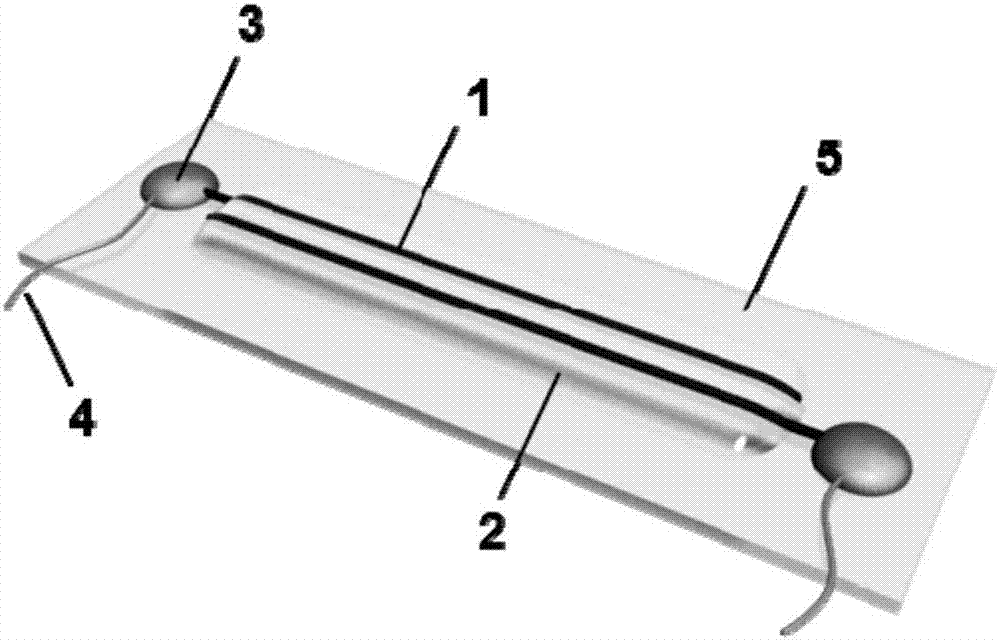

Nitrogen-doped ordered porous high-conductivity graphene fiber, preparation method and application thereof

A technology of graphene fiber and nitrogen doping, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of electrochemical performance improvement and limited space for improvement, no simultaneous realization, poor electrochemical performance, etc. , to achieve the effect of being conducive to electron transmission, good toughness, and improving the total capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

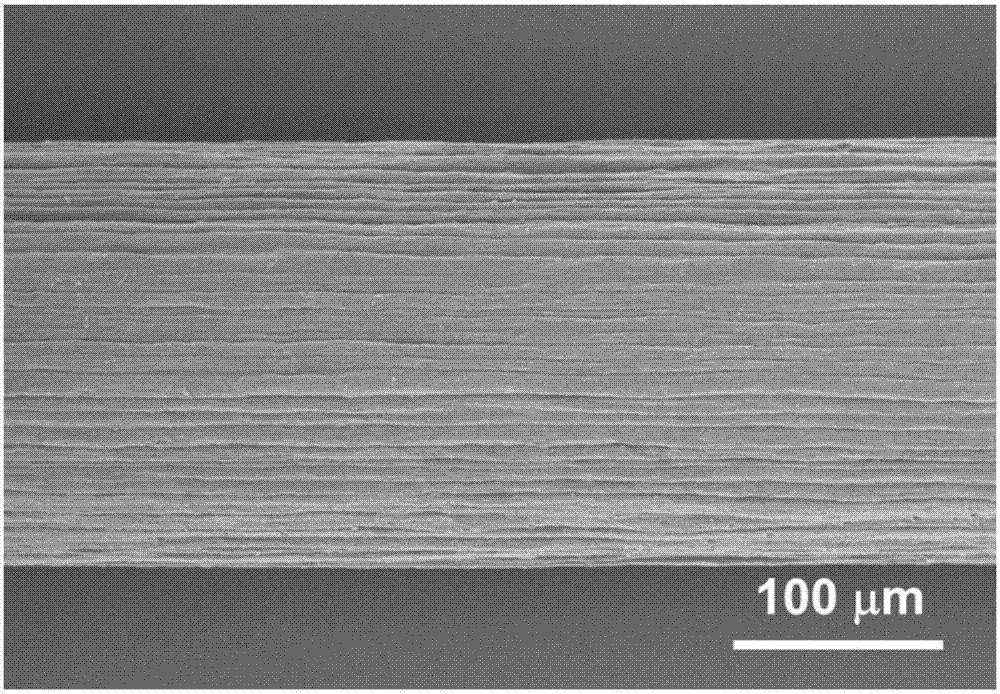

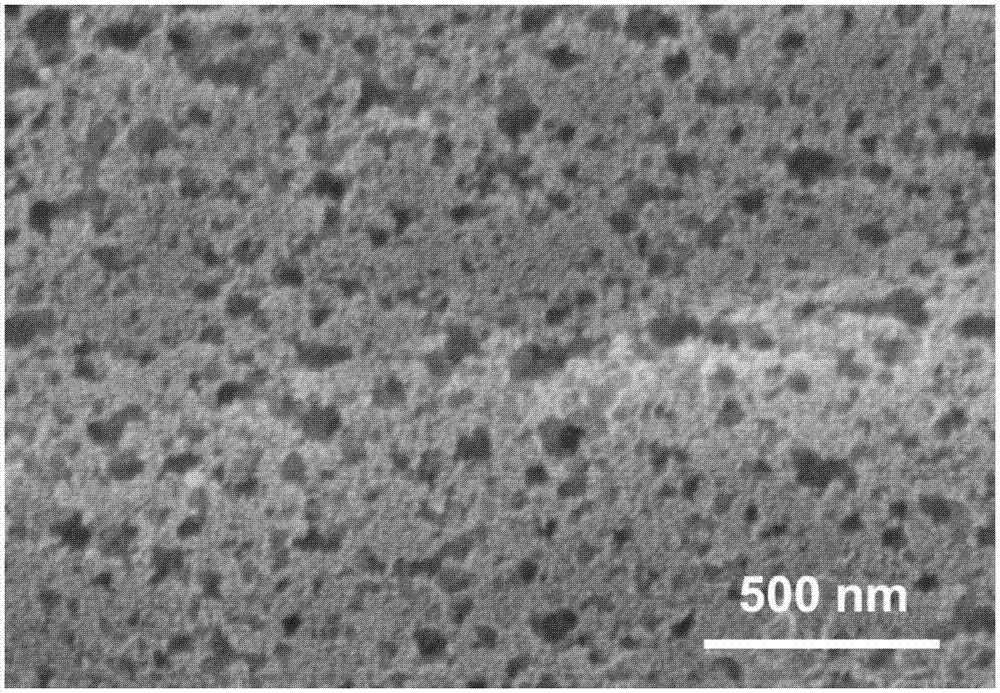

Embodiment 1

[0049] Using 160-mesh natural graphite flakes as raw materials, the graphene oxide aqueous solution was prepared according to the Hummers improved method, and after centrifugation and concentration at a speed of 12,000 rpm or more for 50 minutes, a 14 mg / mL graphene oxide dispersion was obtained; 30 mL of the graphene oxide was dispersed solution and 210 mg urea (mass ratio of graphene oxide to urea is 1:0.5) were fully stirred and mixed evenly, and the above mixed solution was injected into a polytetrafluoroethylene cylinder with an inner diameter of 3 mm through a needle at an extrusion speed of 20 mL / h. Shaped microchannel and sealed at both ends, placed in an oven and heated at 90°C for 4h, then hydrothermally reacted at 160°C for 5h to obtain amino-functionalized graphene fibers; then cooled the cylindrical microchannel to room temperature Open the seals at both ends and dry at 90°C to obtain dehydrated amino-functionalized graphene fibers; the dried amino-functionalized g...

Embodiment 2

[0056] Using 100-mesh natural graphite flakes as raw materials, the graphene oxide aqueous solution was prepared according to Hummers' improved method, and after centrifugation and concentration at a speed of more than 13,000 rpm for 60 minutes, a 20 mg / mL graphene oxide dispersion was obtained; 30 mL of the graphene oxide dispersion was obtained. solution and 150 mg urea (mass ratio of graphene oxide to urea is 1:0.25) were fully stirred and mixed evenly, and the above mixed solution was injected into a polytetrafluoroethylene cylinder with an inner diameter of 4 mm through a needle at an extrusion speed of 10 mL / h. Shaped microchannel and sealed at both ends, placed in an oven and heated at 100°C for 1h, then hydrothermally reacted at 180°C for 4h to obtain amino-functionalized graphene fibers; then cooled the cylindrical microchannel to room temperature Open the seals at both ends, and dry at 80°C to obtain dehydrated amino-functionalized graphene fibers; place the dried ami...

Embodiment 3

[0060] Using 500-mesh natural graphite flakes as raw material, the graphene oxide aqueous solution was prepared according to Hummers' improved method, and after centrifugation and concentration at a speed of more than 10,000 rpm for 30 minutes, a graphene oxide dispersion of 8 mg / mL was obtained; 30 mL of the graphene oxide dispersion was obtained. Liquid and 1200mg of dicyandiamide (the mass ratio of graphene oxide and dicyandiamide is 1:5) are fully stirred and mixed evenly, and the above-mentioned mixture is injected through a needle with an inner diameter of 8 mm at an extrusion speed of 100mL / h. In the glass cylindrical microchannel and sealed at both ends, put it in an oven and heat it at 70°C for 6h, then hydrothermally react at 140°C for 10h to obtain amino-functionalized graphene fibers; then the cylindrical slender pipe After cooling to room temperature, open the seals at both ends, and dry at 100°C to obtain dehydrated amino-functionalized graphene fibers with furthe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com