Preparation method for ITO (indium tin oxide) evaporation target

A technology of tin oxide and powder, applied in the field of evaporative coating material preparation, can solve the problems of inability to achieve cracking and insufficient bonding strength, achieve good thermal shock resistance and reduce sintering temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

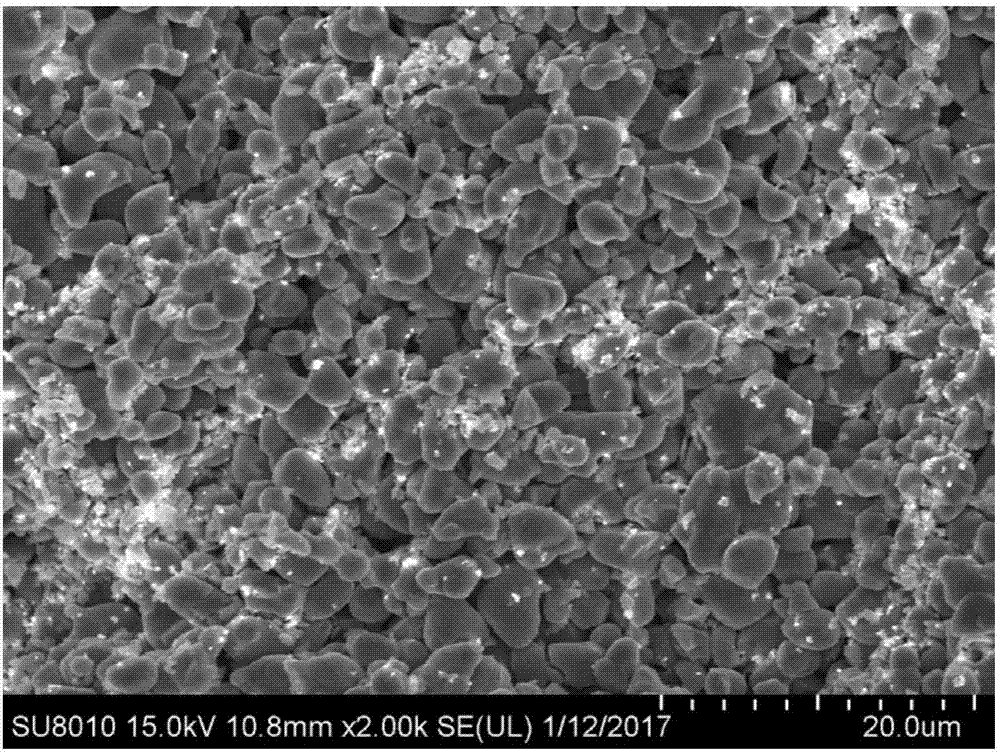

Image

Examples

Embodiment 1

[0025] This embodiment provides a method for preparing an ITO evaporation target, comprising the following steps:

[0026] 1) Carry out heat treatment on the raw material indium oxide micron powder and tin oxide nano powder, the heat treatment temperature is 800-900°C, and the heat treatment time is 5 hours; the particle size of the tin oxide powder is 10-20nm;

[0027] 2) Mix the heat-treated raw material indium oxide micro-powder and tin oxide nano-powder in a mass ratio of 9:1, and perform ball milling and mixing in an ethanol medium. The ball milling time is 12 hours, then add additives, and continue mixing for 14 hours. The powder is uniformly coated with organic matter, and the additives include binder, lubricant and dispersant; the binder is polyvinyl alcohol, propylene polymer or acrylic emulsion; the lubricant is monoglyceride; the dispersant is a weight ratio of 1 : 1.5 mixture of citric acid and polyethylene glycol;

[0028] 3) The fat-blended ITO powder treated in...

Embodiment 2

[0035] This embodiment provides a method for preparing an ITO evaporation target, comprising the following steps:

[0036] 1) Carry out heat treatment on the raw material indium oxide micron powder and tin oxide nano powder, the heat treatment temperature is 800°C, and the heat treatment time is 8 hours; the particle size of the tin oxide powder is 10-20nm;

[0037] 2) Mix the heat-treated raw material indium oxide micro-powder and tin oxide nano-powder in a mass ratio of 9:1, and perform ball milling and mixing in an ethanol medium. The ball milling time is 8 hours, then add additives, and continue mixing for 24 hours. The powder is uniformly coated with organic matter, and the additives include binder, lubricant and dispersant; the binder is polyvinyl alcohol, propylene polymer or acrylic emulsion; the lubricant is monoglyceride; the dispersant is a weight ratio of 1 : 1 mixture of citric acid and polyethylene glycol;

[0038] 3) The fat-blended ITO powder treated in step 2...

Embodiment 3

[0045] This embodiment provides a method for preparing an ITO evaporation target, comprising the following steps:

[0046] 1) Carry out heat treatment on the raw material indium oxide micron powder and tin oxide nano powder, the heat treatment temperature is 1000°C, and the heat treatment time is 2 hours; the particle size of the tin oxide powder is 10-20nm;

[0047] 2) Mix the heat-treated raw material indium oxide micro-powder and tin oxide nano-powder at a mass ratio of 9:1, and perform ball milling and mixing in an ethanol medium. The ball milling time is 16 hours, then add additives, and continue mixing for 4 hours to make The powder is uniformly coated with organic matter, and the additives include binder, lubricant and dispersant; the binder is polyvinyl alcohol, propylene polymer or acrylic emulsion; the lubricant is monoglyceride; the dispersant is a weight ratio of 1 : 2 mixtures of citric acid and polyethylene glycol;

[0048] 3) The fat-blended ITO powder treated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com