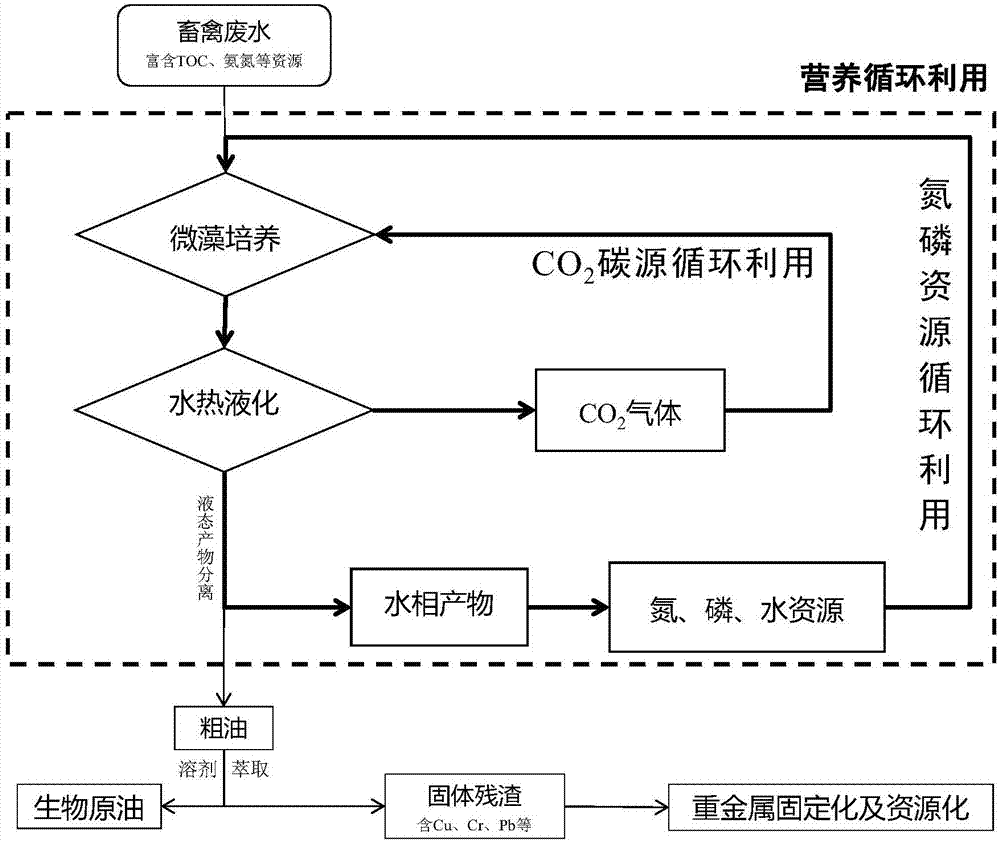

Method for livestock wastewater environment value-added utilization

A technology for wastewater and livestock and poultry, which is applied in the fields of animal husbandry wastewater treatment, chemical instruments and methods, and water pollutants to avoid environmental pollution and improve the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Chicken manure biogas slurry is clarified after flocculation and sedimentation, and then UF (ultrafiltration) membrane is used for ultrafiltration to remove suspended solids in wastewater, increase light transmittance, and then obtain filtered chicken manure biogas slurry.

[0050] The filtered chicken manure biogas slurry is diluted, wherein the filtered chicken manure biogas slurry accounts for 5-10% of the total volume of the diluted solution.

[0051] The diluted solution is placed in a microalgae culture pool, the domesticated chlorella is inoculated in the solution, and cultivated in the microalgae culture pool under light conditions.

[0052] (2) Cultivate in the microalgae culture pond to harvest chlorella when the biomass is 2g / L, adjust the pH of the water in the culture pond to 7.1 with HCl, and adjust the water content of the microalgae to 80 ± 0.2% after harvesting, which is mud shape.

[0053] (3) Take 50ml of microalgae mud and add it into a 100ml hy...

Embodiment 2

[0058] (1) The waste water from pig farm flushing manure is clarified by flocculation and sedimentation, and then the suspended matter in the waste water is removed by ultrafiltration to increase the light transmittance, and then the filtered pig farm water flushing waste water is obtained.

[0059] Diluting the filtered pig farm water for flushing manure, wherein the filtered pig farm water for flushing manure accounts for 5-6% of the total volume of the diluted solution.

[0060] The diluted solution is placed in a microalgae culture pool, the domesticated spirulina is inoculated in the solution, and cultivated in the microalgae culture pool under light conditions.

[0061] (2) Harvest the spirulina when the biomass is 3.5g / L in the microalgae culture tank, adjust the pH of the solution to 7.1 with NaOH, and adjust the water content of the microalgae to 85±0.2% after harvesting, which is muddy.

[0062] (3) Add 45ml of microalgae mud into a 100ml reaction kettle, and seal th...

Embodiment 3

[0067] (1) The vesicular manure wastewater from pig farms is clarified by flocculation and sedimentation, and then the suspended solids in the wastewater are removed by nanofiltration, and the light transmittance is increased, so as to obtain filtered vesicular manure wastewater from pig farms.

[0068] Dilute the filtered pig farm vesicle dung wastewater, wherein the filtered pig farm vesicle dung wastewater accounts for 6-7% of the total volume of the diluted solution.

[0069] The diluted solution is placed in a microalgae culture pool, the domesticated Dunaliella salina is inoculated in the solution, and cultured in the microalgae culture pool under light conditions.

[0070] (2) Harvest Dunaliella salina when the biomass is 1.2g / L in the microalgae culture tank, adjust the pH of the solution in the culture tank to 7.1 with HCl, and adjust the water content of the microalgae to 90±0.2% after harvesting, which is mud shape.

[0071] (3) Take 60ml of microalgae mud and add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com