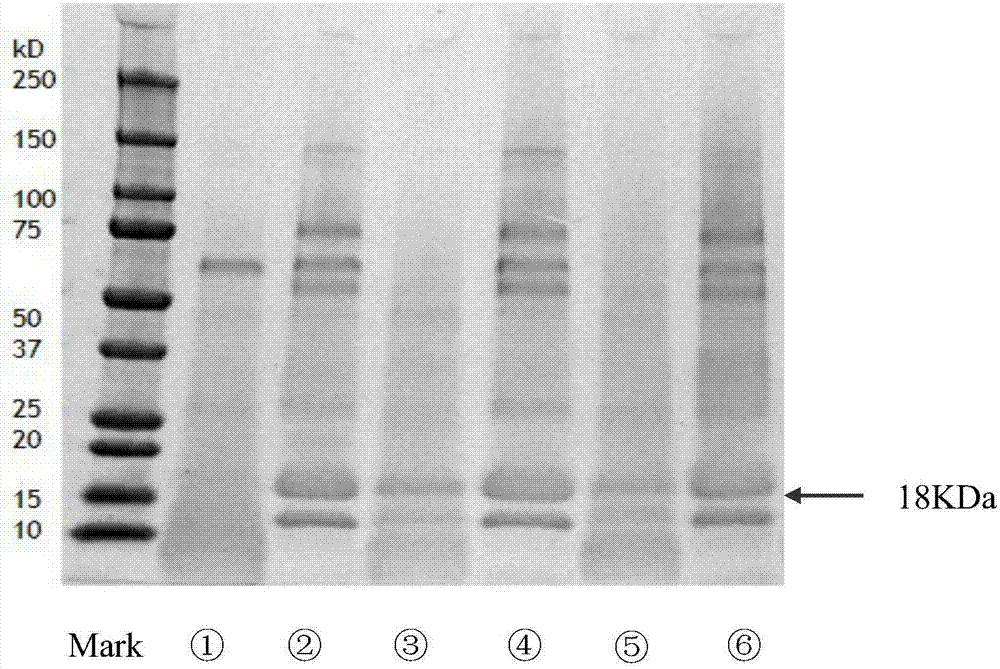

[0042] In addition, in this example, the β-lactoglobulin hydrolysis rate of the prepared partially hydrolyzed whey protein powder was tested. Detection method: SDS-dextran gel electrophoresis is used to detect the hydrolysis of β-lactoglobulin in the hydrolyzate. For specific detection results, see figure 1 Middle ⑤ and ⑥ strips. The hydrolysis rate of β-lactoglobulin was 73%. ...

Embodiment 3

[0044] Partially hydrolyzed whey protein powder, obtained by the following preparation method:

[0045] The difference from Example 1 is that the concentrated whey protein is prepared into an aqueous whey protein solution with a mass concentration of 8%, and the solution is incubated at 80°C for 8 minutes to denature the protein, and then cooled to 55°C; Compound protease (neutral protease F (Validase FP Concentrate) and neutral protease P ( The mass ratio of PPU 95000) was 6:1) to the substrate whey protein was 0.7:100, hydrolyzed at 55°C for 3 hours; heated at 90°C for 5min to inactivate the protease.

[0046] In addition, in this example, the bitterness and sensory properties of the prepared partially hydrolyzed whey protein powder were tested. Detection method: evaluation of bitterness, the caffeine is formulated to concentrations of 0, 0.025%, 0.05%, 0.1%, 0.2%, and 0.3%, respectively, and the corresponding score and degree of bitterness are 1-no bitterness, 2-slight B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com