A preparation method and application of fluorescent sulfur-doped nitrogen dots

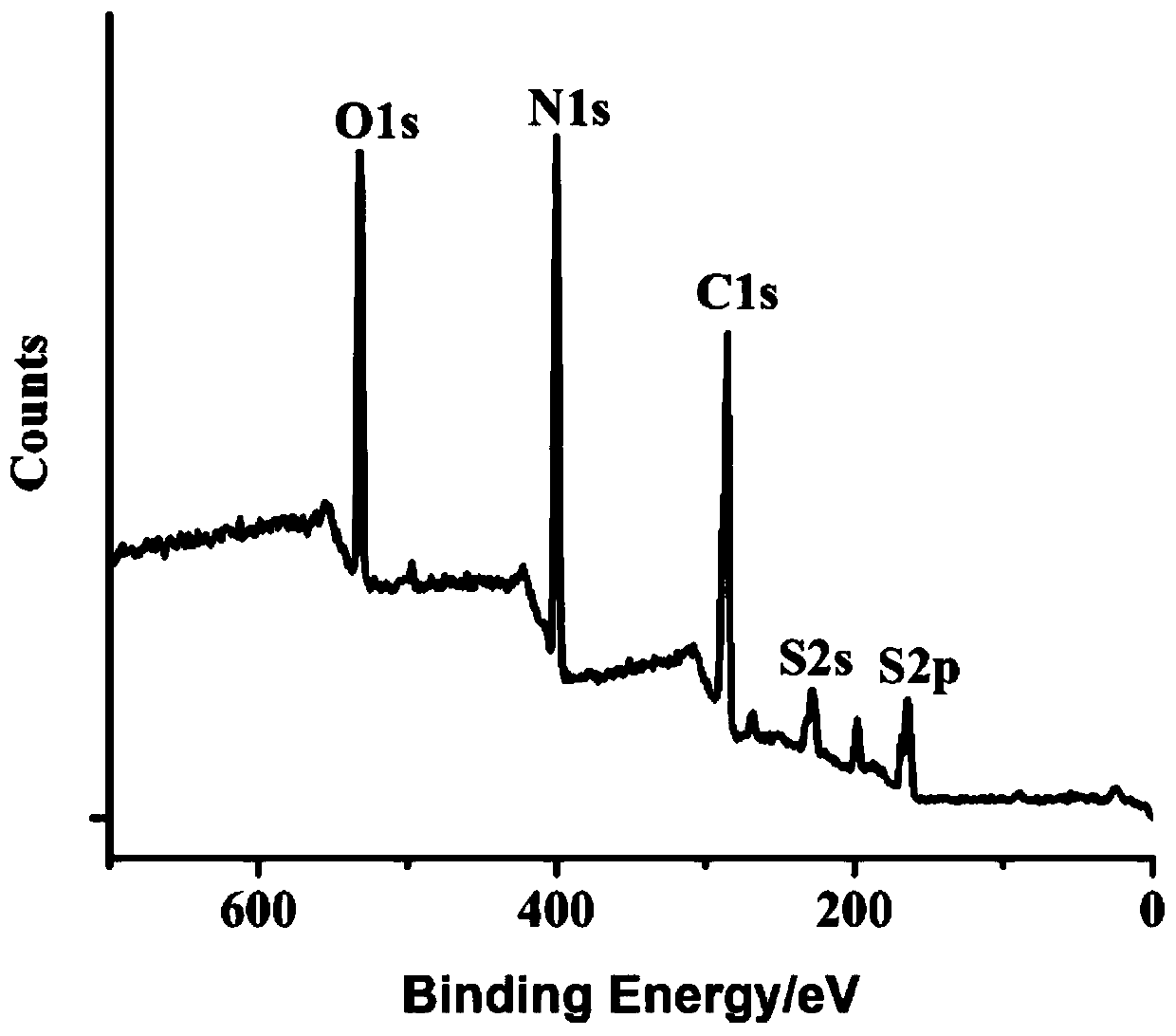

A technology of sulfur doping and fluorescence, which is applied in the field of preparation of fluorescent sulfur-doped nitrogen dots, can solve the problems of increasing the formation mechanism of carbon dots and the difficulty of active sites, inability to effectively control the reaction process, and insufficient reaction raw materials. The effect of changing optoelectronic properties, narrow particle size distribution, and strong photostability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

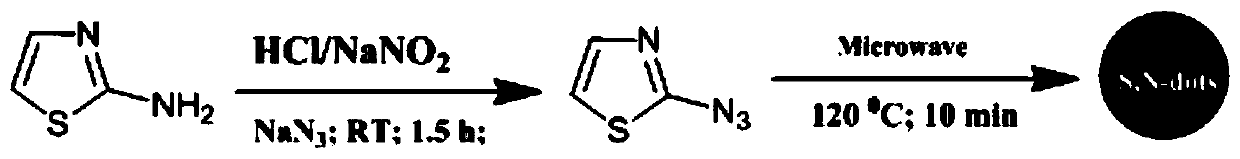

[0035] The invention discloses a preparation method and application of fluorescent sulfur-doped nitrogen dots. The preparation method comprises the following steps:

[0036] S1: Preparation of 2-azidothiazole, the synthetic route is as follows:

[0037]

[0038] S2: dissolving the 2-azidothiazole prepared in step S1 in methanol or ammonia water, performing a microwave heating reaction, and removing the solvent by rotary evaporation after the reaction, to obtain a dry crude product;

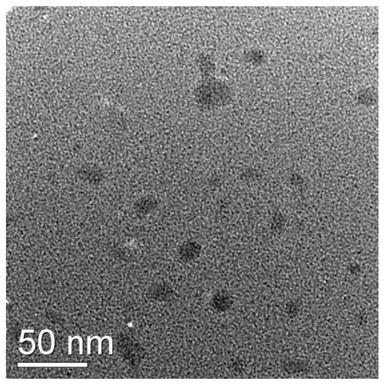

[0039] S3: Disperse the dry crude product obtained in step S2 in ultrapure water, centrifuge at a speed of 10,000r / min for 20min, discard the large particles in the lower layer, collect the supernatant, and pass the supernatant through a 0.2μm filter membrane , to obtain the filtrate;

[0040] S4: Concentrate the filtrate prepared in step S3, and freeze-dry to obtain fluorescent sulfur-doped nitrogen dots in the shape of fleshy floss solid.

Embodiment 1

[0042] see figure 1 , which is a schematic diagram of the synthesis of fluorescent sulfur-doped nitrogen dots of the present invention. The preparation method of fluorescent sulfur-doped nitrogen dots of the present invention comprises the following steps:

[0043] Step S1: Preparation of 2-azidothiazole: Weigh 4.09 g of 2-aminothiazole into a reaction flask, add 32 mL of hydrochloric acid with a concentration of 5.0 mol / L, and stir and add 48 mL of sodium nitrite aqueous solution in an ice-water bath, The mass of sodium nitrite is 2.77g; add 16.3mL sodium azide aqueous solution, wherein the mass of sodium azide is 2.66g; react at room temperature for 2h. After the reaction, extract with water and saturated sodium chloride, collect the organic layer, then dry the organic layer with anhydrous sodium sulfate, and rotary evaporate under reduced pressure to obtain 2-azidothiazole.

[0044] Step S2: Weigh 1.0 g of the 2-azidothiazole prepared in step S1 and dissolve it in 100 mL ...

Embodiment 2

[0048] This example is roughly the same as Example 1, except that the reagents used to synthesize fluorescent sulfur-doped nitrogen dots are different. The method for preparing fluorescent sulfur-doped nitrogen dots described in this example includes the following steps:

[0049] Step S1: Preparation of 2-azidothiazole: Weigh 4.09 g of 2-aminothiazole into a reaction flask, add 32 mL of hydrochloric acid with a concentration of 5.0 mol / L, and stir and add 48 mL of sodium nitrite aqueous solution in an ice-water bath, The mass of sodium nitrite is 2.77g; add 16.3mL sodium azide aqueous solution, wherein the mass of sodium azide is 2.66g; react at room temperature for 2h. After the reaction, extract with water and saturated sodium chloride, collect the organic layer, then dry the organic layer with anhydrous sodium sulfate, and rotary evaporate under reduced pressure to obtain 2-azidothiazole. .

[0050] Step S2: Weigh 1.0 g of the 2-azidothiazole prepared in step S1 and dissol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com