Microsphere-shaped double-comb type block polymer profile control and flooding agent and preparation method thereof

A block polymer, double-comb type technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of short cross-linking time, poor fluidity, and difficulty in going deep into the formation, and achieves improved solubility, increased Temperature resistance, the effect of increasing the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

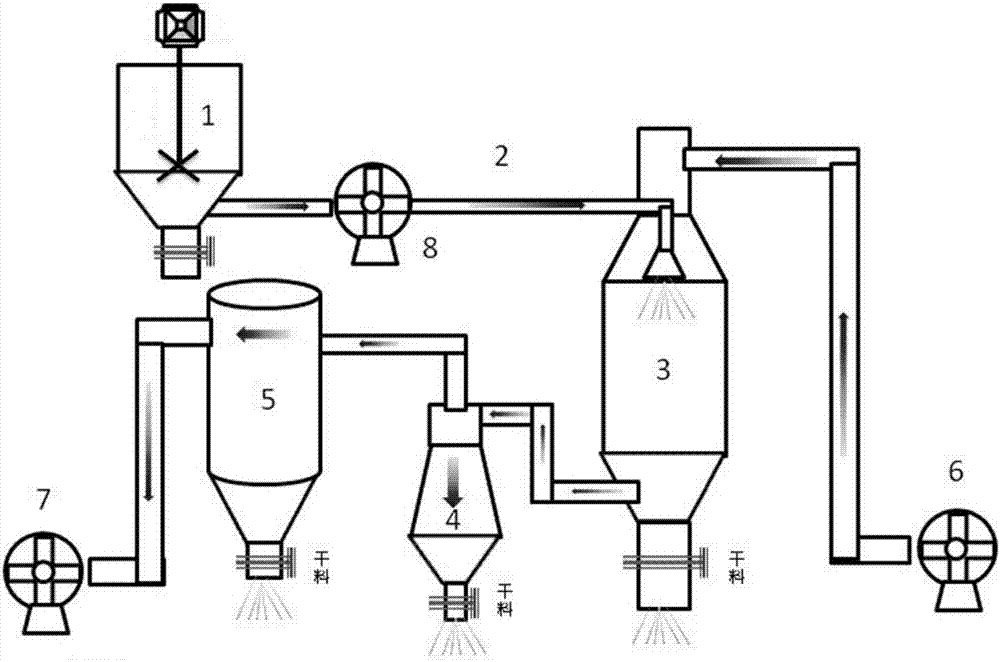

[0044] This embodiment firstly provides a kind of aerosol equipment, its structure is as follows figure 1 As shown, the aerosol device includes:

[0045] Mother liquor tank 1, three spray guns 2, first screening tower 3, second screening tower 4, third screening tower 5, blower 6 and induced draft fan 7;

[0046] Wherein, the mother liquor tank 1 is communicated with the first screening tower 3, and a spray gun 2 is arranged between the mother liquor tank 1 and the first screening tower 3; a plunger pump 8 is arranged on the spray gun 2; the first screening tower 3, the second The screening tower 4 and the third screening tower 5 are connected in sequence; the blower 6 is connected with the first screening tower 3; the induced draft fan 7 is connected with the third screening tower 5; the gun head of the spray gun 2 is set on the first screening tower 3 The upper end of the interior.

[0047] This embodiment provides a method for preparing a microspherical double-comb block ...

Embodiment 2

[0056] This embodiment provides a method for preparing a microspherical double-comb block polymer control and displacement agent, which specifically includes the following steps:

[0057] (1) Solution preparation: in molar parts, acrylamide monomer, epoxyoctane, 2-acrylamido-2-methylpropanesulfonic acid and acrylic acid monomer are prepared according to the ratio of 50:23:19:7 Concentration is 28% aqueous solution, add pH adjusting agent (sodium bicarbonate), adjust pH to 7.5;

[0058] (2) Polymerization process: Continuously feed 99.999% high-purity nitrogen at a constant temperature of 12° C. After 40 minutes, redox composite initiators (composed of diethylenetriamine, potassium persulfate, and potassium bisulfite, each component’s The mass ratio is 3:2:1), and this process continues to feed high-purity nitrogen, and the addition amount of redox composite initiator is monomer (monomer refers to acrylamide monomer, and hexane oxide is prepared to have a concentration of 28% ...

Embodiment 3

[0063] This embodiment provides a method for preparing a microspherical double-comb block polymer control and displacement agent, which specifically includes the following steps:

[0064] (1) Solution preparation: in molar parts, acrylamide monomer, 1,2-epoxydodecane, 2-acrylamidotetradecanesulfonic acid and acrylic acid monomer are in the ratio of 45:25:12:5 It is prepared into an aqueous solution with a concentration of 35%, and a pH regulator (sodium bicarbonate) is added to adjust the pH to 7;

[0065] (2) Polymerization process: Continuously feed 99.999% high-purity nitrogen at a constant temperature of 15°C, and add redox composite initiators (by N,N,N',N'-tetraethylethylenediamine, persulfuric acid) in sequence after 30 minutes Ammonium, ammonium bisulfite, the mass ratio of each component is 4:2:1), this process continues to feed high-purity nitrogen, the addition of redox composite initiator is monomer (monomer refers to acrylamide mono Monomer and hexane oxide are p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| water phase permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com