High-temperature-resistant oxidation-resistance ceramic glaze and preparation method thereof

A ceramic glaze and anti-oxidation technology, which is applied in the field of ceramic glaze production, can solve the problems of large dirt on the surface of the porcelain, pinholes on the surface of the porcelain, darkening of the surface of the porcelain, etc., to achieve good machinability and expand melting Temperature, the effect of improving the elasticity of the glaze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

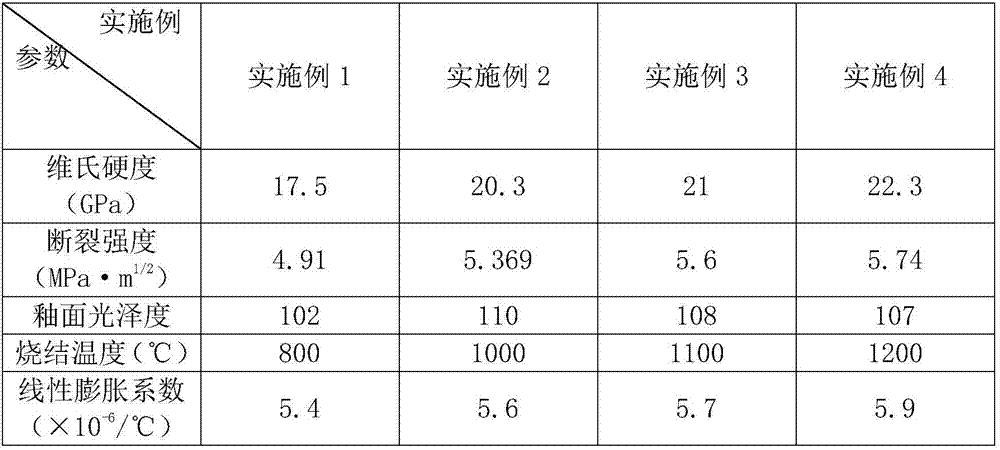

Embodiment 1

[0020] This embodiment provides a high-temperature-resistant and anti-oxidation daily-use ceramic glaze, including the following raw materials in parts by mass: 4 parts of nano-alumina; 35 parts of nano-silicon dioxide; 5 parts of nano-boron nitride powder, and 5 parts of nano-boron carbide powder ; 3 parts of zinc oxide; 5 parts of kaolin; 3 parts of calcined talc; 3 parts of sodium oxide; 3 parts of calcium oxide; 1 part of surfactant; 15 parts of glass wool industrial waste; share.

[0021] This embodiment also provides a method for preparing the above-mentioned high-temperature-resistant and anti-oxidation daily-use ceramic glaze, which includes the following steps:

[0022] (1) Preparation of antibacterial agent: glacial acetic acid, distilled water and dehydrated alcohol are uniformly mixed to obtain a solvent, then zinc nitrate, yttrium nitrate and surfactant are added in the described solvent according to the proportion, wherein glacial acetic acid, distilled water, T...

Embodiment 2

[0027] This embodiment provides a high-temperature-resistant and anti-oxidation daily-use ceramic glaze, including the following raw materials in parts by mass: 5 parts of nano-alumina; 43 parts of nano-silicon dioxide; 7 parts of nano-boron nitride powder and 7 parts of nano-boron carbide powder ; 4 parts of zinc oxide; 8 parts of kaolin; 4 parts of calcined talc; 4 parts of sodium oxide; 4 parts of calcium oxide; 2 parts of surfactant; 16 parts of glass fiber industrial waste; share.

[0028] This embodiment also provides a method for preparing the above-mentioned high-temperature-resistant and anti-oxidation daily-use ceramic glaze, which includes the following steps:

[0029] (1) Preparation of antibacterial agent: glacial acetic acid, distilled water and dehydrated alcohol are uniformly mixed to obtain a solvent, then zinc nitrate, yttrium nitrate and surfactant are added in the described solvent according to the proportion, wherein glacial acetic acid, distilled water, ...

Embodiment 3

[0034] This embodiment provides a high-temperature-resistant and anti-oxidation daily-use ceramic glaze, including the following raw materials in parts by mass: 6 parts of nano-alumina; 46 parts of nano-silicon dioxide; 8 parts of nano-boron nitride powder, and 8 parts of nano-boron carbide powder ; 5 parts of zinc oxide; 9 parts of kaolin; 4.5 parts of calcined talc; 5 parts of sodium oxide; 5 parts of calcium oxide; 2.5 parts of surfactant; 17 parts of glass wool industrial waste; share.

[0035]This embodiment also provides a method for preparing the above-mentioned high-temperature-resistant and anti-oxidation daily-use ceramic glaze, which includes the following steps:

[0036] (1) Preparation of antibacterial agent: glacial acetic acid, distilled water and dehydrated alcohol are uniformly mixed to obtain a solvent, then zinc nitrate, yttrium nitrate and surfactant are added in the described solvent according to the proportion, wherein glacial acetic acid, distilled water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com