A method for growing gete alloy film by thermal atomic layer deposition

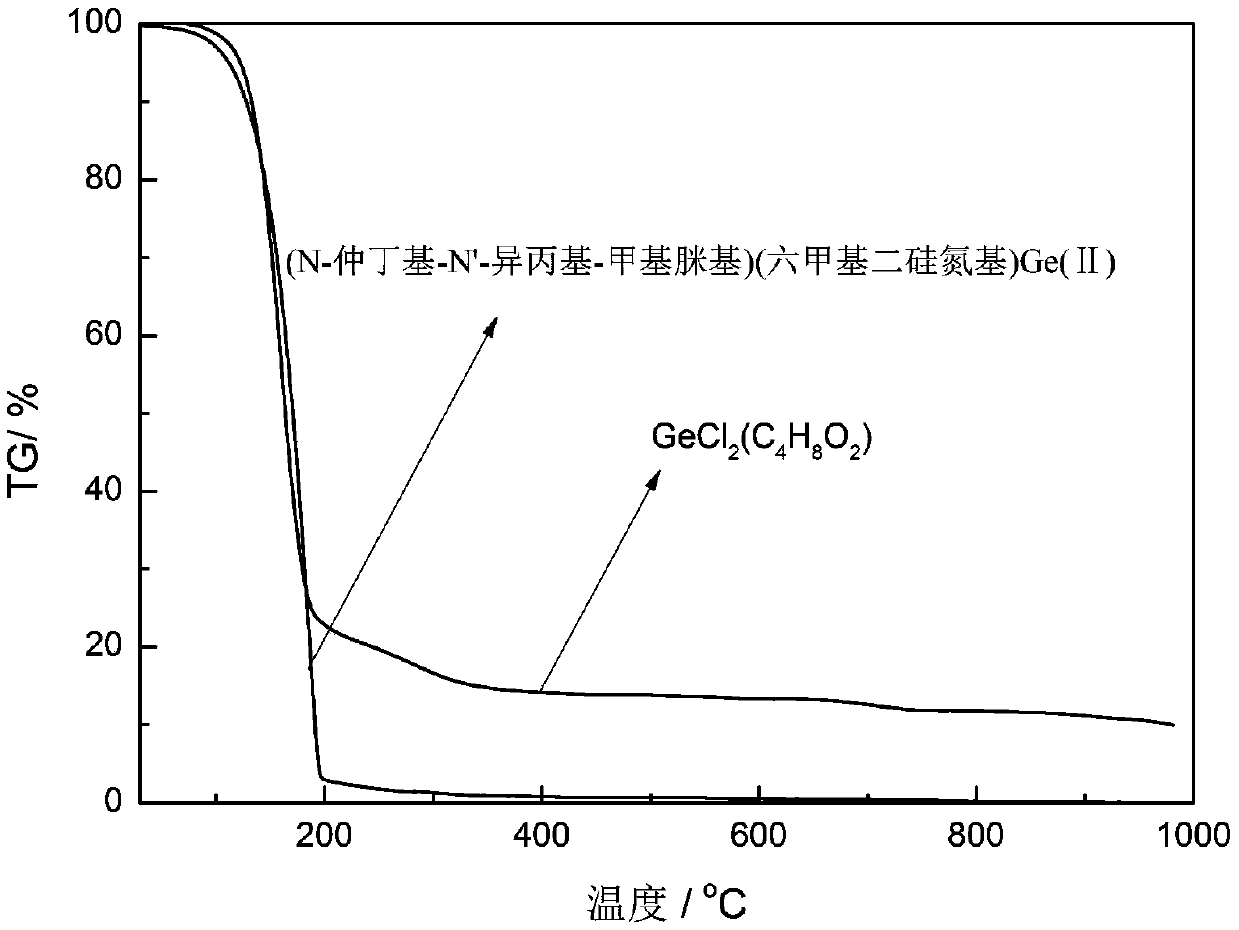

An alloy thin film and thermal atom technology, applied in coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of poor thermal stability of precursors, limited application, poor thermal stability, etc., to improve chemical reactivity. , Easy to store and transport, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

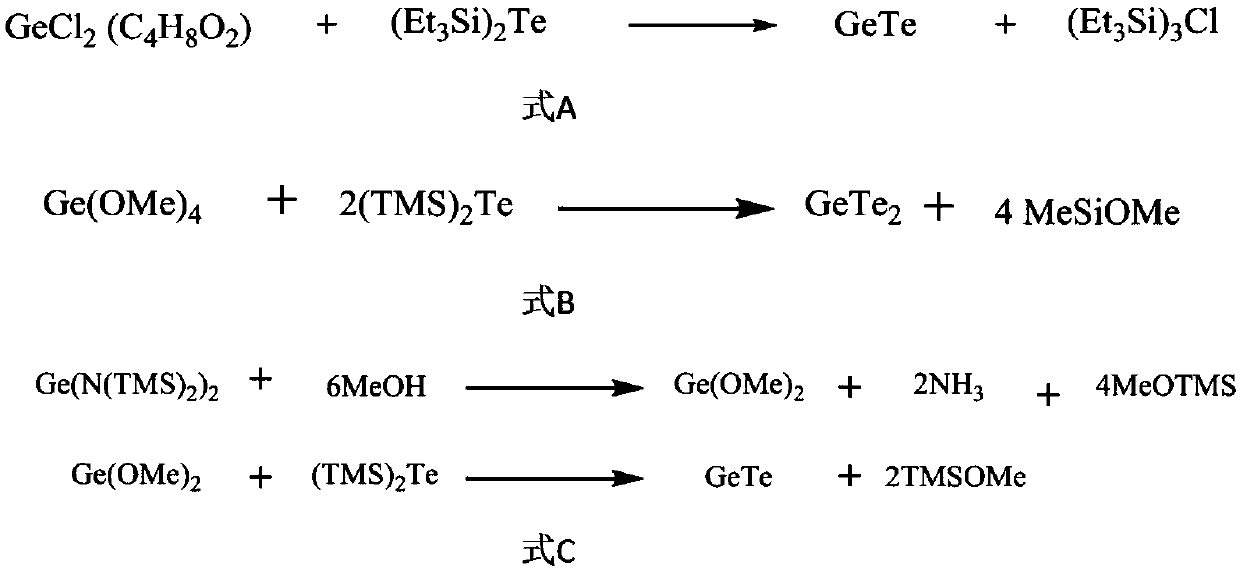

Method used

Image

Examples

Embodiment 1

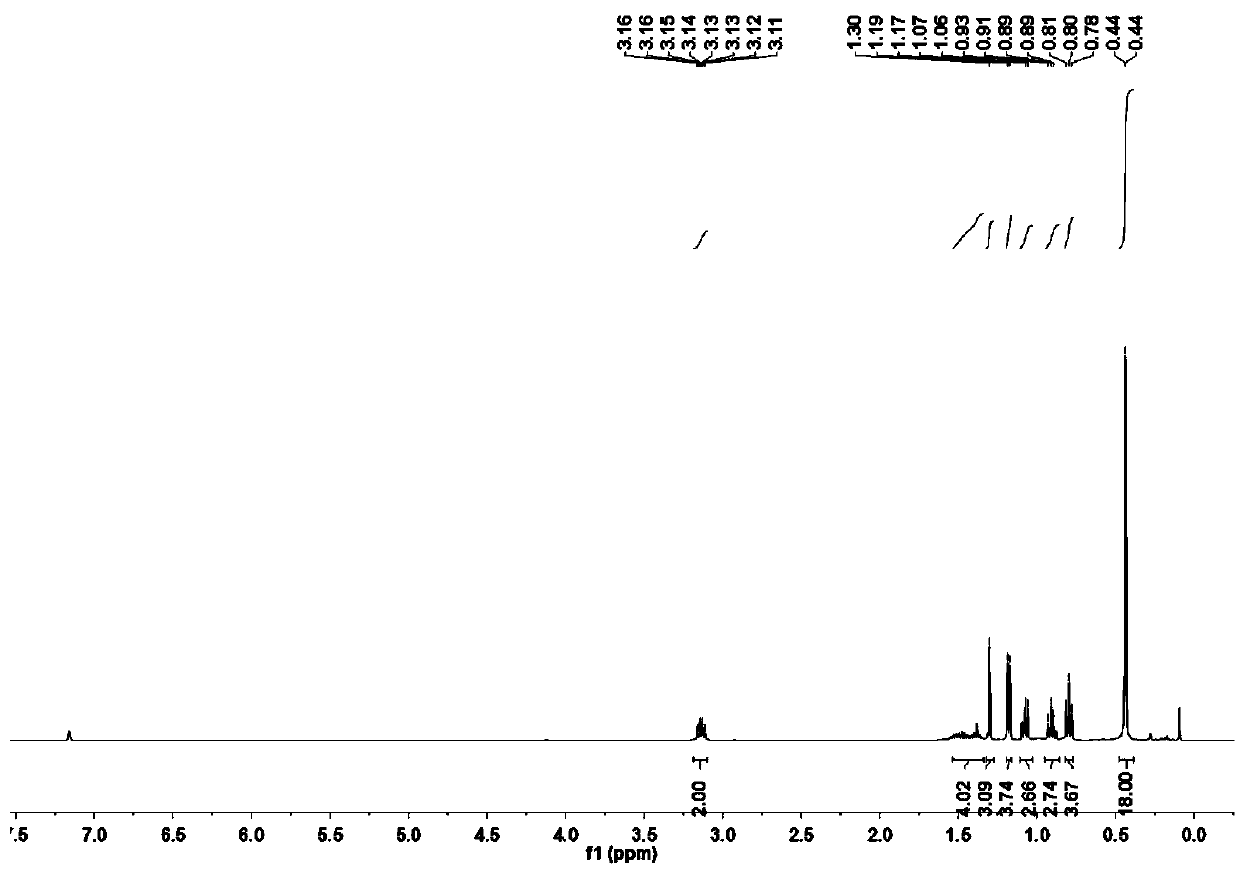

[0087] Embodiment 1: Preparation of (N, N'-di-sec-butyl-methylamidino) (hexamethyldisilazide) Ge (II)

[0088]

[0089] The preparation method of (N, N'-di-sec-butyl-methylamidino) (hexamethyldisilazide) Ge (II) shown in formula III is as follows:

[0090] The 100mL Schlenk bottle was evacuated and replaced with argon three times. Under the protection of argon, N,N'-di-sec-butyl-methylamidine ligand (0.510g, 3mmol) and diethyl ether (15mL) distilled to remove water were added, and the system was Colorless solution. At -78°C, n-butyllithium (1.2 mL, 3 mmol) was added dropwise. Slowly return to room temperature, and continue to stir for 3h, the system is a light yellow solution.

[0091] Another 100 mL Schlenk bottle was evacuated and replaced with argon three times, and germanium dichloride dioxane (0.693 g, 3 mmol) and diethyl ether (10 mL) distilled to remove water were added under the protection of argon. Under the protection of argon gas and at -78°C, the ether soluti...

Embodiment 2

[0096] Example 2: Preparation of GeTe alloy film based on atomic layer deposition

[0097] A kind of (N, N'-di-sec-butyl-methylamidino) (hexamethyldisilazide) Ge (II) as Ge source, see formula III, with N 2 h 4 As reducing agent, with (Et 3 Si) 2 Te is Te source and prepares GeTe alloy thin film atomic layer deposition method, including the following process:

[0098]

[0099] 1) With Si as the substrate, the deposition temperature is 150 °C, and the heating temperature of the Ge source (N,N'-di-sec-butyl-methylamidino) (hexamethyldisilazyl) Ge(II) is 50 ℃, make it vaporized, and use high-purity nitrogen as the carrier gas to pass through the gas phase Ge source (N,N'-di-sec-butyl-methylamidino) (hexamethyldisilazyl) Ge(II), The carrier gas flow rate was 20 sccm. The pulse time is 12s, and the waiting time is 10s;

[0100] 2) Use high-purity nitrogen to clean after completing a Ge source pulse, and the cleaning time is 25s;

[0101] 3) Reducing agent N 2 h 4 The he...

Embodiment 3

[0108] A kind of (N,N'-diisopropyl-n-butylamidino) (hexamethyldisilazide) Ge (II) is Ge source, see has formula IV, with N 2 h 4 As reducing agent, with (Et 3 Si) 2 Te is Te source and prepares GeTe alloy thin film atomic layer deposition method, including the following process:

[0109]

[0110] 1) with SiO 2As the substrate, the deposition temperature is 100°C, and the heating temperature of the Ge source (N,N'-diisopropyl-n-butylamidino)(hexamethyldisilazyl)Ge(II) is 70°C, so that For gasification, high-purity argon was used as the carrier gas, and the gas-phase Ge source (N,N'-diisopropyl-n-butylamidino) (hexamethyldisilazyl) Ge(II) was introduced into the gas phase. The air flow is 50 sccm. The pulse time is 5s, and the waiting time is 20s;

[0111] 2) After completing a Ge source pulse, use high-purity argon to clean, and the cleaning time is 45s;

[0112] 3) The reducing agent MeOH was heated at 70°C to vaporize it. High-purity argon was used as the carrier ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com