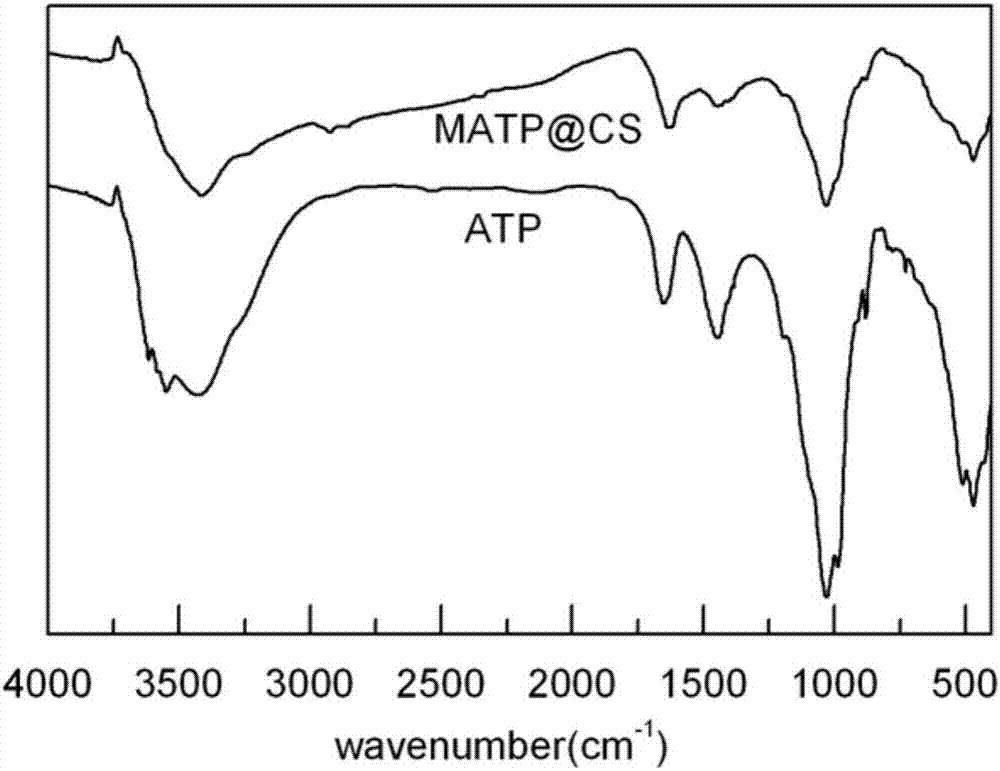

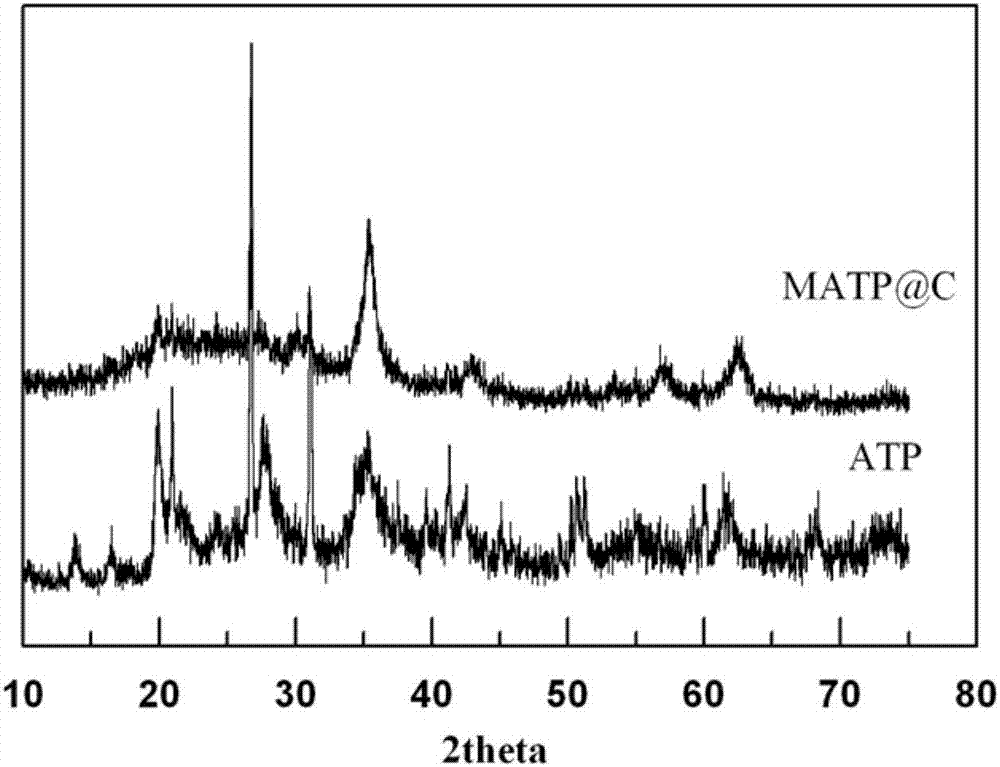

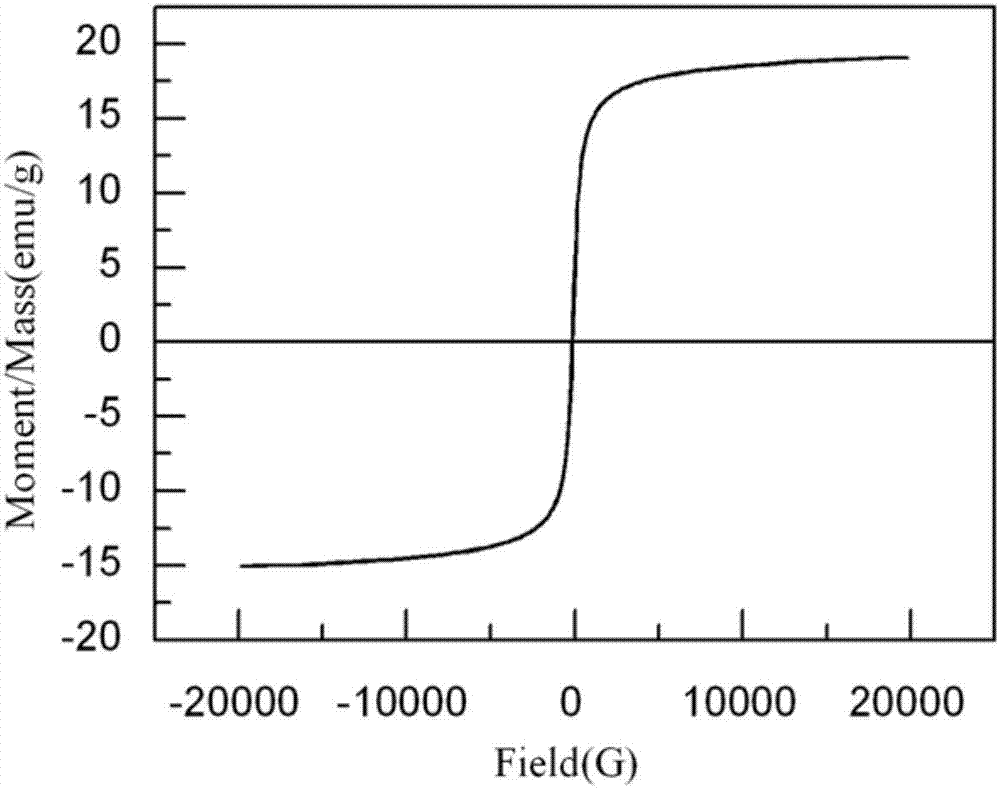

Preparation and application of attapulgite/Fe3O4/carbon composite material

A carbon composite material, attapulgite technology, applied in water/sludge/sewage treatment, alkali metal compounds, water/sewage treatment and other directions, can solve the problems of few preparation steps, inability to generate, difficult to control reaction, etc., to achieve the purpose Wide, easy-to-control, strong adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) Add 1.0 g of ferric chloride hexahydrate and 0.5 g of attapulgite to 70 mL of ethylene glycol, add 0.3 g of chitosan powder after vigorous stirring, and ultrasonically disperse for 30 minutes to obtain a light yellow viscous liquid;

[0041] 2) Add 3.0 g of anhydrous sodium acetate powder to the viscous liquid obtained in step 1), and stir continuously for 30 minutes;

[0042] 3) Transfer the suspension solution obtained in step 2) to a 100mL polytetrafluoroethylene reactor (filling degree ≤80%), and react under hydrothermal conditions at 180°C for 24h;

[0043] 4) Magnetic separation after natural cooling, washing with absolute ethanol and distilled water for 3 to 4 times, the resulting black product is dried in an electric blast drying oven at 60°C, ground and sieved to obtain attapulgite / Fe 3 O 4 / C Nanocomposite materials;

[0044] 5) Weigh out 0.05g of the magnetic nanocomposite material prepared in Example 1, and add it to 40mLK 2 Cr 2 O 7 In the solution (pH=2,300mg / L)...

Embodiment 2

[0046] 1) Same as Example 1, except that the chitosan added during the preparation of the magnetic nanocomposite is 1.5g;

[0047] 2) Weigh 0.05g of the adsorbent prepared in step 1) and add it to 40mLK 2 Cr 2 O 7 In the solution (pH=2,300mg / L), oscillate to adsorption equilibrium at 298K. After magnetic separation, the Cr(VI) concentration in the supernatant is measured, and the Cr(VI) removal rate is calculated to be 82.9%.

Embodiment 3

[0049] 1) Same as Example 1, except that the amount of chitosan added during the preparation of the magnetic nanocomposite is 3.0g;

[0050] 2) Weigh out 0.05g of the adsorbent prepared in step 1) and add to 40mLK 2 Cr 2 O 7 In the solution (pH=2,300mg / L), oscillate to adsorption equilibrium at 298K. After magnetic separation, the concentration of Cr(VI) in the supernatant is measured, and the Cr(VI) removal rate is calculated to be 93.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com