High-temperature anti-oxidization niobium alloy surface composite silicide coating and preparing method

A high-temperature anti-oxidation and surface composite technology, which is applied in metal material coating process, coating, superimposed layer plating and other directions to achieve the effect of excellent service effect, short preparation period and excellent high-temperature anti-oxidation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

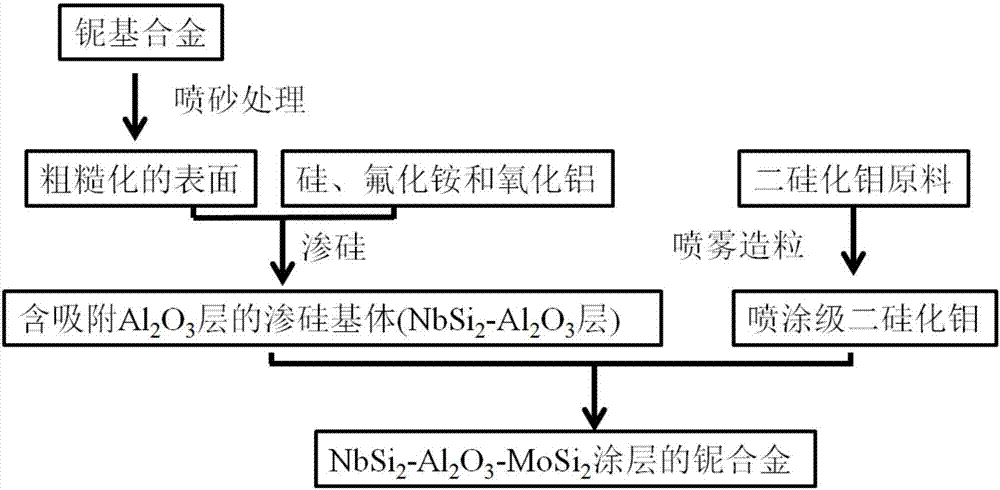

Method used

Image

Examples

Embodiment example 1

[0044] Step 1: Pretreatment of the alloy matrix to prepare alloy surfaces with different roughness: cutting the refractory niobium alloy into 10×10×3mm by wire 3 After grinding the rounded corners with a high-speed grinding wheel, pickle with 40wt.% nitric acid for 10 minutes, and dry at 80°C; roughen the pickled niobium alloy with 30-mesh corundum sand with a pressure of 0.5MPa, and sandblast The angle is 45°, and the sandblasting distance is 10cm; after sandblasting, ultrasonically clean with absolute ethanol for 30min, and the ultrasonic power is 80W. For comparison, a part of the samples after pickling were mechanically ground and polished with No. 300, No. 500 and No. 800 water-grinding paper respectively, and the polished samples were cleaned with 80W ultrasonic; Samples were dried in an oven at 80°C for later use;

[0045] Step 2: Prepare Al-containing 2 o 3 NbSi adsorbed particles 2 Inner coating: Weigh 10% Si powder, 10% NH respectively according to mass fraction ...

Embodiment example 2

[0049] Step 1: Obtain a roughened alloy surface: Wire cut the refractory niobium alloy into 10×10×3mm 3 After grinding the rounded corners with a high-speed grinding wheel, pickle with 50wt.% nitric acid for 10 minutes, and dry at 80°C; roughen the pickled niobium alloy with 30-mesh corundum sand with a pressure of 0.6MPa, and sandblast The angle is 90°, and the sandblasting distance is 5cm; after sandblasting, ultrasonically clean with anhydrous ethanol for 30 minutes, and the ultrasonic power is 80W; the cleaned samples are dried in an oven at 80°C for later use;

[0050] Step 2: Prepare Al-containing 2 o 3 NbSi adsorbed particles 2 Inner coating: Weigh 5% Si powder, 5% NH respectively according to mass fraction 4 F and 90% Al 2 o 3 Add the powder into the ball mill tank and mill it for 1 hour to make the infiltrating powder, the ball milling speed is 70r / min; use the embedding method in Case 1 to put the roughened sample into the graphite crucible, and cover the crucib...

Embodiment example 3

[0054] Step 1: Obtain a roughened alloy surface: Wire cut the refractory niobium alloy into 10×10×3mm 3 After grinding the rounded corners with a high-speed grinding wheel, pickle with 45wt.% nitric acid for 10 minutes, and dry at 80°C; roughen the pickled niobium alloy with 30-mesh corundum sand with a pressure of 0.8MPa, and sandblast The angle is 90°, and the sandblasting distance is 5cm; after sandblasting, ultrasonically clean with anhydrous ethanol for 30 minutes, and the ultrasonic power is 80W; the cleaned samples are dried in an oven at 80°C for later use;

[0055] Step 2: Prepare Al-containing 2 o 3 NbSi adsorbed particles 2 Inner coating: Weigh 15% Si powder, 15% NH respectively according to mass fraction 4 F and 70% Al 2 o 3 Add the powder into the ball mill tank and mill it for 1 hour to make the infiltrating powder, the ball milling speed is 70r / min; use the embedding method in Case 1 to put the roughened sample into the graphite crucible, and cover the cruc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com