Solid-state battery and preparation method therefor

A solid-state battery, solid electrolyte technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, final product manufacturing, etc., can solve the problems of thin thickness, high production cost, low battery energy density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

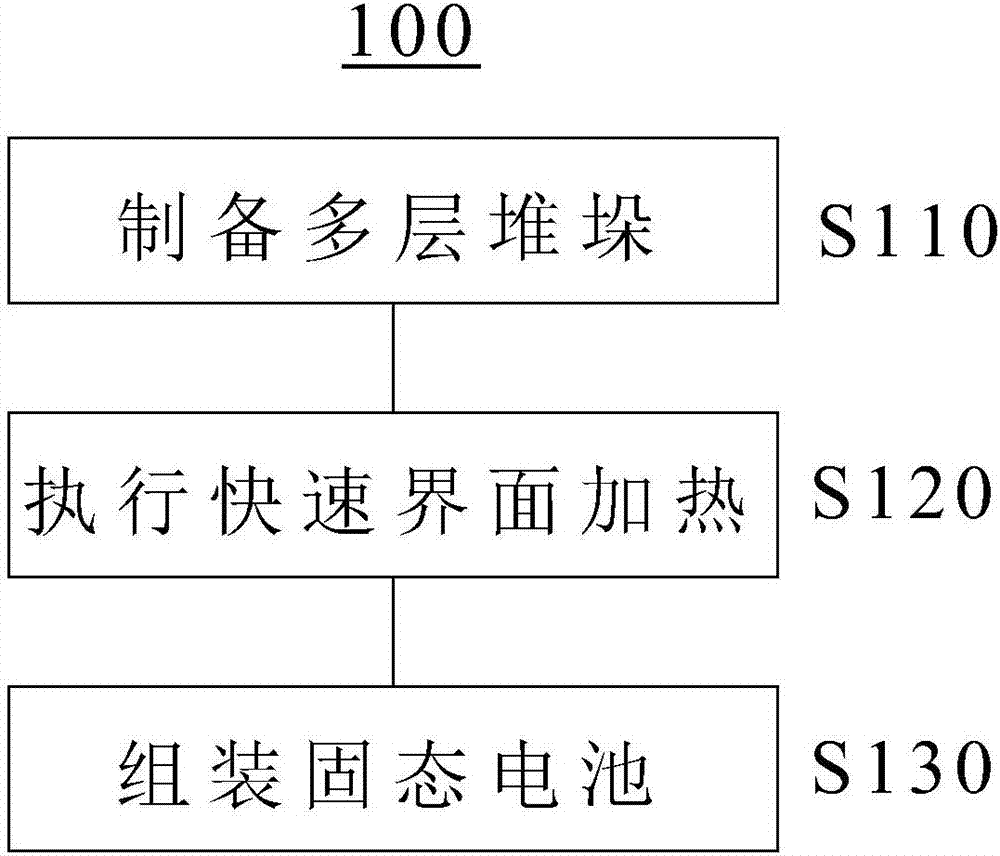

Method used

Image

Examples

example 1

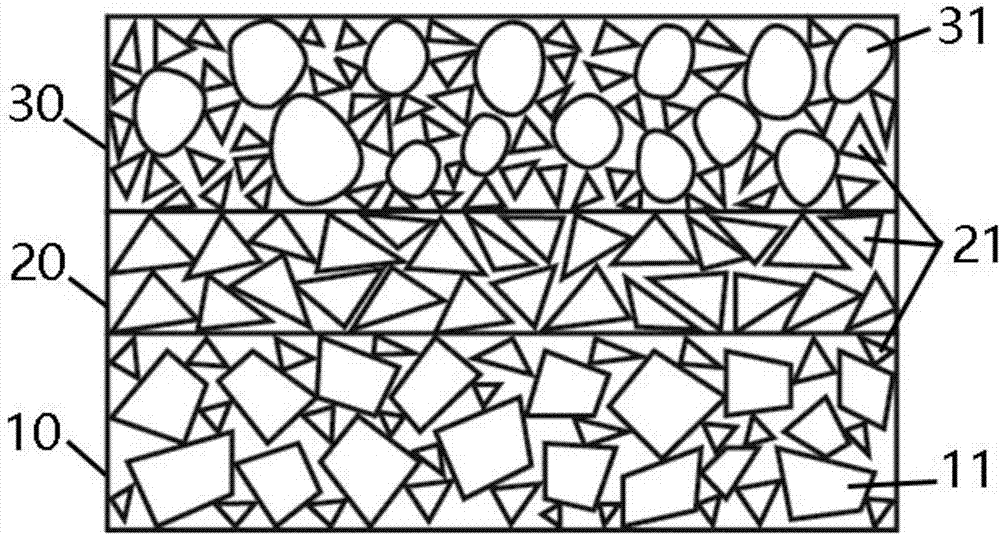

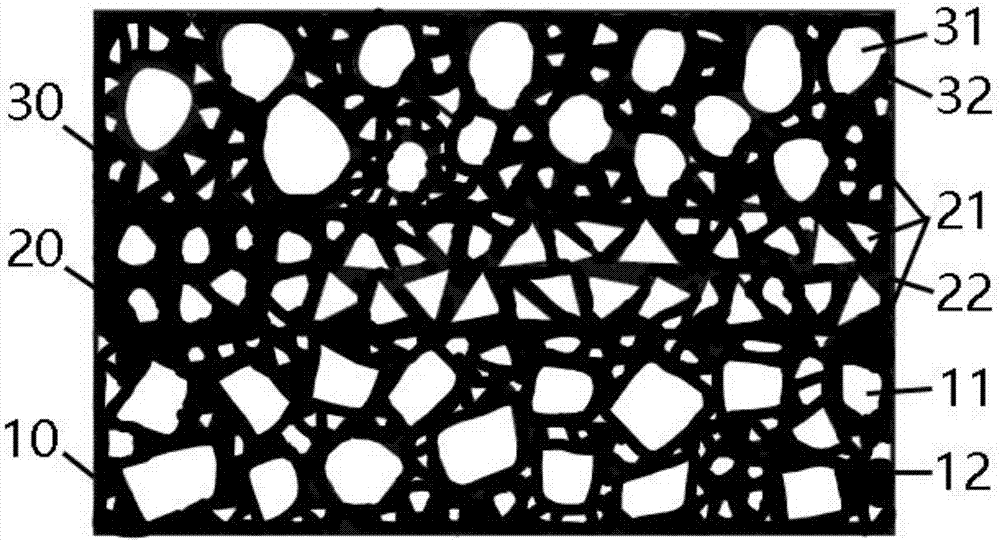

[0088] By separately preparing: the positive electrode layer mixed material, in which the mass ratio of active material lithium cobaltate, electrolyte LAGP, conductive carbon and binder PVDF is 7:3:0.5:0.5, and NMP is used as a solvent to prepare a slurry; the electrolyte layer is mixed The material, in which the mass ratio of electrolyte LAGP and binder PVDF is 90:10, and NMP is used as a solvent to prepare slurry. The positive electrode slurry was coated on the carrier Al with a thickness of 10 μm and a coating thickness of 100 μm. Then the electrolyte slurry was coated on the carrier Cu, and the spray thickness was 150 μm. The positive electrode layer and the electrolyte layer are overlapped to form a stacking layer, and the obtained stacking layer is subjected to mechanical wave heating treatment for a heating time of 6 s and a pressure of 1 MPa to obtain a positive electrode-electrolyte sheet. The microstructure of the positive electrode-electrolyte sheet is as Image 6 T...

example 2

[0090] The positive electrode layer mixed material, the electrolyte layer mixed material and the negative electrode layer mixed material are mixed separately by a vibration mixing method. The mixed material of the positive electrode layer includes lithium iron phosphate, the electrolyte LATP, the binder PVA, and the conductive additive super P; the mixed material of the electrolyte layer includes the electrolyte LATP and the binder PVA; the mixed material of the negative electrode layer includes the negative active material graphite, adhesive Binding agent CMC. Three uniformly mixed materials were sprayed on the current collector Al in a large area, and Cu was added as the negative current collector. The stacked structure obtained by spraying is heated by ultrasonic for 0.1s and 1 MPa to obtain the battery cell. The microstructure of the battery cell is like Figure 8 The SEM photo is shown. Due to the short processing time, the particles are not completely melted, only a sma...

example 3-12

[0092] Table 7 below lists the material composition and rapid interface heating method of Examples 3-12, as well as the voltage range and first week efficiency of the resulting battery.

[0093] Table 7 Examples 3-12

[0094]

[0095] By comparing the results of Comparative Example 1 above with the results of Examples 1-12 according to the present invention, it can be found that, compared to the solid-state battery prepared by the long-term sintering method alone, the present invention uses the rapid interface heating method to control the particle interface. Including electrolyte particles, electrolyte and positive electrode particles, the interface between negative electrode and electrolyte particles is heated at a high temperature for a short time, which can improve the interface contact, while inhibiting the inter-diffusion of the interface and the formation of the inert layer, so as to improve the interface performance, thereby improving The cycle performance of solid-state ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com