A kind of preparation method of mussel oligosaccharide and its product and application

A technology of mussel polysaccharides and mussels, which is applied in the field of preparation of mussel oligosaccharides, can solve the problems of no reports of mussel oligosaccharides, and achieve the effects of mild conditions, simple process and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 mussel polysaccharide preparation

[0038] (1) Raw material processing: take the dried frozen and boiled mussels with thick shells produced in Baolei County, Zhejiang Province as raw materials, pulverize them with a pulverizer, and pass through a 20-mesh sieve to obtain dried mussel powder;

[0039] (2) Polysaccharide extraction: put the dried mussel powder prepared in step (1) into the extraction tank, add 6 times the volume of water, extract at 100°C for 2 hours, and the rotation speed of the stirring paddle is 60rpm:

[0040] (3) Slag removal: Use a 50-mesh screen to separate mussel meat residue and polysaccharide extract:

[0041] (4) Enzymolysis: adjust the pH of the polysaccharide extract prepared in step (3) to 8.0 with NaOH, add alkaline protease with a mass ratio of 0.2%, and enzymolyze at 50°C for 2 hours, and after the enzymolysis is completed, place it at 80°C Inactivate for 15 minutes to obtain the enzymatic hydrolysis solution;

[0042] (5) ...

Embodiment 2

[0046] Embodiment 2 Yeast cell preparation

[0047] (1) Incline cultivation

[0048] Inoculate Saccharomyces cerevisiae (CICC No. 1002) on the slant of YPD medium (mass percentage: 2% peptone, 1% yeast powder, 2% glucose, 2% agar, natural pH), culture at 28°C for 48h, and rinse with sterile water Inclined surface to obtain a bacterial suspension, that is, a seed solution.

[0049] (2) shake flask culture

[0050] Put the seed solution into YPD medium (mass percentage: 2% peptone, 1% yeast powder, 2% glucose, natural pH), inoculum size is 5%, cultivate at 28°C for 30h, centrifuge at 10000rpm for 3min, discard the supernatant, and obtain Saccharomyces cerevisiae cells.

Embodiment 3

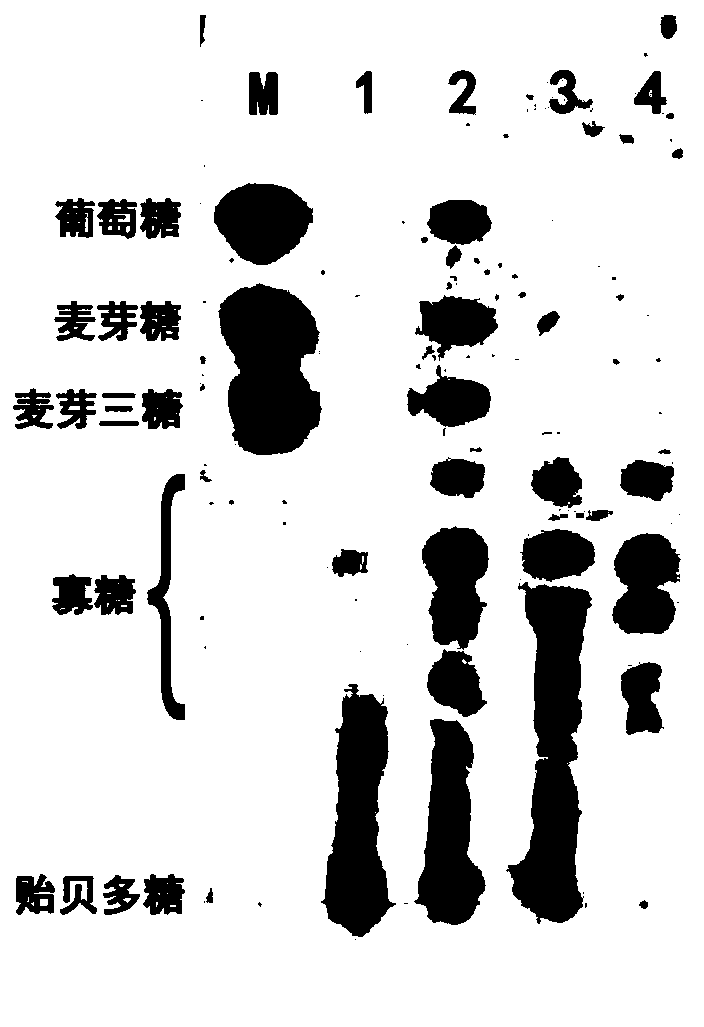

[0051] Embodiment 3 mussel oligosaccharide preparation

[0052](1) The mussel polysaccharide powder of Example 1 was dissolved in distilled water to prepare a 10% polysaccharide solution, and the pH was adjusted to 5.5 with HCl to obtain the mussel polysaccharide solution;

[0053] (2) adding medium-temperature α-amylase to the mussel polysaccharide solution described in step (1) to make the concentration 0.5 g / L, incubating at 50°C for 0.5h, and inactivating at 100°C for 15min to obtain a mussel polysaccharide hydrolyzate;

[0054] (3) The mussel polysaccharide hydrolyzate described in step (2) is filtered with a 0.22 μm filter membrane, and the filtrate is collected to obtain the mussel oligosaccharide solution I;

[0055] (4) Add the yeast cells of Example 1 to the mussel oligosaccharide solution I described in step (3) according to the mass volume ratio of 8%, culture on a shaking table at 30° C. and 150 rpm for 30 h, and centrifuge to get the supernatant to obtain mussels...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com