A blue organic light-emitting diode based on silver nano-cubic plasmon resonance enhancement and its preparation method

A technology of plasmon resonance and light-emitting diodes, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve problems such as reducing device performance, increase energy transfer rate, suppress quenching, improve The effect of efficiency roll-off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

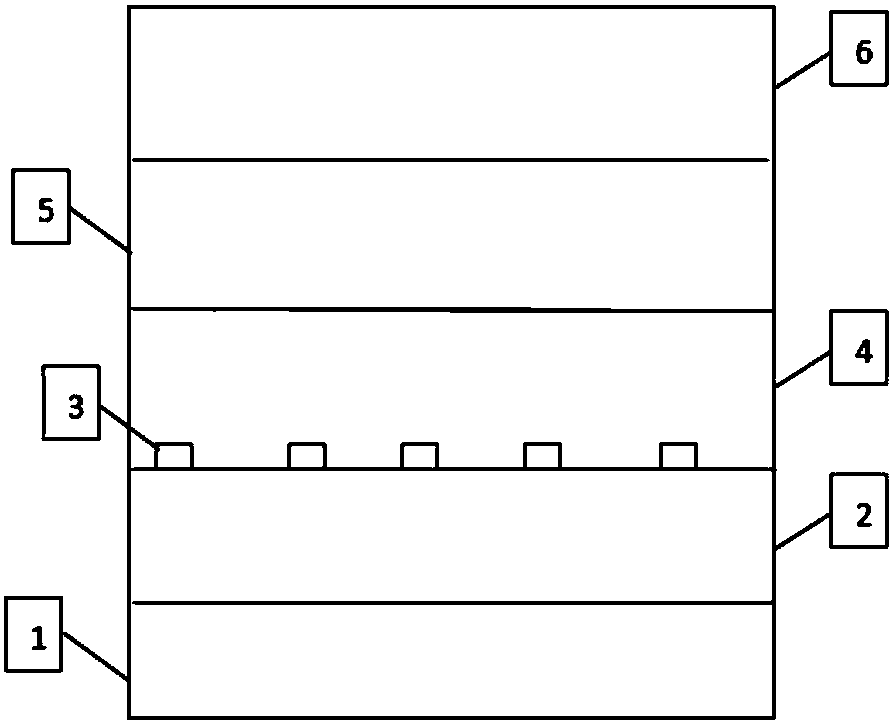

[0034] A blue light organic light emitting diode enhanced by plasmon resonance, the blue light organic light emitting diode is in the order from bottom to top: indium tin oxide (ITO) glass substrate 1, hole transport layer 2, metal nano particle layer 3, Blue light emitting layer 4, electron transport layer 5, composite metal cathode 6. structured as figure 1 shown. The specific method steps are as follows:

[0035] Step 1: Put the ITO glass substrate 1 into acetone, ethanol and deionized water in sequence for ultrasonic cleaning for 10 minutes, blow dry with nitrogen, and place in an oven to dry;

[0036] Step: 2: spin-coat the hole transport layer 2, the material is PEDOT:PSS, the rotation speed is 2000rpm / s, the time is 60s, and the corresponding thickness is 45nm.

[0037] Step 3: Prepare the metal nanoparticle layer 3 by spin coating, and dissolve the silicon dioxide-wrapped silver nanocubes in an ethanol solution with a concentration of 4% at a rotational speed of 200...

Embodiment 2

[0044] A preparation method for silver nanocubes, specifically comprising the steps of:

[0045] Step 1: After taking 4ml of ethylene glycol solution in the reagent bottle, put the reagent bottle into an oil bath and heat it to 150°C for at least 40 minutes;

[0046] Step 2: Weigh 0.081g of PVP at room temperature, mix with 4ml of ethylene glycol solution and stir until fully dissolved; weigh 0.005g of sodium hydrosulfide, mix with 3ml of ethylene glycol solution and stir until Fully dissolve; weigh 0.108g of silver nitrate, mix with 1.25ml of ethylene glycol solution and stir until fully dissolved; mix the prepared solution evenly at room temperature, and let it stand for use;

[0047] Step 3: Add 100 μl of ethylene glycol dropwise to the prepared sodium hydrosulfide mixture to dilute it 10 times, and store it at room temperature until use.

[0048] Step 4: In the oil bath temperature range of 148-150 ° C, while the ethylene glycol solution is kept under the stirring conditi...

Embodiment 3

[0054] A method for encapsulating silver nanocubes, specifically comprising the steps of:

[0055] Step 1: At room temperature, take about half (950ul) of the silver nanocubic solution and centrifuge and wash twice at 12000rpm / s, each time for 10min. Add 10ml of ethanol, ultrasonic 15min.

[0056] Step 2: Add 1.4ml of deionized water and 160ul of ammonia water at room temperature and 500rpm / s, and stir for 5min. Add TEOS: ethanol solution (1:4) 3ul, stir for about 30min. Add 3ul of TEOS:ethanol solution (1:4) again, and stir for about 30min.

[0057] Step 3: At room temperature, under the condition of 500rpm / s, add 3ul TEOS: ethanol solution and stir for about 12h. Put into centrifuge subsequently, centrifuge wash 10min under the condition of 12000rpm / s.

[0058] Such as Figure 5 Shown are the absorption lines of silver nanocubes prepared in Example 3 before and after being wrapped with silicon dioxide. It can be seen from the figure that after wrapping silicon dioxide,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com