Core-shell structured sodium cobalt pyrophosphate/carbon positive electrode composite material, and preparation method and application thereof

A technology of cobalt sodium pyrophosphate and composite materials, which is applied in the direction of structural parts, battery electrodes, electrical components, etc., can solve the problems of difficult material preparation, difficult shape control, low voltage platform, etc., and achieve good repeatability, low cost, good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

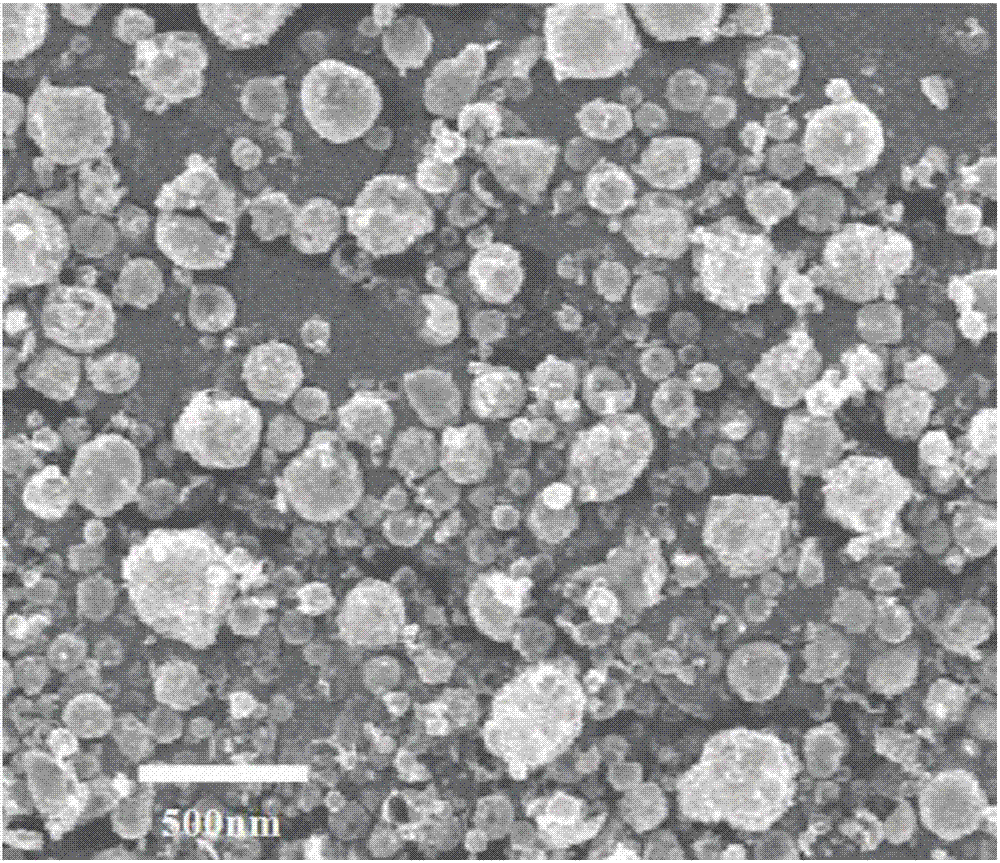

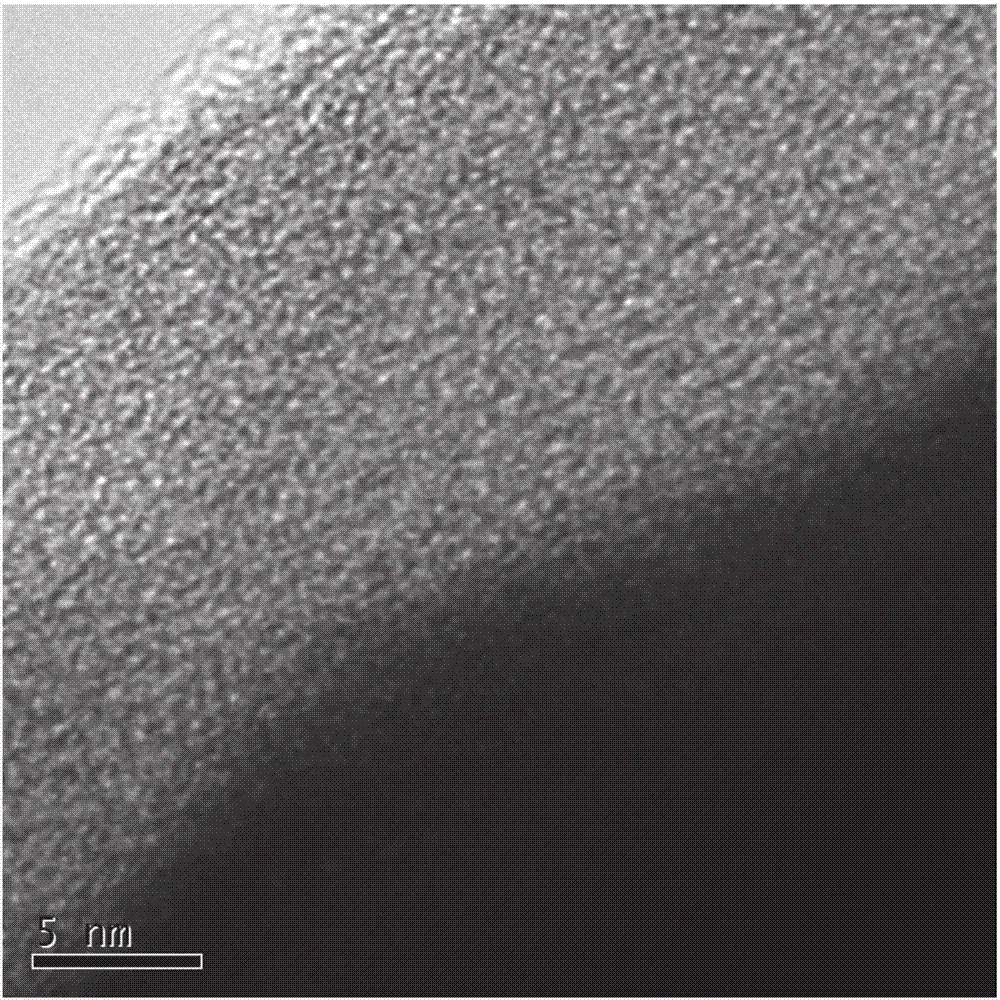

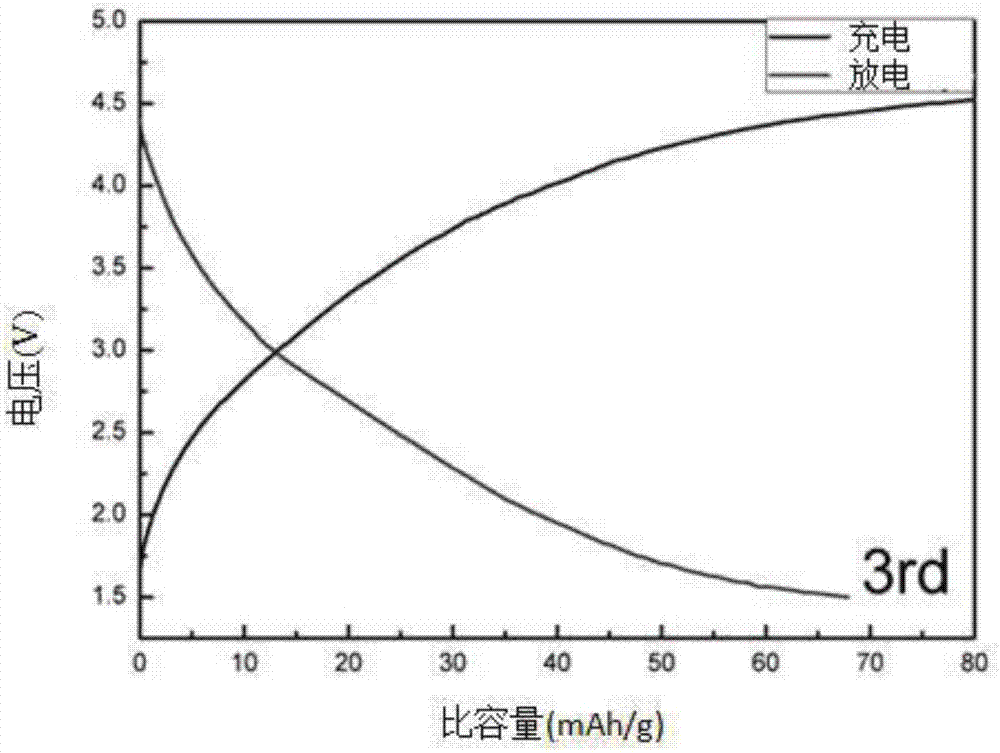

[0072] Weigh 0.01mol of cobalt nitrate, 0.01mol of sodium carbonate and 0.02mol of diammonium hydrogen phosphate and dissolve them in 50ml of deionized water, then add 0.3g of dopamine into the above solution, stir to form a uniform solution, and spray dry the aqueous solution. Set the temperature near the nozzle of the spray dryer to 180°C, the outlet temperature to 120°C, the flow rate of the mixed liquid to 400mL / h, and the inlet pressure to 0.6MPa to obtain the precursor. Finally, the above precursor was sintered at 650° C. for 3 h under an argon atmosphere, and the heating rate was 10° C. / min. Finally, the product is washed and dried. Obtain final product (positive electrode composite material); The sample specific surface area that obtains is 196m 2 / g. The SEM picture of the product that makes sees figure 1 ;Depend on figure 1 It is known that concentric spherical Na 2 CoP 2 o 7 / C material with a particle size of 180nm. The TEM images of the prepared samples ( ...

Embodiment 2

[0076] Weigh 0.01mol cobalt chloride, 0.01mol sodium oxalate and 0.02mol diammonium hydrogen phosphate and dissolve them in 15ml deionized water, then add 0.2g pyrrole to the above solution, stir to form a uniform solution, and spray dry the aqueous solution , set the temperature near the nozzle of the spray dryer to 160°C, the outlet temperature to 100°C, the flow rate of the mixed liquid to 400mL / h, and the inlet pressure to 0.5MPa to obtain the precursor. Finally, the above precursor was sintered at 650° C. for 6 h under an argon atmosphere, and the heating rate was 5° C. / min. Finally, the product is washed and dried. Obtain final product (positive electrode composite material); The sample specific surface area that obtains is 256m 2 / g. The sample particle size is 300nm. In the positive electrode composite material prepared in this embodiment, the thickness of the shell layer is about 50 nm.

[0077] The cathode composite material prepared in this embodiment was used a...

Embodiment 3

[0079] Weigh 0.01mol cobalt chloride, 0.02mol sodium acetate and 0.02mol diammonium hydrogen phosphate and dissolve them in 100ml deionized water, then add 0.15g ascorbic acid to the above solution, stir to form a uniform solution, and spray dry the aqueous solution , set the temperature near the nozzle of the spray dryer to 200°C, the outlet temperature to 80°C, the flow rate of the mixed liquid to 500mL / h, and the inlet pressure to 0.2MPa to obtain the precursor. Finally, the above precursor was sintered at 800° C. for 8 h under an argon atmosphere, and the heating rate was 5° C. / min. Finally, the product is washed and dried. Obtain final product (positive electrode composite material); The sample specific surface area that obtains is 135m 2 / g. The sample particle size is 900nm. In the positive electrode composite material prepared in this embodiment, the thickness of the shell layer is about 50 nm.

[0080] The cathode composite material prepared in this embodiment was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com