Composite premixed feed lick brick for grazing yak

A technology of premixed feed and licking bricks, which is applied in animal feed, animal feed, applications, etc., can solve the problems of yaks lack of forage, low yak breeding efficiency, and long time for slaughter, so as to achieve good supplementary feeding effect and increase feed intake And digestion efficiency, enhance the effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

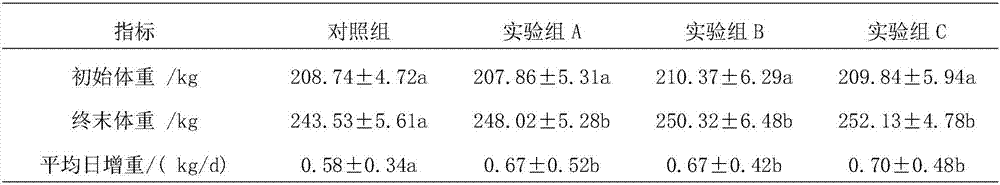

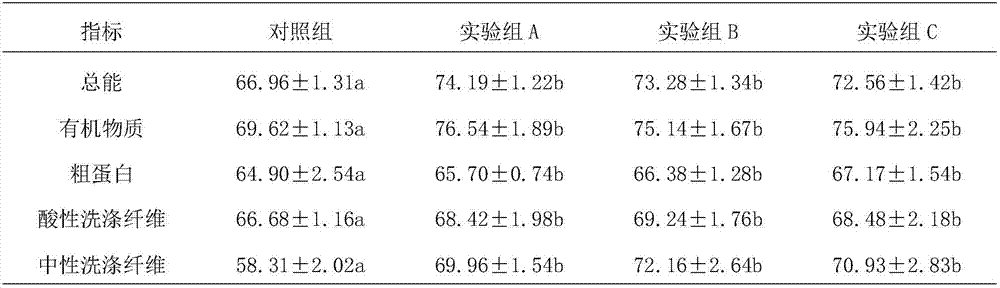

Examples

Embodiment 1

[0023] Produce licking brick A according to the following method:

[0024]Proportioning raw materials according to the following formula: 57.1% of salt, 6% of cement, 8% of bentonite, 4% of urea, 4% of ammonium chloride, 2% of calcium formate containing 30% of calcium by mass, 0.05% of flavoring agent, and phosphorus by mass 24.58% calcium hydrogen phosphate 14%, 0.3% ferrous sulfate containing iron mass ratio 30%, 0.2% copper sulfate containing copper mass ratio 25%, 0.6% zinc sulfate containing zinc mass ratio 34.5%, magnesium mass ratio 15% magnesium sulfate 0.75%, manganese-containing mass ratio 31.8% manganese sulfate 0.8%, selenium-containing mass ratio 0.2% sodium selenite 0.05%, cobalt-containing mass ratio 1.24% cobalt chloride 0.05%, iodine-containing mass ratio Calcium iodate 0.1%, rumenin 1%, compound multidimensional 1%; said compound multidimensional is composed of the following components by mass percentage: 5*10 6 Vitamin A in IU / kg: 1%, 5*10 5 Vitamin D3 in ...

Embodiment 2

[0030] Produce licking brick B according to the following method:

[0031] Proportioning raw materials according to the following formula: 54.08% of salt, 4% of cement, 9.06% of bentonite, 4.5% of urea, 5% of ammonium chloride, 2.5% of calcium formate containing calcium mass ratio of 30%, flavoring agent 0.06%, and phosphorus mass ratio 24.58% calcium hydrogen phosphate 15%, 0.4% ferrous sulfate containing iron mass ratio 30%, 0.25% copper sulfate containing 25% copper mass ratio, 0.8% zinc sulfate containing 34.5% zinc mass ratio, magnesium mass ratio 15% magnesium sulfate 0.8%, manganese-containing mass ratio 31.8% manganese sulfate 0.9%, selenium-containing mass ratio 0.2% sodium selenite 0.06%, cobalt-containing mass ratio 1.24% cobalt chloride 0.06%, iodine-containing mass ratio Compared with 1.24%, calcium iodate 0.13%, rumenin 1.1%, compound multidimensional 1.3%; the compound multidimensional is composed of the following components by mass percentage: 5*10 6 Vitamin A...

Embodiment 3

[0037] Produce licking brick C according to the following method:

[0038] Proportioning raw materials according to the following formula: 61% of salt, 7.72% of cement, 7.02% of bentonite, 3.5% of urea, 3.5% of ammonium chloride, 1.5% of calcium formate containing 30% of calcium by mass, 0.05% of flavoring agent, and phosphorus by mass 24.58% calcium hydrogen phosphate 12%, 0.2% ferrous sulfate containing iron mass ratio 30%, 0.15% copper sulfate containing 25% copper mass ratio, 0.4% zinc sulfate containing 34.5% zinc mass ratio, magnesium mass ratio 15% magnesium sulfate 0.6%, manganese-containing mass ratio 31.8% manganese sulfate 0.6%, selenium-containing mass ratio 0.2% sodium selenite 0.04%, cobalt-containing mass ratio 1.24% cobalt chloride 0.04%, iodine-containing mass ratio Compared with 1.24%, calcium iodate 0.08%, rumenin 0.8%, compound multidimensional 0.8%; the compound multidimensional is composed of the following components by mass percentage: 5*10 6 Vitamin A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com