Ceramic material as well as manufacturing method thereof

A technology for ceramic materials and ceramic products, which is applied in the field of reuse of fly ash-extracted aluminum tailings, can solve problems such as waste of silicon resources, white mud pollution, etc., and achieves the effects of low cost, low water absorption, and easy availability of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Take 500kg of white clay containing 22% (mass content) of alumina (from Shenhua Zhuneng Company), add 25kg of foaming agent silicon carbide, 200kg of flux feldspar, 275kg of flux glass powder, and 2.5kg of sodium tripolyphosphate as grinding aid ;

[0039] Put the above materials into a ball mill, add 660kg of water, and grind;

[0040] The ground slurry is spray dried at 200°C;

[0041] Send the dried materials to the silo for 48 hours;

[0042] The stale material is semi-dry pressed with a pressure forming machine;

[0043] Dry the formed green body;

[0044] The dried green body is fired in a tunnel kiln at a firing temperature of 950°C for 4 hours.

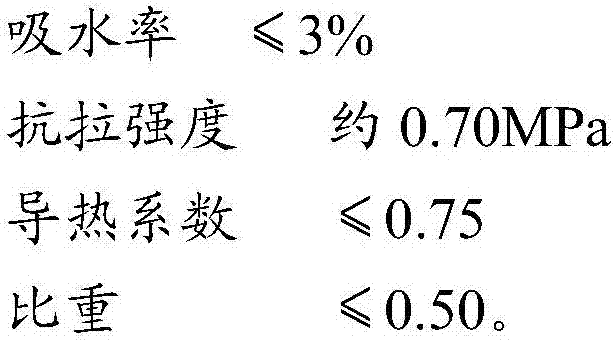

[0045] The prepared ceramic material was tested. Among them, the performance parameters of the ceramic material were: fire resistance class A; water absorption rate of 2.6%, tensile strength of 0.70 MPa, thermal conductivity of 0.7, and specific gravity of 0.45. Detect the content of ceramic materials, including 75% SiO 2 , 19% A...

Embodiment 2

[0047] Take 600kg of white mud containing 18% alumina (from Shenhua Zhuneng Company), add 30kg of free carbon of blowing agent, 170kg of feldspar, 200kg of flux glass powder, and 2.5kg of water glass as grinding aid;

[0048] Put the above materials into a ball mill, add 660kg of water, and grind;

[0049] Spray-dry the ground slurry at 260°C;

[0050] Send the dried materials to the silo;

[0051] The stale material is semi-dry pressed and formed by a press;

[0052] Dry the formed green body;

[0053] The dried green body is fired in a roller kiln at a firing temperature of 1300°C.

[0054] The prepared ceramic material was tested. Among them, the performance parameters of the ceramic material were: fire resistance class A; water absorption rate of 3%, tensile strength of 0.70 MPa, thermal conductivity of 0.65, and specific gravity of 0.4. Detect the content of ceramic materials, including 70% SiO 2 , 22% Al 2 O 3 , 8% Na 2 O and K 2 O.

Embodiment 3

[0056] Take 700kg of white clay containing 25% alumina (from Shenhua Zhunneng Company), add 25kg of blowing agent iron oxide, 125kg of feldspar, 150kg of fluorite, and 2.5kg of water glass;

[0057] Put the above materials into a ball mill, add 600kg of water, and grind;

[0058] Spray-dry the ground slurry at 300°C;

[0059] Send the dried materials to the silo;

[0060] The stale material is semi-dry pressed and formed by a press;

[0061] Dry the formed green body;

[0062] The dried green body is fired in a tunnel kiln at a firing temperature of 1450°C.

[0063] The prepared ceramic material is tested, wherein the performance parameters of the ceramic material are: fireproof performance class A; water absorption rate of 2.8%, tensile strength of 0.70 MPa, thermal conductivity of 0.6, and specific gravity of 0.45. Detect the content of ceramic materials, including 65% SiO 2 , 25% Al 2 O 3 , 10% Na 2 O and K 2 O.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com