A degreaser for oily sewage treatment in oil fields and preparation method thereof

A technology for degreasing agent and oily sewage, which is applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. It can solve problems such as high price, unsatisfactory effect of oily sewage, complicated preparation methods, etc. , to achieve the effects of not easy to decompose, meet environmental protection, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: Degreaser M 1 and its preparation method

[0029] (1) Degreaser M 1 The composition, components and molecular formula are as follows:

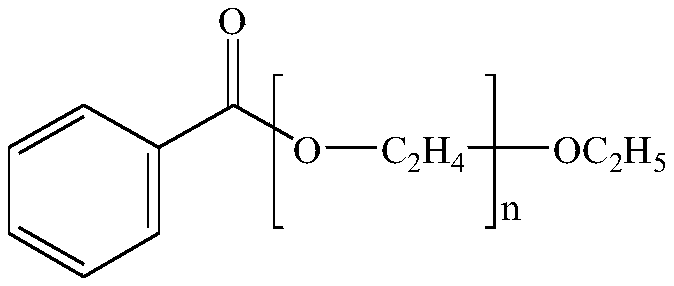

[0030] Degreaser M 1 It is a non-ionic degreasing agent produced by the reaction of ethyl benzoate and ethylene oxide at a molar ratio of 1:2, and its molecular formula is as follows:

[0031]

[0032] (2) Degreaser M 1 The preparation method is as follows:

[0033] ① Weigh 1 mol of ethyl benzoate and 75.1 g of catalyst, place them in an autoclave, purge the pipeline and the reactor with nitrogen for 5 minutes, then stir and heat up to 80 °C at a stirring rate of 200 rpm for 5 minutes, then feed 2mol of ethylene oxide, and then feed nitrogen to make the pressure of the reactor reach 0.2MPa, adjust the stirring rate to 470rpm, and raise the temperature to 100°C. After 3 hours of reaction, the system is cooled to room temperature with circulating cooling water, and the obtained mixture.

[0034] ②The above mixture ...

Embodiment 2

[0037] Embodiment 2: Degreaser M 2 and its preparation method

[0038] (1) Degreaser M 2 The composition, components and molecular formula are as follows:

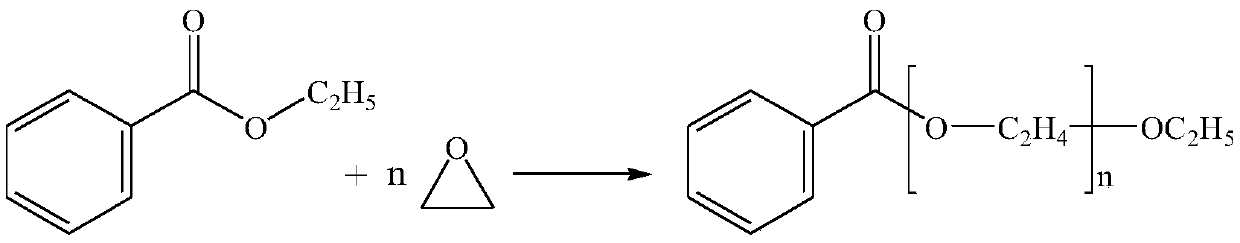

[0039] Degreaser M 2 It is a non-ionic degreasing agent produced by the reaction of ethyl benzoate and ethylene oxide at a molar ratio of 1:3, and its molecular formula is as follows:

[0040]

[0041] (2) Degreaser M 2 The preparation method is as follows:

[0042] ① Weigh 1 mol of ethyl benzoate and 120.1 g of catalyst, place them in an autoclave, purge the pipeline and the reactor with nitrogen for 6 minutes, then stir and heat up to 90°C at a stirring rate of 230 rpm for 10 minutes, then feed 3mol of ethylene oxide, and then feed nitrogen to make the pressure of the reactor reach 0.5MPa, adjust the stirring rate to 450rpm, and raise the temperature to 120°C. After 4 hours of reaction, the system is cooled to room temperature with circulating cooling water, and the obtained mixture.

[0043] ②The above mixture...

Embodiment 3

[0046] Embodiment 3: Degreaser M 3 and its preparation method

[0047] (1) Degreaser M 3 The composition, components and molecular formula are as follows:

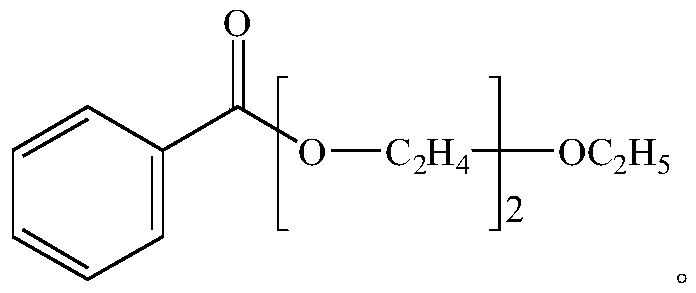

[0048] Degreaser M 3 It is a non-ionic degreasing agent produced by the reaction of ethyl benzoate and ethylene oxide at a molar ratio of 1:4, and its molecular formula is as follows:

[0049]

[0050] (2) Degreaser M 3 The preparation method is as follows:

[0051]① Weigh 1mol of ethyl benzoate and 180.2g of catalyst, place them in an autoclave, purge the pipeline and reactor with nitrogen for 8min, then stir and heat up to 85°C, the stirring rate is 260rpm, after 12min, feed 4mol of ethylene oxide, and then feed nitrogen to make the pressure of the reactor reach 0.6MPa, adjust the stirring rate to 400rpm, and raise the temperature to 150°C. After 4h of reaction, the system is cooled to room temperature with circulating cooling water to obtain mixture.

[0052] ②The above mixture is subjected to gas-liquid separ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com